INTRODUCTION

4

Congratulations on purchasing the GRR-RIPPER 3D Pushblock system. Over 5,000 hours

of engineering, 45 design concepts and prototypes went into making the GRR-RIPPER

the safest, most precise pushblock available. Before using your GRR-RIPPER, read

through this manual to familiarize yourself with the GRR-RIPPER and how it works.

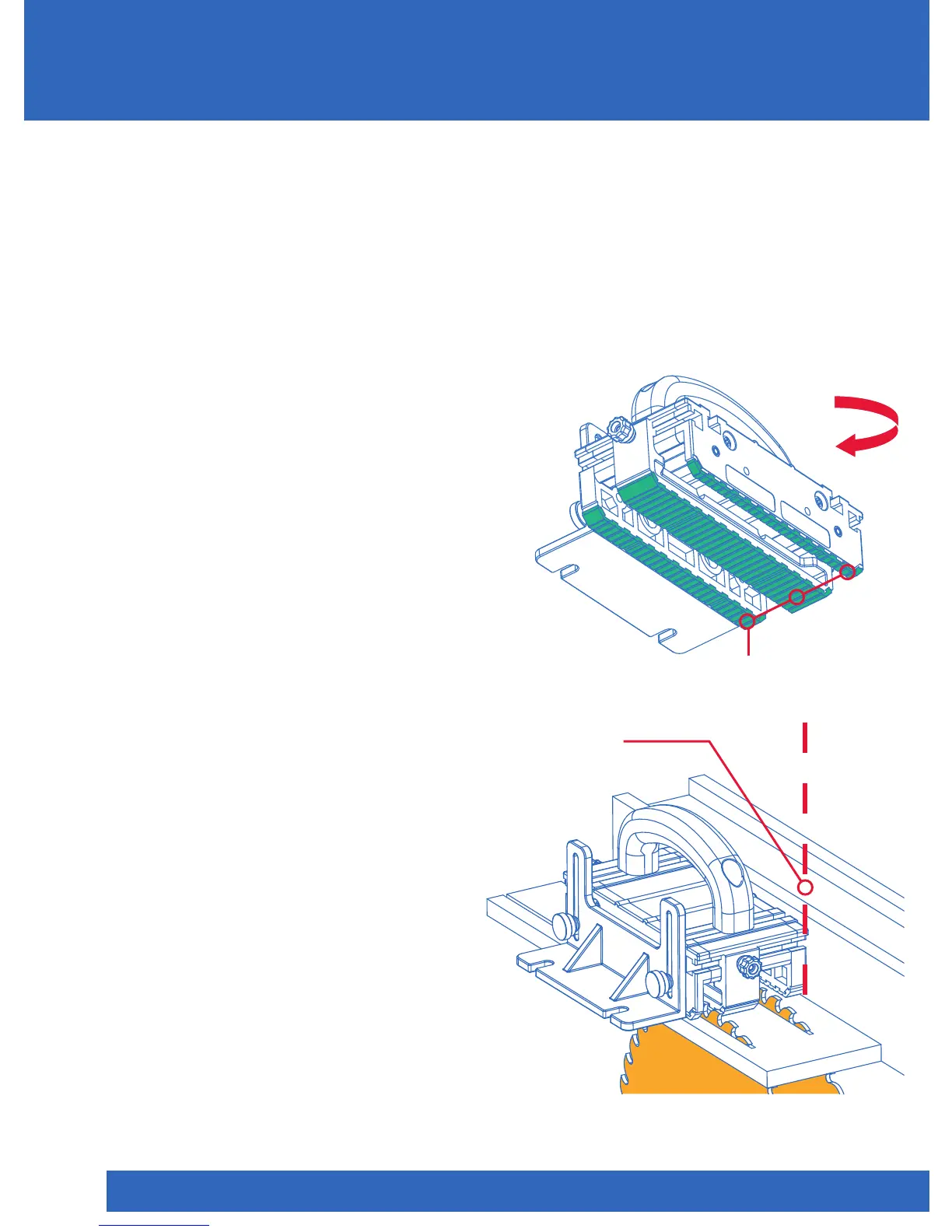

The following is a general overview of the way the

GRR-RIPPER is designed to work:

The GRR-RIPPER uses grooved non-slip

pads (Green GRR-RIP

®

) to hold down and

feed your workpiece through the cutting

element. The tool can be rotated end-

to-end to for use with either the 1/2” or

1/4” Side Leg against the fence.

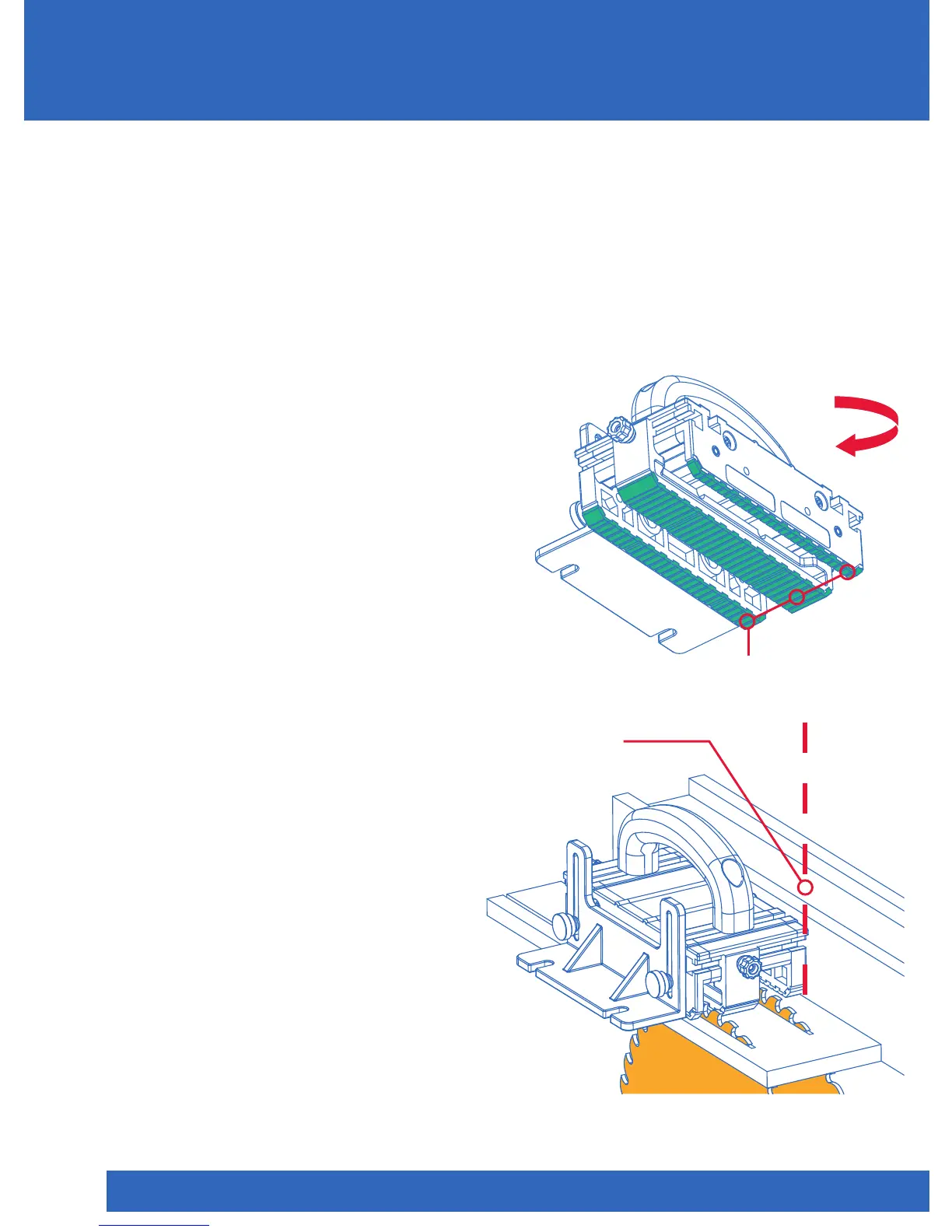

With the rip fence set parallel to the saw

blade, the GRR-RIPPER glides against

the rip fence to ensure a parallel feed. It

also keeps both sides of the workpiece

in their original positions throughout the

cutting process, which virtually prevents

the possibility of kickback and burning.

With bare-hand feeding eliminated,

nger injury is greatly reduced.

The GRR-RIPPER feeds the workpiece

as the saw blade passes through either

its right or left tunnel. This feature

virtually eliminates the need for bare-

hand feeding when used properly.

The GRR-RIPPER is a protective guard

that you hold throughout the

cutting operation.

GRR-RIPPER

glides against

rip fence

Green GRR-RIP

®

Reversible

Figure 1

Figure 2

Loading...

Loading...