This document is strictly private and confidential, reproduction without Micropack approval is prohibited. © Micropack Engineering Ltd, 2018

The following guidelines are intended to assist with the electrical design and engineering of

systems where it is intended that flame detectors will be used

.

4.1 Power Supply

The detector requires an absolute minimum supply voltage of 18Vdc, as measured at the

detector

terminals. The system power supply voltage and power distribution should be

arranged such

that on the longest cable run the detector(s) has a supply voltage of greater than

18Vdc.

4.2 Cable Selection

Cable to be used for installation is to be selected with a temperature rating of greater than 25

degrees Celsius above the maximum ambient temperature.

The metric cable entries are fitted with an internal stop. This internal stop has an IP washer

mounted directly above it. Ensure this is fitted to maintain the ingress protection. This will result

in threads of the cable gland being visible. Do not over tighten.

The installation and local regulations and standards determine the overall cable specification.

This section specifies suitable cable characteristics to ensure correct operation of the flame

detector.

4.2.1 DC Power

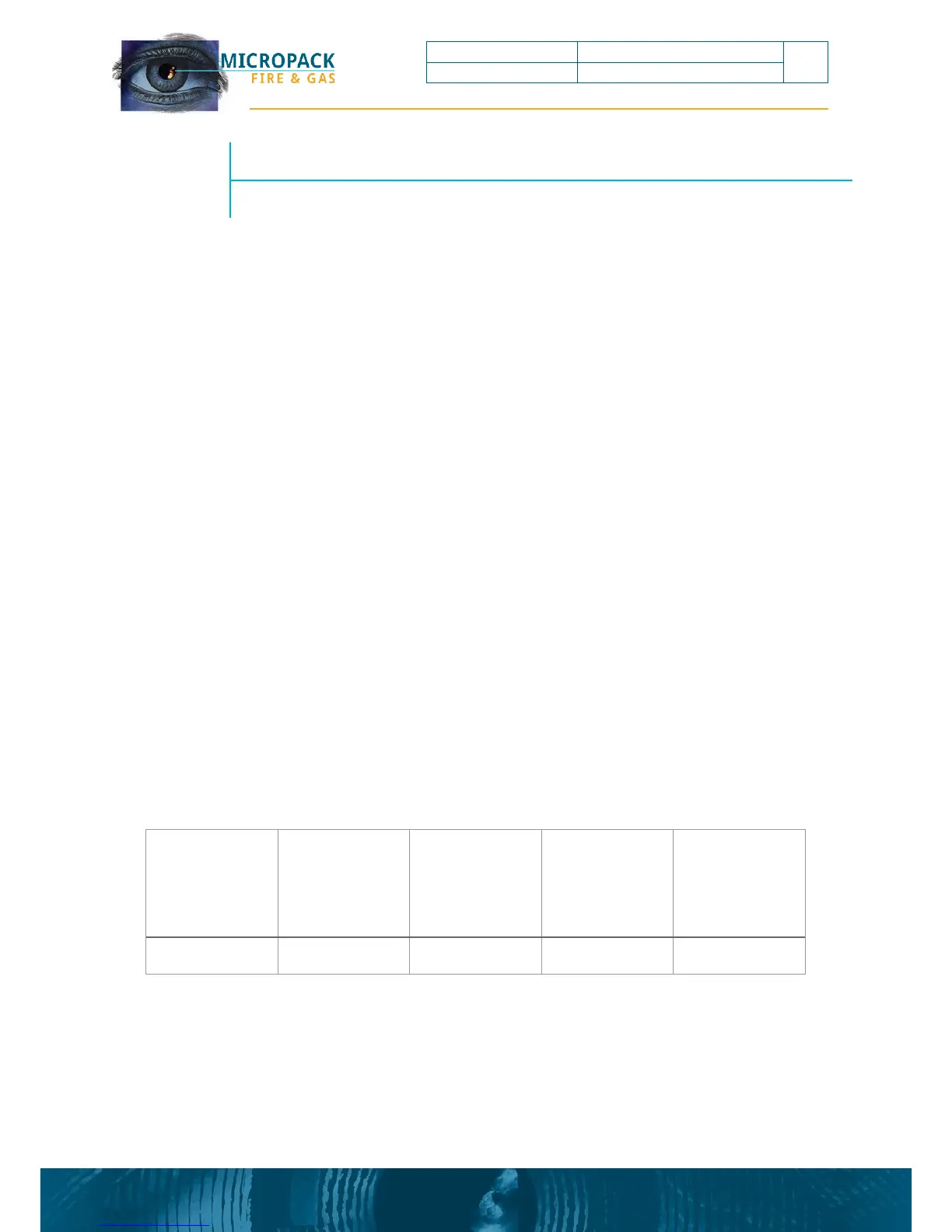

NOTE: Table 2 shows an absolute maximum for cable length; try not to approach this value.

DO NOT ground any cable shields at the detector housing.

Table 2: Maximum Cable Lengths (24Vdc supply)

Installation

based on 24V

nominal supply

Number of

Flame Detectors

Maximum Power

(W)

Maximum Cable

Length (m) with

1.5mm2

Conductors

(12Ω/km)

Maximum Cable

Length (m)with

2.5mm2

Conductors

(7.6Ω/km)

Detector 1 12W @ 24Vdc 500 Metres 780 Metres

Loading...

Loading...