FDS303 Safety and Technical Manual

Rev: 1.7 ECN: 4535 Ref: 3303.0001

This document is strictly private and confidential, reproduction without Micropack approval is prohibited. © Micropack Engineering Ltd, 2018

Appendix F - IEC 61508 Failure Rate Data

IEC 61508: ed 2, 2010

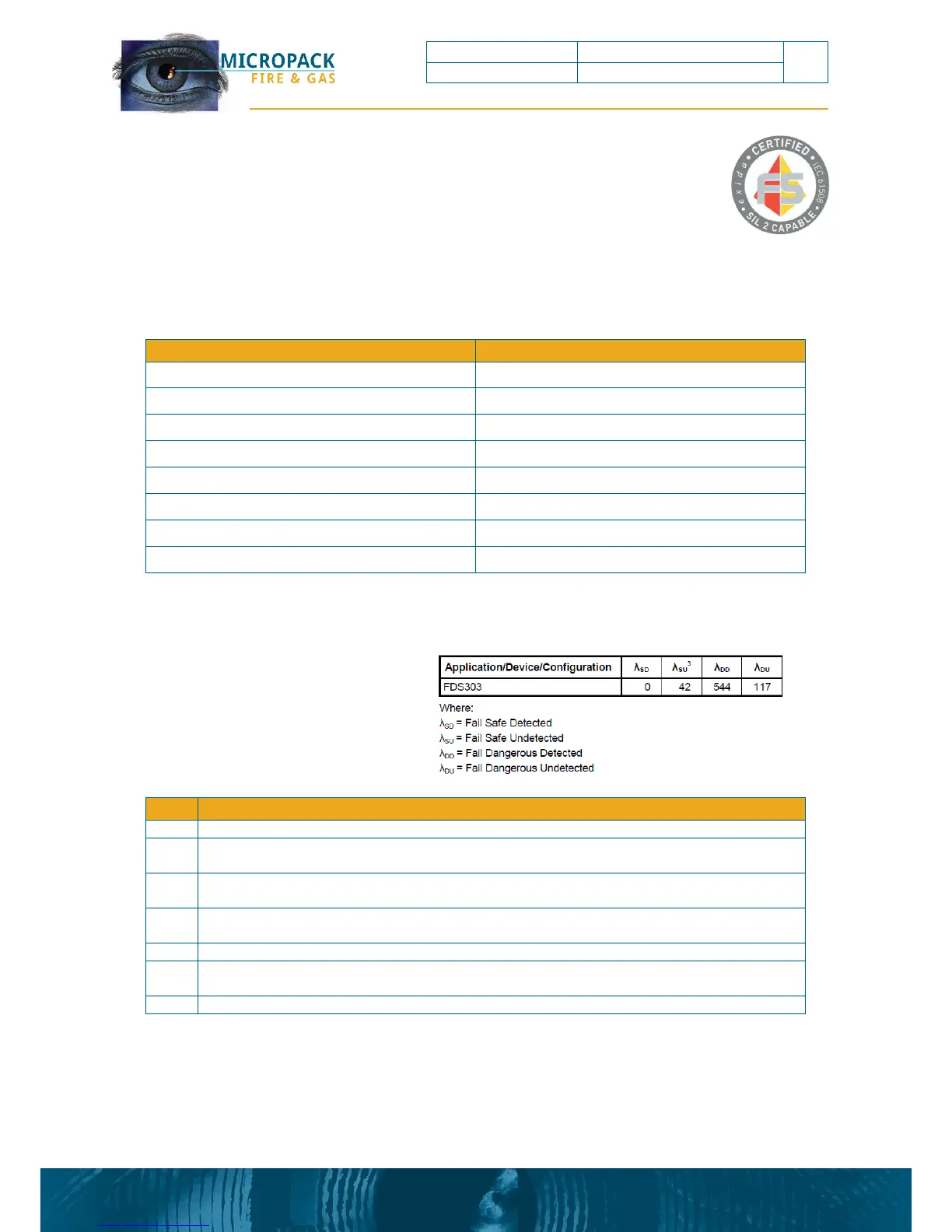

Using reliability data extracted from the exida Electrical and Mechanical

Component Reliability Handbook the following failure rates resulted from the FDS303 FMEDA.

MAXIMUM DIGNOSTIC TEST INTERVAL – 15 minutes.

The useful lifetime of critical components is predicted to be

50 years (Ref: Report No.: MP 17/10-

145 R001 V1 R1).

Fail Safe Undetected 42

Fail Dangerous Detected 544

Fail Detected (detected by internal diagnostics) 488

Fail High (detected by logic solver) 13

Fail low (detected by logic solver) 43

Fail Dangerous Undetected 117

No Effect 1547

Annunciation Undetected 11

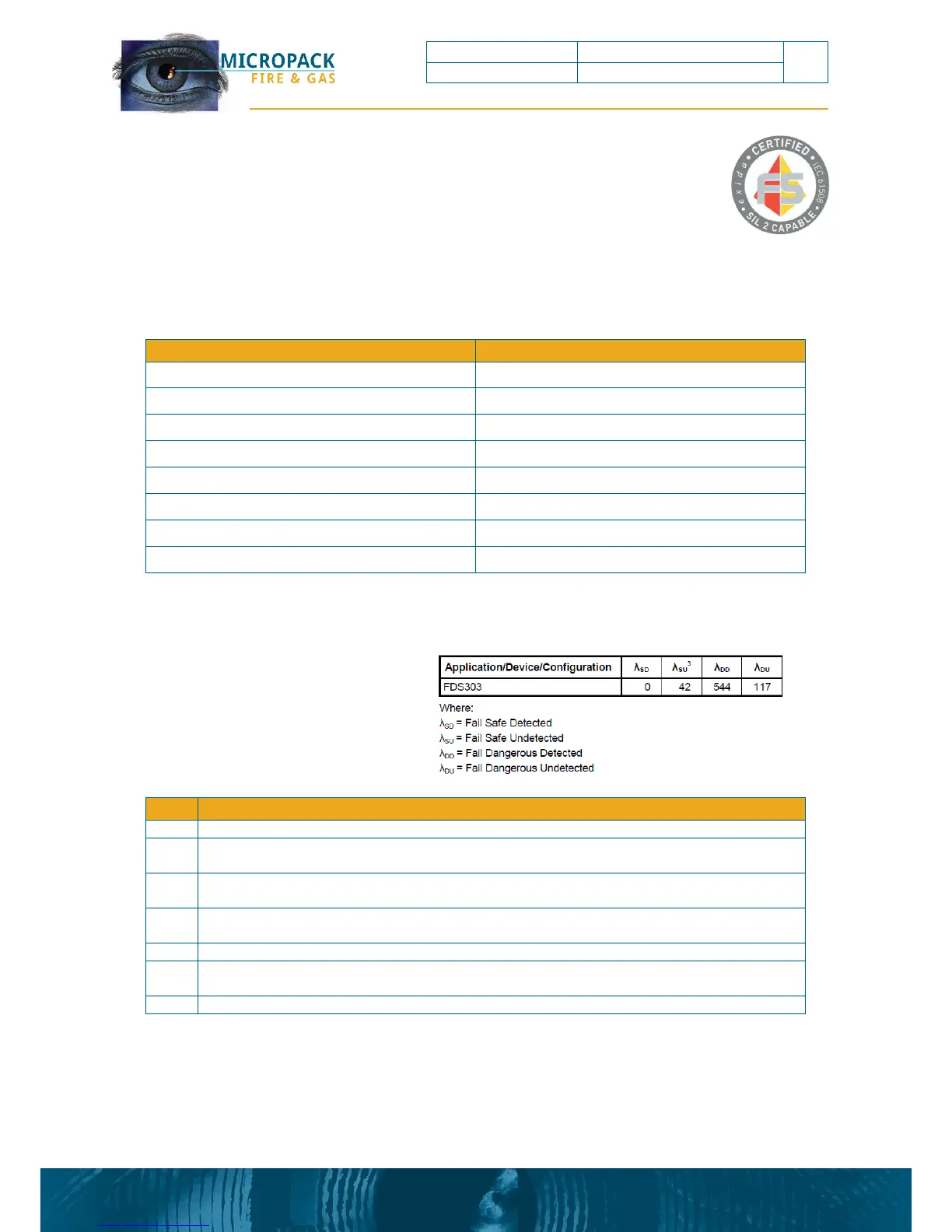

The FDS303 is classified as a Type B Element according to IEC 61508, having a hardware fault

tolerance of 0. Therefore, based on the SFF of 94.83% a design can meet SIL 2 @ HFT=0 when the

FDS303 is used as the only component in a SIF Sub-assembly.

Proof Testing

Bypass the safety function and take appropriate action to avoid false trip.

(Optional) Use RS485 communications to retrieve and diagnostics and take appropriate

action.

Use the test torch to force the FDS303 into alarm state. Verify that LED, alarm relay/0-

20mA outputs indicate alarm (as required)

Wait for detector alarm signal to unlatch. Verify that the LED, alarm relay/0-20mA outputs

no longer indicate alarm.

Inspect enclosure for any leaks, visible damage or dirty optics.

Perform the periodic inspection and maintenance procedure from the FDS303 safety and

technical manual.

Remove the bypass and otherwise restore normal operation.

Proof testing should be carried out on a yearly basis, showing a probability of failure on demand

average (PFD

AVG

) of 6.82E-03. The following represents a suggested proof test.

Personnel carrying out commissioning, testing and maintenance on this device shall be

sufficiently competent and experienced to do so.

Loading...

Loading...