MILK COOLING TANK MAINTENANCE - CLEANING

The milk cooling tank has special maintenance and cleaning requirements. The machine is used for the refrigerating and the

conservation of milk, so it requires daily and efficient cleaning. The cleaning of the inside of the tank, which is in contact with

the milk, as well as the external surface of the milk cooling tank, should be performed with hot water and a suitable smooth

brush (picture 5).

Before every cleaning or maintenance job, ensure that the milk cooling tank has been properly disconnected from

electricity.

Cleaning and maintenance are performed after the machine has been unplugged from electricity.

Clean the external and internal surfaces of the tank daily.

10.1 CLEANING THE TANK

Empty the tank and rinse it with cold water in order to remove remaining milk residue. Then, clean the tank carefully with hot

water at about 45

o

C, using detergents only used for foods.

Rinse the interior of the tank out with plenty of cold water and scrub it with a brush suitable for commissary until it is thor-

oughly cleaned.

After cleaning the tank, dry it thoroughly by using an absorbent paper towel or special of cloth that does not leave

thrum, which can cause infection or electric shock.

Clean the control panel by using a wet piece of cloth after disconnecting the machine from electricity.

10.2 CLEANING THE REFRIGERATING UNIT CONDENSER

It is absolutely necessary to periodically clean the condenser of the refrigerating unit, in order to assure long-lasting and relia-

ble operation of the milk cooling tank.

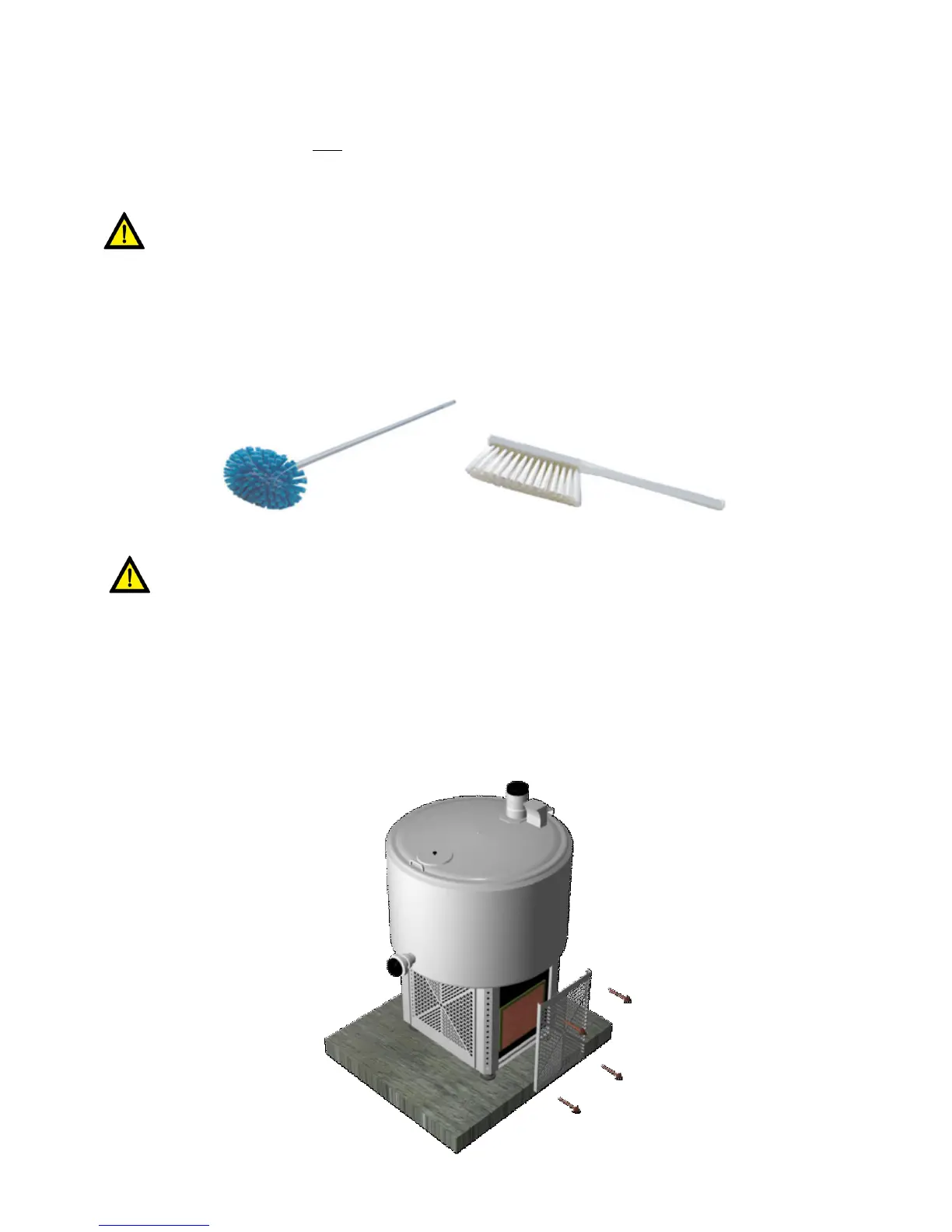

Clean the condenser by first unscrewing the screws that attach the lateral cover at the side of the condenser, and removing

the lateral cover. You may then clean the condenser by using pressurized air. You can also clean the condenser by carefully

using a brush in order to remove dust and other debris from its surface.

DO NOT USE WATER TO CLEAN THE CONDENSER.

Loading...

Loading...