OM-284208 Page 31

F

Complete Parts List is available at www.MillerWelds.com

SECTION 7 – OPERATION

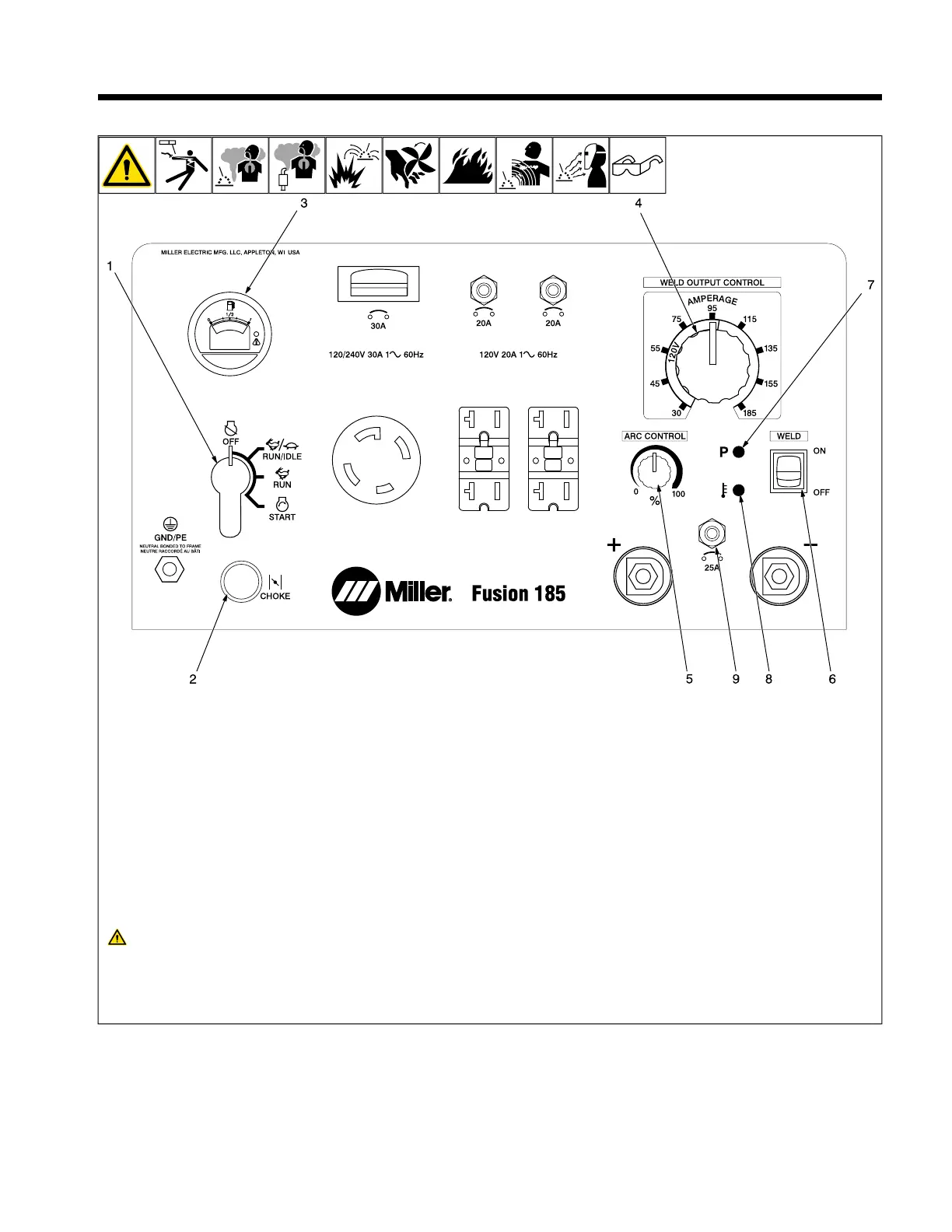

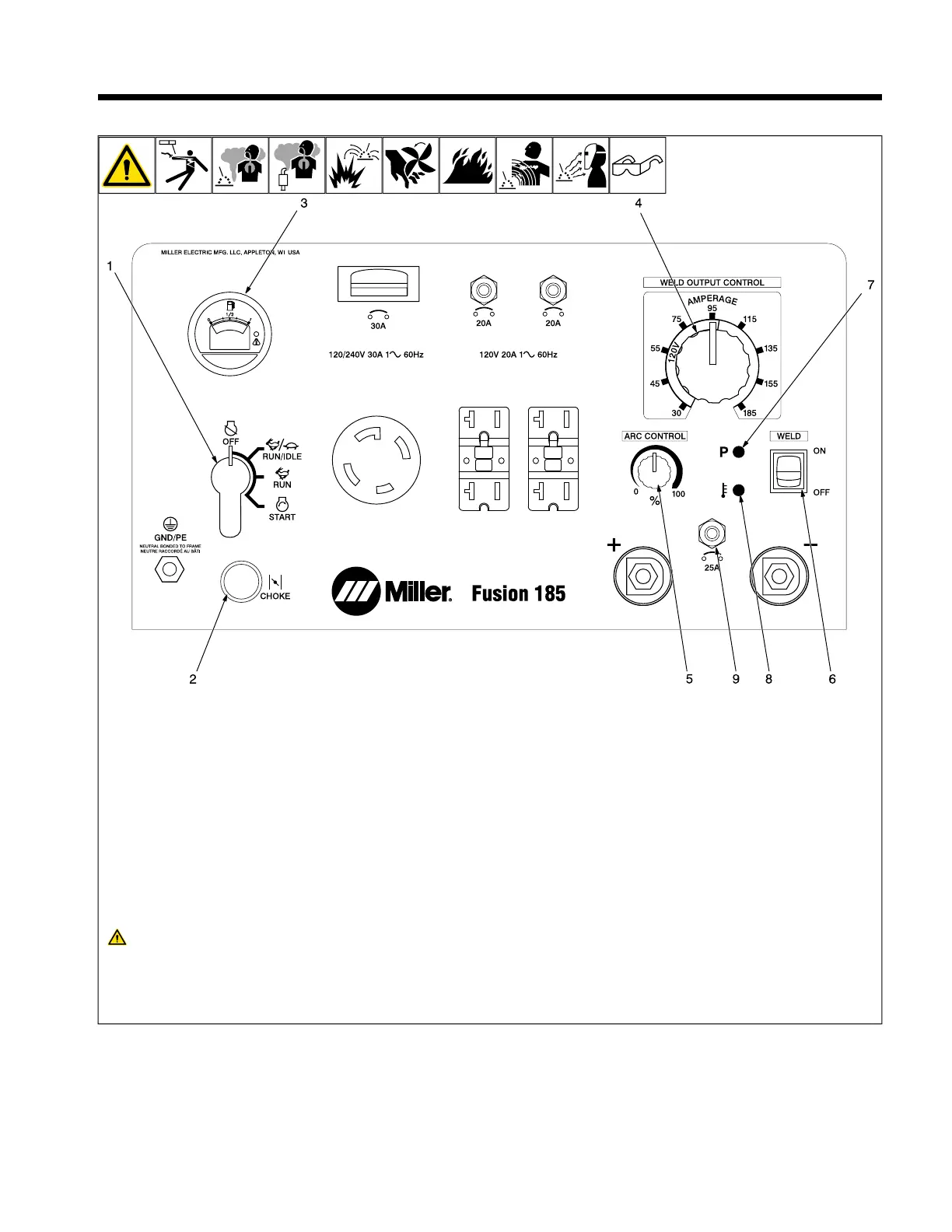

7-1. Front Panel Controls

1 Engine Control Switch

Use switch to start engine and stop engine.

In Run position, engine runs at weld/power

speed.

2 Choke Control

Changes fuel/air mixture.

To Start:

l Open fuel valve (see Section 5-6).

l Pull out choke.

l Turn Engine Control switch to start posi-

tion and hold until engine starts.

l Slowly push in choke as engine warms.

If the engine does not start, let en-

gine come to a complete stop before

attempting restart.

To Stop:

Turn Engine switch to Off.

F

Always close fuel valve after stopping

unit. Moving unit with fuel valve open

may cause carburetor flooding and

make starting difficult.

3 Engine Hour Meter/Idle Control

4 Weld Output Control

Use control to select weld amperage. Con-

trol may be adjusted while welding.

5 Arc Control

When Arc Control is set at 0% (softest),

there is no added dig current. Weld output is

constant current based on the weld

command.

When Arc Control is set at 100% (stiffest),

the dig threshold is 19.5 volts, and the maxi-

mum amount of dig current is added based

on the weld command setting. As the Arc

Control setting is reduced from 100%, the

dig threshold is lowered, resulting in less dig

current added and a softer arc.

6 Weld On/Off Switch

Use switch to turn on welder. Engine power

can be used with the weld power cable

plugged into generator or wall power.

7 Power Indicator LED

LED must be on to weld.

8 Overtemp/Fault Code LED

9 Supplementary Protector CB4

CB4 protects weld inverter when plugged in-

to generator or utility power. If supplementa-

ry protector opens, there will be no weld

output.

Loading...

Loading...