What to do if Miller Welding System shows Power Source Overtemp Fault F64?

- DDaniel BassAug 20, 2025

If the Miller Welding System shows a Power Source Overtemp Fault (F64), make sure that the power source vents and wind tunnel are not blocked.

What to do if Miller Welding System shows Power Source Overtemp Fault F64?

If the Miller Welding System shows a Power Source Overtemp Fault (F64), make sure that the power source vents and wind tunnel are not blocked.

What to do if Miller ProHeat 35 OM-222 166F indicates Cable Connection Fault F68?

If the Miller Welding System indicates a Cable Connection Fault (F68), check for loose or open output connections. Verify that all output cables are the same type and that the receptacle plug is properly connected.

What to do if Miller Welding System displays Coolant Flow Fault F61?

If the Miller Welding System displays a Coolant Flow Fault (F61), check for any coolant leaks and clean any coolant blockages. Also, inspect the coolant filter and level, and check the coolant connections.

What to do if Miller ProHeat 35 OM-222 166F Welding System displays Cable Connection limit condition L13?

If the Miller Welding System displays a Cable Connection (L13) limit condition, check for any loose or open output connections. Ensure all output cables are of the same type, and verify the receptacle plug is connected correctly.

What to do if Miller Welding System indicates Power Source Overtemp Limit L12?

If the Miller Welding System indicates a Power Source Overtemp Limit (L12), check for blocked vents and clean the wind tunnel heat sinks.

What to do if Miller ProHeat 35 OM-222 166F Welding System displays Temperature Sensor Fault F60?

If the Miller Welding System displays a Temperature Sensor Fault (F60), check the control TC connections and the control TC extension cable.

What to do if Miller ProHeat 35 OM-222 166F Welding System indicates a Line Voltage Fault F63?

If the Miller Welding System indicates a Line Voltage Fault (F63), check the line voltage.

What to do if Miller ProHeat 35 OM-222 166F Welding System displays Isolation Fault F62?

If the Miller Welding System displays an Isolation Fault (F62), check for any exposed conductors and clean any moisture on the cables.

How to fix Thermocouple #6 Open (L06) limit condition on Miller ProHeat 35 OM-222 166F?

To address the Thermocouple #6 Open (L06) limit condition on your Miller Welding System, check the temperature sensor for any opens and repair if needed. Alternatively, switch to a backup temperature sensor.

How to fix Thermocouple #5 Open (L05) limit condition on Miller Welding System?

To address the Thermocouple #5 Open (L05) limit condition on your Miller Welding System, check the temperature sensor for any opens and repair if needed. Alternatively, switch to a backup temperature sensor.

| Brand | Miller |

|---|---|

| Model | ProHeat 35 OM-222 166F |

| Category | Welding System |

| Language | English |

Explains symbols used to denote hazards and precautions.

Details hazards related to induction heating operations.

Explains additional symbols for specific operational contexts.

Lists California's Proposition 65 warnings for chemicals.

Lists key safety standards and their sources.

Discusses electromagnetic field considerations in induction heating.

Explains the meaning of various warning labels used on the equipment.

Describes the information found on the CE rating label.

Lists and defines symbols specific to CE products.

Provides technical specifications for the ProHeat 35 unit.

Guides on choosing a suitable location for the unit.

Advises on safe handling to prevent tipping.

Details electrical requirements and wiring guidelines.

Step-by-step guide for connecting power to 460/575V models.

Step-by-step guide for connecting power to 400/460V models.

Explains how to connect output cables for various configurations.

Details the RC14 receptacle and its connections.

Lists socket assignments and their functions for the RC14.

Explains the RC9 receptacle and its wiring.

Provides socket details for temperature recorder connections.

Describes the secondary insulation protection system.

Details the 115V AC receptacle and its protective device.

Guides on proper placement of thermocouples for accurate readings.

Details the process for welding thermocouples to workpieces.

Explains the use of contact temperature sensors as an alternative.

Guides on correctly positioning the temperature probe.

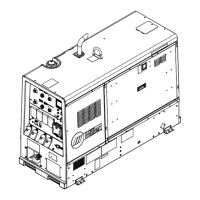

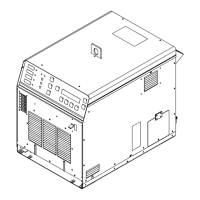

Identifies and describes the various controls on the unit's panel.

Lists essential safety equipment required during operation.

Provides an overview of the ProHeat 35 system's design and function.

Guides on configuring the system setup parameters.

Explains how to set up programs for heating processes.

Details control based on feedback from thermocouples.

Describes the Preheat process setup.

Describes the Bake-Out process setup.

Describes the PWHT process setup.

Guides on creating custom heating programs.

Allows programming of power level for a specific time.

Displays program status during heating operations.

Shows run status for temperature-based control modes.

Displays run status for Preheat, Bake-Out, and PWHT.

Displays run status for Custom Program mode.

Displays run status for Manual Control mode.

Allows monitoring of output operating parameters.

Explains the operation of the cooler for liquid-cooled systems.

Describes the unit's power-up sequence and initial checks.

Details the output characteristics based on configuration.

Outlines regular maintenance tasks and schedules.

Instructions for cleaning the internal components.

Explains symbols used for safety during servicing.

Details hazards specific to induction heating during servicing.

Explains additional symbols for specific operational contexts.

Lists key safety standards and their sources.

Lists California's Proposition 65 warnings for chemicals.

Discusses electromagnetic field considerations in induction heating.

Describes the indicators on the operator interface.

Explains system limit conditions and how to respond.

Lists limit condition codes and their additional information.

Details system fault conditions and initial responses.

Lists fault condition codes and their additional information.

Accessing and interpreting system diagnostic screens.

Procedure for safely accessing and checking capacitor voltage.

Illustrates the electrical circuitry of the ProHeat 35 unit.

Lists parts for the unit's outer casing and panels.

Lists parts associated with the front panel assembly.

Lists parts associated with the rear panel assembly.

Lists parts found on the base assembly.

Lists parts for the top windtunnel assembly.

Lists components of the capacitor assembly.

Lists parts for the right windtunnel assembly.

Lists parts for the right windtunnel assembly (400V model).

Lists parts for the left windtunnel assembly.

Continues listing parts for the left windtunnel assembly.

Lists parts for the hermaphroditic blank plug assembly.

Lists items not covered by the Miller True Blue® warranty.