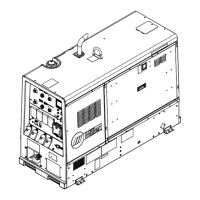

How to fix Thermocouple #4 Open (L04) limit condition on Miller ProHeat 35 OM-222 166F Welding System?

- PPhillip HoustonSep 10, 2025

To address the Thermocouple #4 Open (L04) limit condition on your Miller Welding System, check the temperature sensor for any opens and repair if needed. Alternatively, switch to a backup temperature sensor.