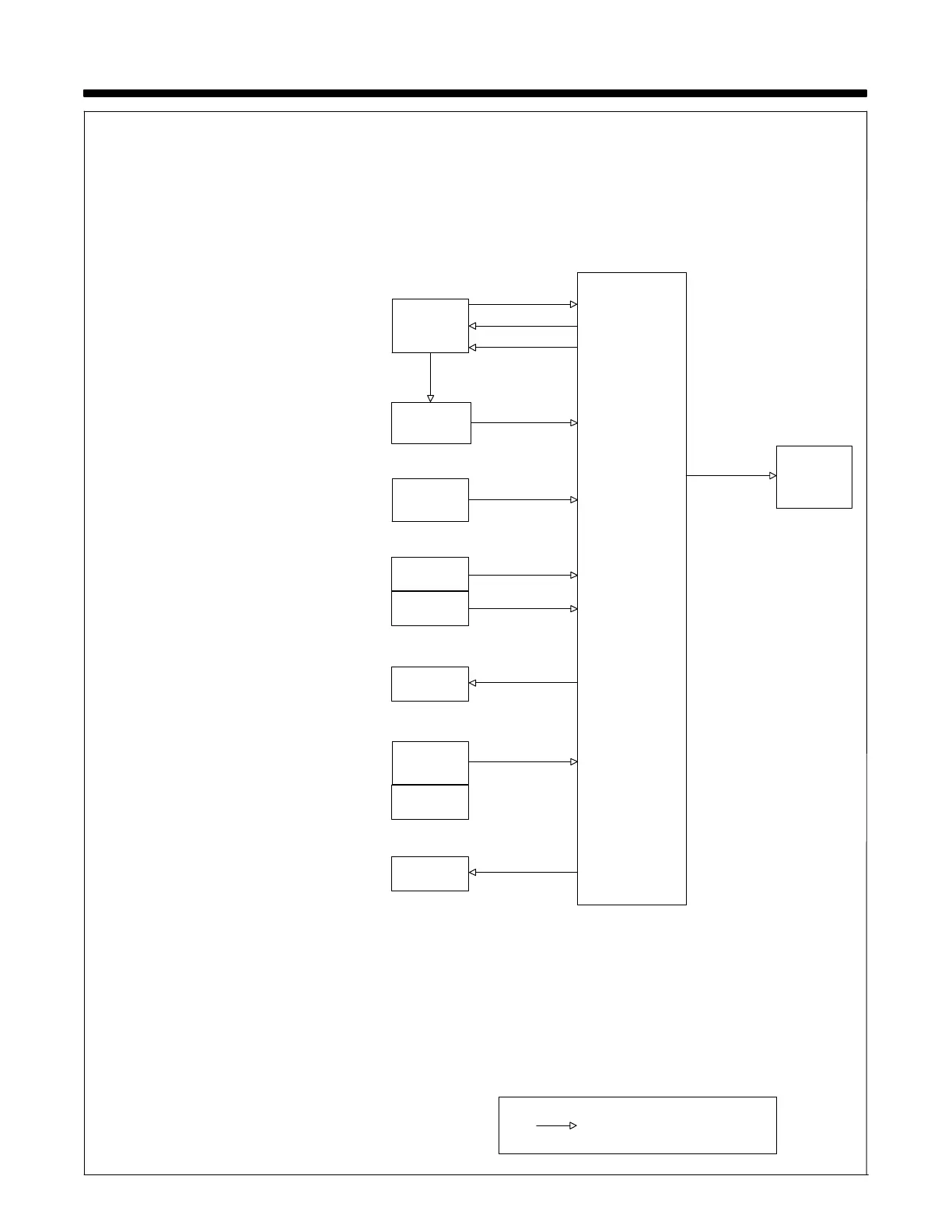

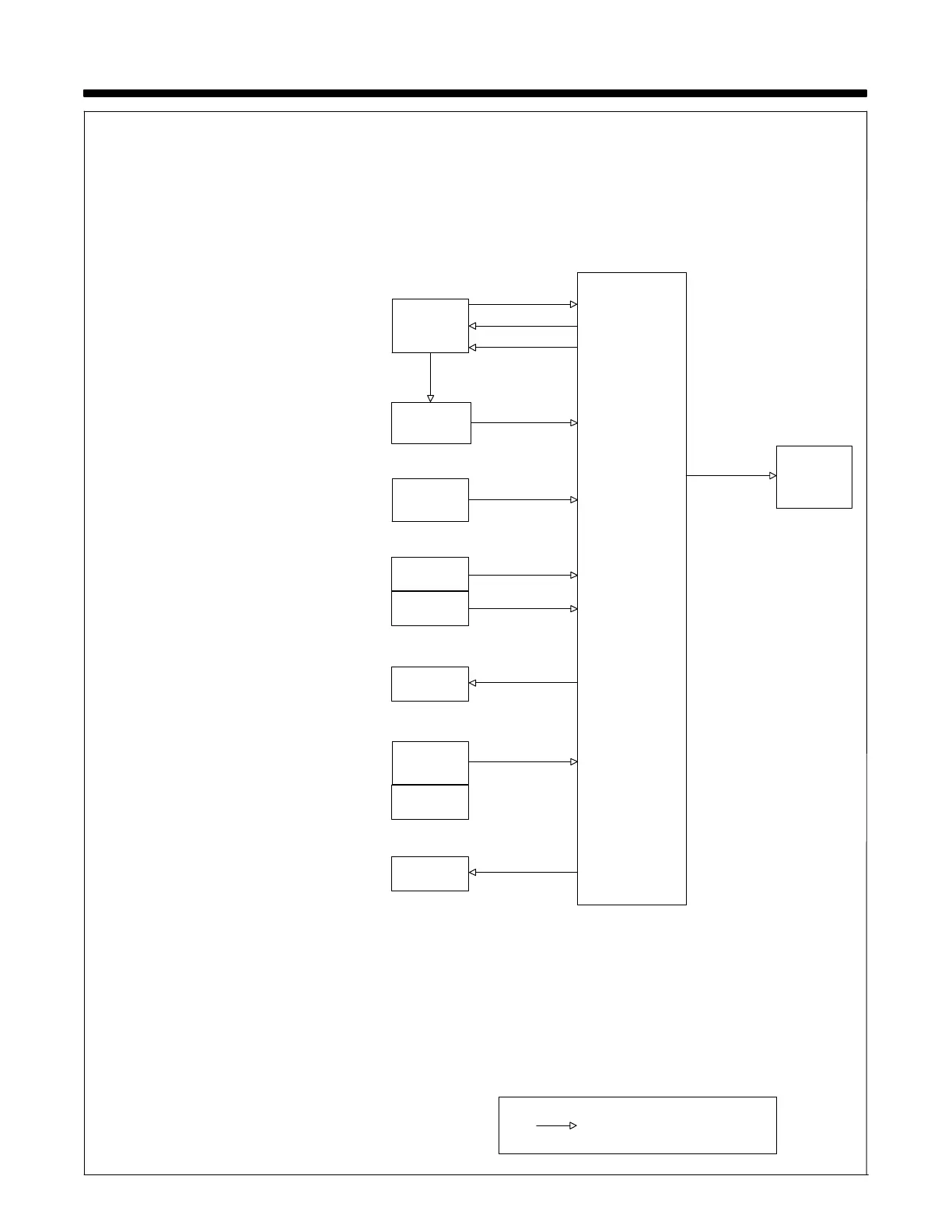

TM-273245 Page 28 S-74 MPa Plus

SECTION 8 − THEORY OF OPERATION

114−Pin Plug PLG12

Provides 24 volts AC input power from welding

power source, contactor control, voltage feedback,

current feedback, wfs (wirefeed speed) feedback,

and voltage control when used with a constant

voltage (CV) welding power source.

2 Power Switch S1

Provides On/Off control of 24 volts AC to wire feeder.

3 Gun Trigger Receptacle RC21

Connect gun trigger circuit to wire feeder. Gun trig-

ger circuit is isolated from the rest of the circuitry in

the feeder.

4 Jog/Purge Switch S2

• Jog − Permits jogging of wire drive motors

without energizing the weld circuit or gas valve.

• Purge − Energizes gas valves GS1 without en-

ergizing the weld circuit or wire drive motors.

5 Wire Drive Motor M1

Feeds wire at a speed set by wire speed control R1.

Motor speed is regulated by motor board PC1.

6 Tachometer Pickup Board PC8

Converts motor RPM to a pulsed feedback signal

used by motor board PC1 to regulate speed of wire

drive motor M1. 60 pulses are generated for every

revolution of drive motor armature.

7 Gas Valve GS1

24 volt AC valve provides shielding gas during the

weld cycle.

8 Motor Board PC1

• Controls wire speed by changing the pulse width

modulation

signal (wider or narrower pulses mean-

ing more or less voltage to motor) after comparing

motor speed feedback signals to wire speed com-

mand.

• Generates wfs command signal to send to

power supply.

• Motor speed is regulated using the tachometer

feedback signal.

• Energizes gas valve.

• Energizes contactor in welding power source.

• Uses current feedback from the welding power

source, through the 14−pin plug PLG12, to switch

feeder out of run−in. Run−in wire speed is a percent-

age of the weld wire feed speed.

• Converts voltage feedback signal, from welding

power source through 14−pin plug PLG12, from an

analog to digital signal to display on user interface

board PC2.

9 User Interface Board PC2

Displays wire speed, arc voltage, and help mes-

sages. The analog signals, of wire speed and arc

voltage, are converted to a digital signal by motor

board PC1. Motor board PC1 communicates with di-

gital meter board PC2 using serial communication.

Motor

Board

PC1

8

5

14-Pin Plug

PLG12

1

3

Serial

Communication

User

Interface

Board

PC2

9

Voltage Control

Contactor Control

Voltage & Current

Feedback

Power Switch

S1

24VAC

2

Gun Trigger

Receptacle

RC21

Purge Switch

S2

Jog Switch

S2

4

Tachometer

Feedback

PC8

6

Gas Valve

GS1

AC Or DC Control Circuits

7

Drive Motor

M1

PC8

Loading...

Loading...