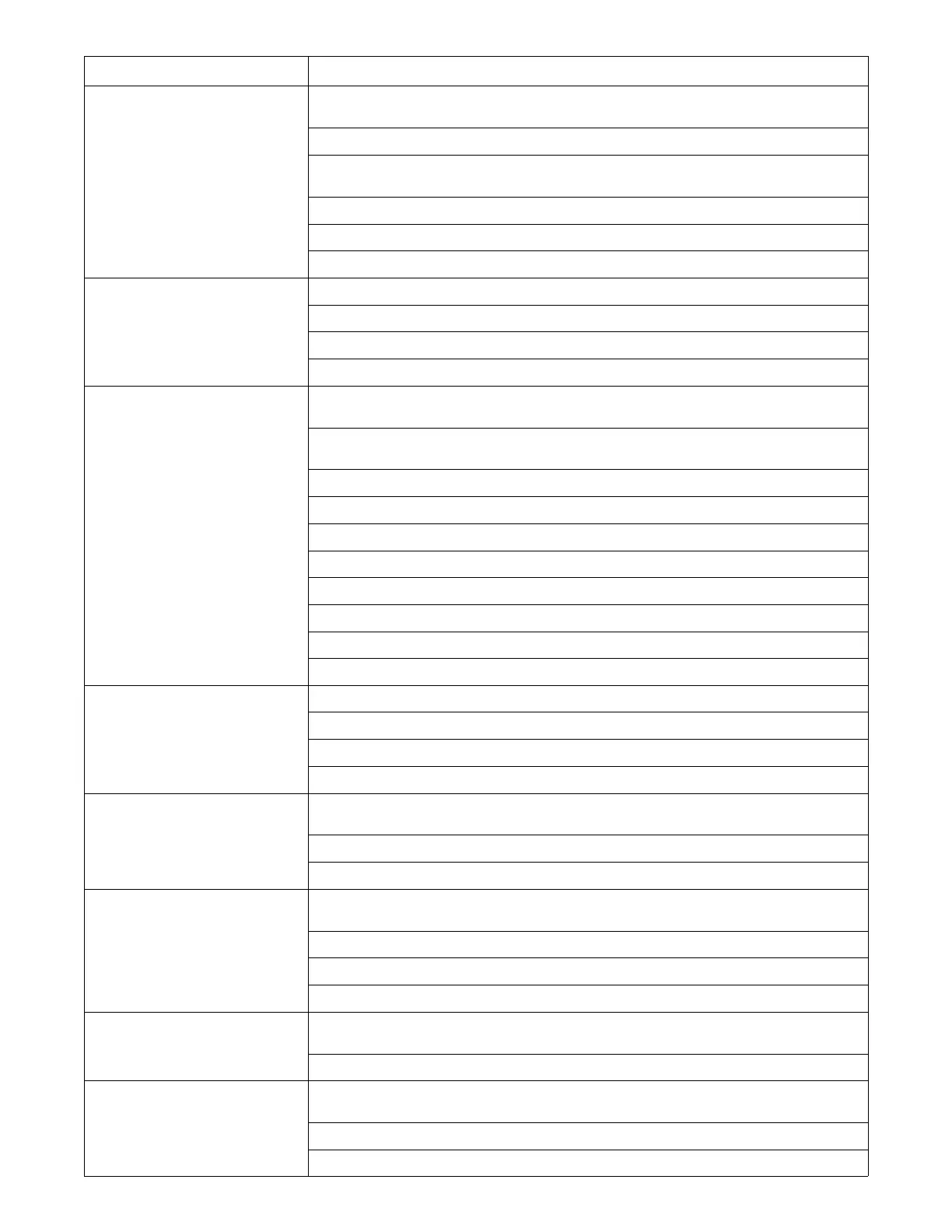

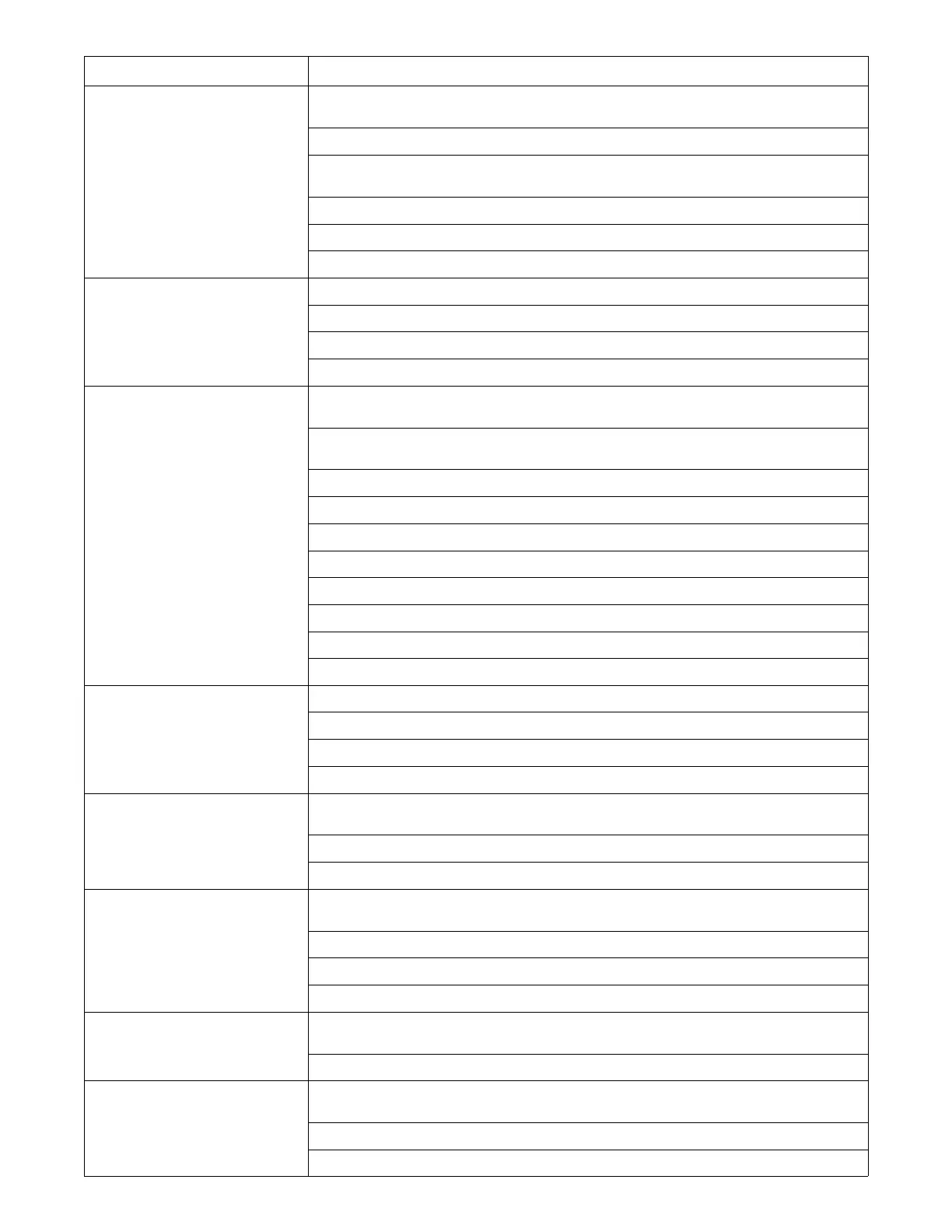

TM-273245 Page 30 S-74 MPa Plus

Trouble Remedy

Wire does not feed. Electrode wire is en-

ergized, and shielding gas flows.

Check settings for preflow, run-in, and start parameters, and adjust if necessary (See sections 7-1 & 7-3).

Check drive roll tension, and adjust if necessary (see Section 4-7).

Contact tip or liner too small for wire being used. Welding wire has pinned to the tip of the gun. Inspect

and replace if necessary.

Remove weld spatter ball or wire piece in drive roll gears (gears jammed).

Check wire drive motor M1, and replace if necessary.

Check motor board PC1 and connections, and replace if necessary (see Section 9-4).

Excessive wire shaving at push-pull. Check tension settings (see section 4-7).

Check tension settings in push-pull gun (refer to push-pull gun manual).

Verify pressure blocking clips are in correct position (see section 4-6).

Verify that nylon guides are used with aluminum wire.

Wire feeds erratically or stops while

welding.

Check gun trigger connection.

Check continuity of gun trigger switch and leads. Repair or replace welding gun. See gun Owner’s

Manual.

Clean or replace dirty or worn drive rolls (see Section 10).

Clean or replace dirty or worn drive rolls in push-pull gun (refer to push-pull gun manual).

Change to correct size and type drive roll (see Section 4-7).

Readjust drive roll pressure (see Section 4-7).

Readjust hub tension (see Section 4-7).

Check wire drive motor brushes.

Check alignment of encoder disc on tachometer board PC51 (see Section 9-13).

Check motor board PC1 and connections, and replace if necessary (see Section 9-4).

Limited wire speed control. Check push-pull gun wire speed potentiometer and control cable, and replace if necessary.

Check trigger filter board PC8 RC18, and replace if necessary (see Section 9-11).

Check tachometer board PC51 for correct feedback, and replace if necessary (see Section 9-13).

Check motor board PC1 and connections, and replace if necessary (see Section 9-4).

Wire Feed Speed Meter display does not

match actual wire feed speed.

Verify correct power source has been selected (see section 5-11).

Clean and check alignment of encoder disc on tachometer board PC51 (see Section 9-13).

Check tachometer board PC51 and connections, and replace if necessary (see Section 9-13).

Electrode wire is not energized, but wire

feeds and shielding gas flows.

Check extension cord and 14 pin plug connections. If secure, check cord for continuity and repair or

replace if necessary.

Check 14-pin filter board and connections, and replace if necessary (see Section 9-10).

Check motor board PC1 and connections, and replace if necessary (see Section 9-4).

See Troubleshooting Section in welding power source Technical Manual.

Unit does not switch out of Run-In

Speed.

Check extension cord and 14-pin plug connections. If secure, check cord for continuity and repair or

replace if necessary.

Check 14-pin filter board and connections, and replace if necessary (see Section 9-10).

Shielding gas does not flow when Purge

switch is pressed.

Clean filter screen in valve.

Check continuity of Purge switch S2, and replace if necessary.

Clear blockage in welding gun.

Loading...

Loading...