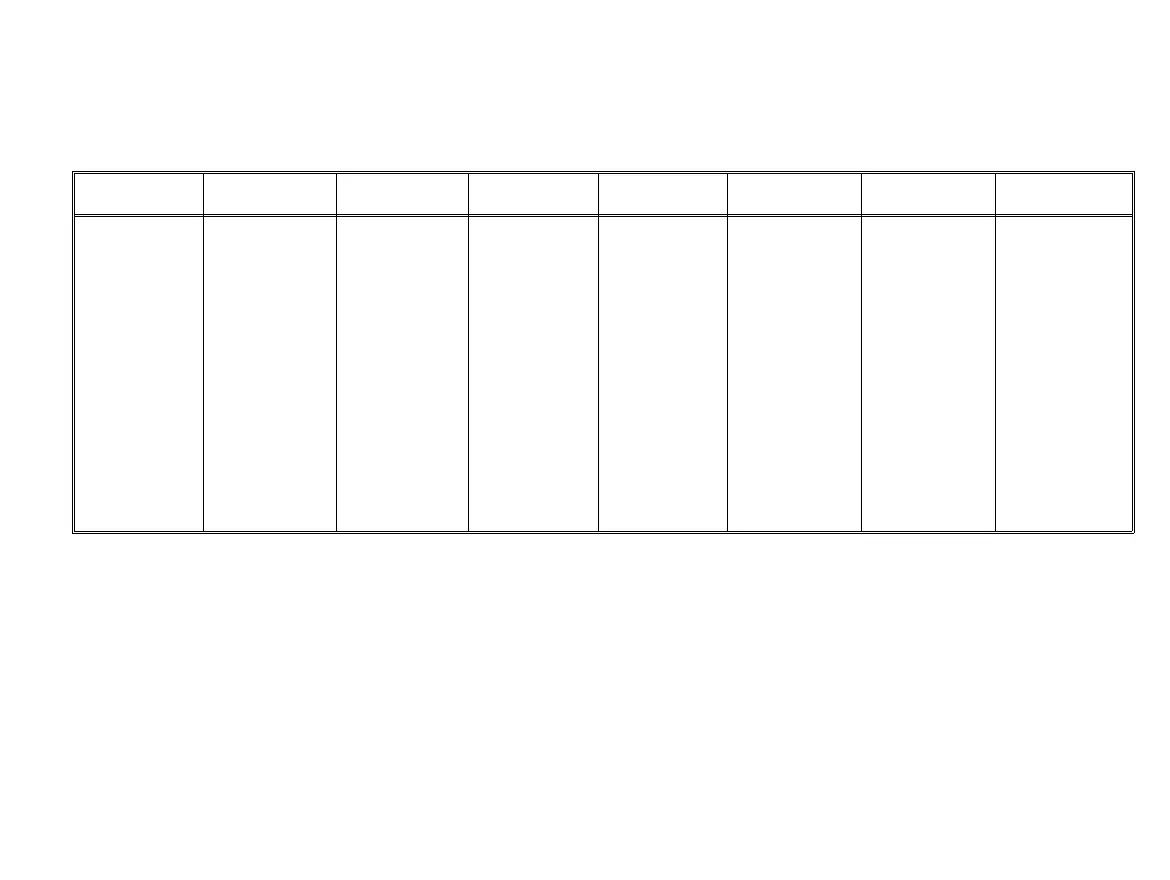

General Relays Pump Control Vol. & Disp.

Conversion

OCM Totalizer Custom Filter

P-1 units P-8 1 function

P-23 submers. P-34 tank P-40 primary P-51 OCM sim. P-60 full P-68 fill damp

P-2 mode P-9 1 on

P-24 1 hrs. P-35 dim. A P-41 time P-52 factor P-61 empty P-69 empty damp

P-3 empty dist. P-10 1 off

P-25 2 hrs. P-36 dim. L P-42 expon. P-53 decimal P-62 offset P-70 rate disp.

P-4 span

P-11 2 function P-26 3 hrs. P-37 convert P-43 flume dim. P-54 low tot. P-63 vel. 20 °C P-71 rate avg.

P-5 near blank P-12 2 on P-27 4 hrs. P-38 disp. offset P-44 spare P-55 high tot. P-64 vel. P-65 P-72 fuzz filter

P-6 mA out P-13 2 off P-28 5 hrs. P-39 disp. opt’n P-45 max. head P-56 remote tot. P-65 temp. P-73 agitator

P-7 decimal P-14 3 function P-29 run-on P-46 max. flow P-57 flow samp. P-66 max. temp P-74 f-s mode

P-15 3 on P-30 run-on P-47 auto zero P-58 flow samp. P-67 min. temp P-75 f-s timer

P-16 3 off P-31 spare P-48 cutoff P-59 time samp.

P-17 4 function P-32 DLD mA out P-49 decimal

P-18 4 on P-33 totaling P-50 mA out

P-19 4 off

P-20 5 function

P-21 5 on

P-22 5 off

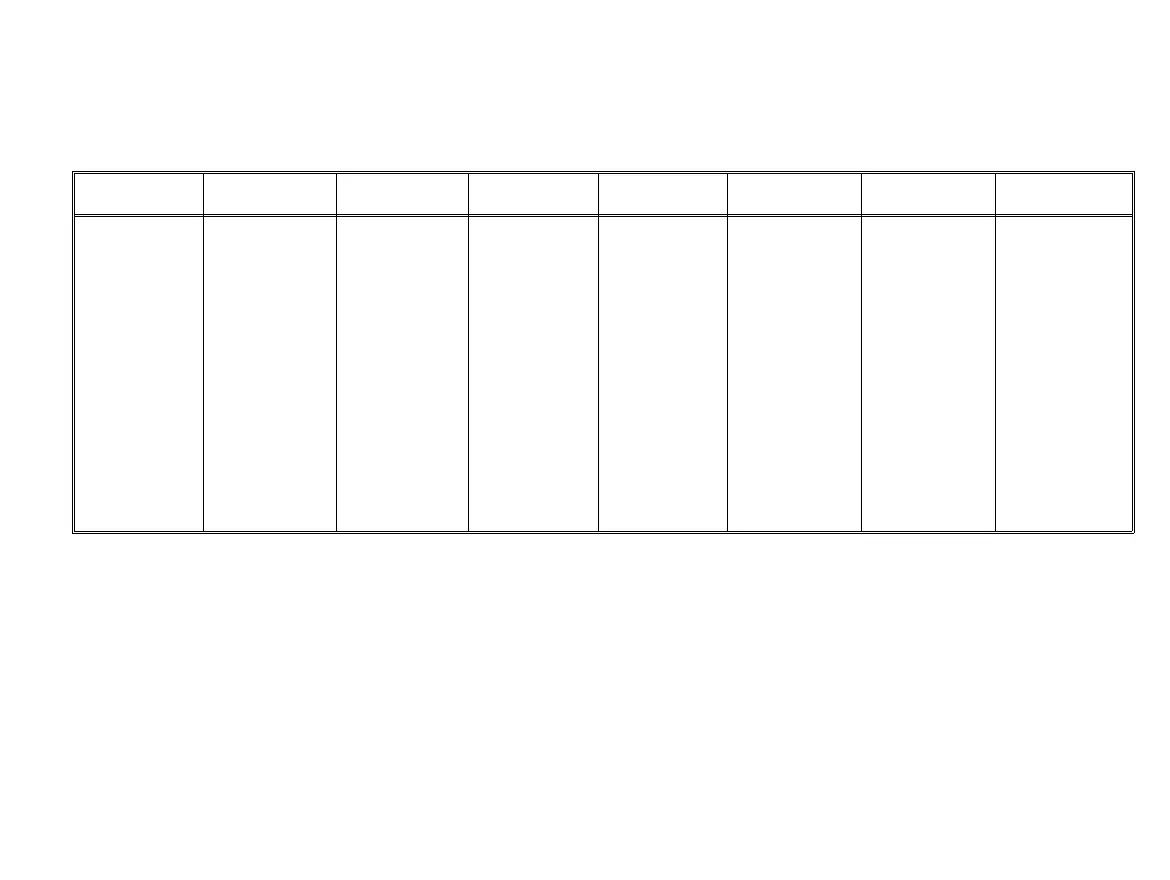

PUMP CONTROL

APPLICATION PARAMETERS

P-#

required parameters

P-# optional parameters

P-# parameters not required

Loading...

Loading...