CHAPTER 1 - SAFETY

1

2

3

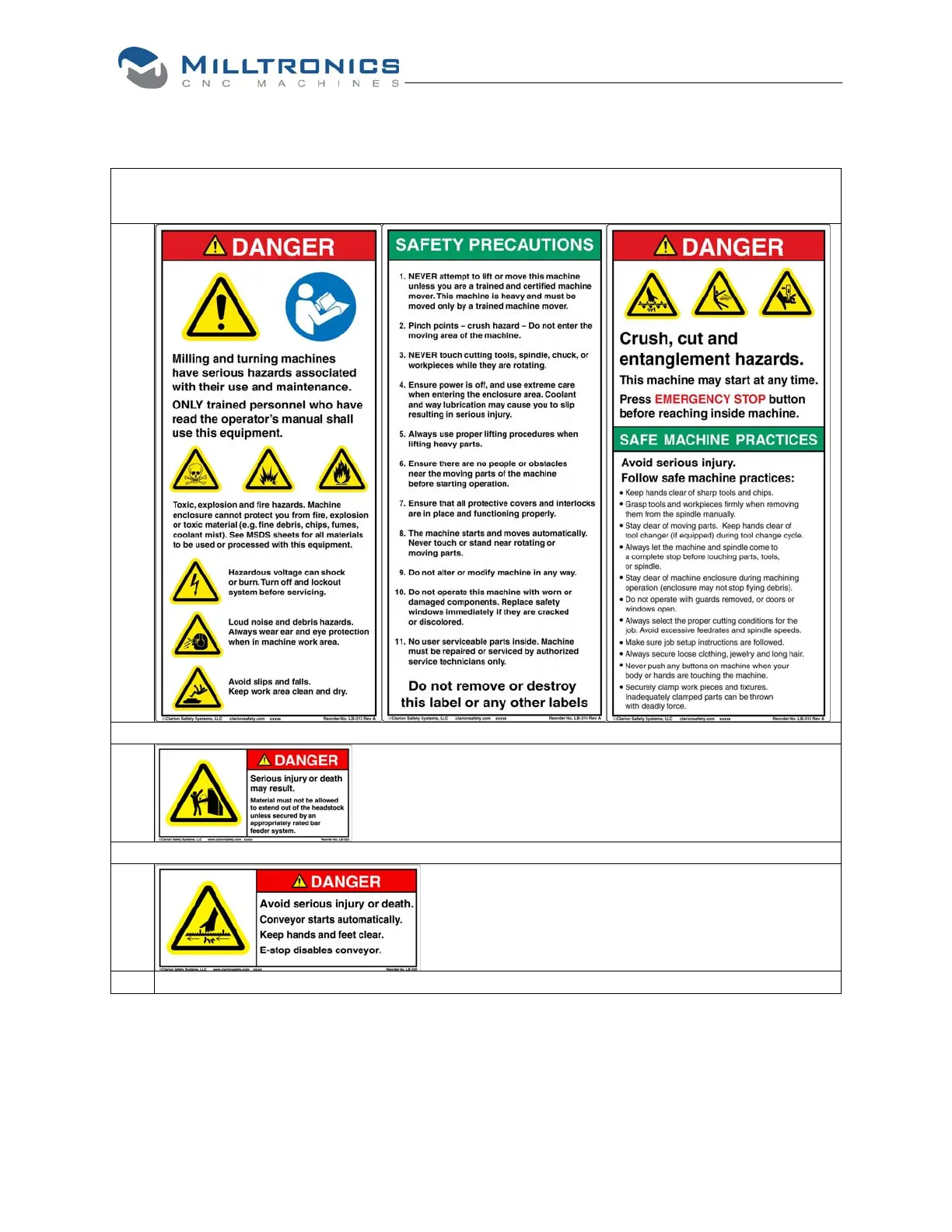

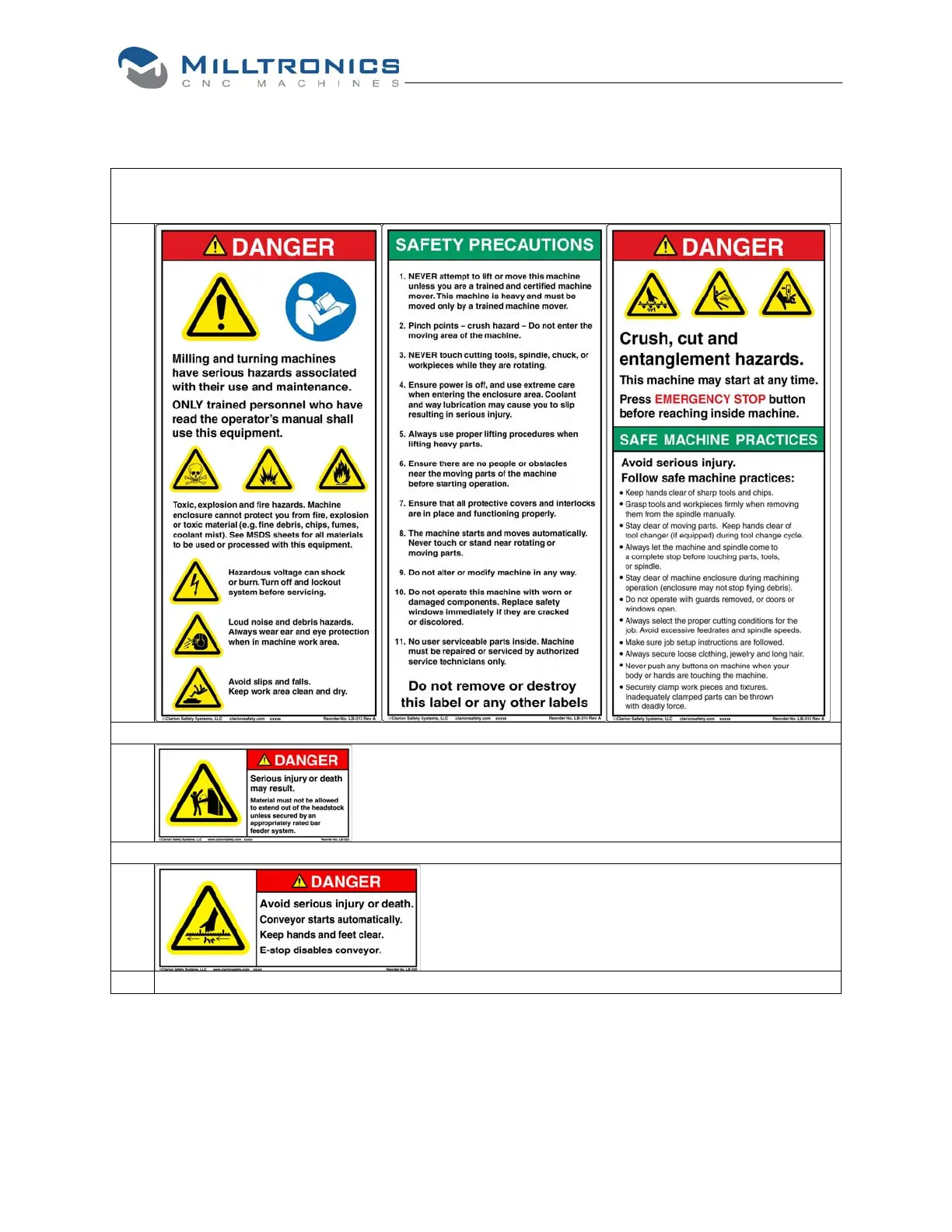

Read and understand all Safety, Operation, and Maintenance labels affixed to

the machine to ensure safet

and reliabilit

.

Located at headstock end near spindle

through hole.

Located around hazard areas on models

equipped with chip conveyor.

9

Loading...

Loading...