Pellerin Milnor Corporation 15

3.1.1.3 Components that Become Worn

BNUUUH01.R12 0000399389 A.5 A.26 A.23 11/16/21 11:00 AM Released

Examine these items. Tighten or replace the item if necessary, to prevent shutdowns and un-

satisfactory performance. Speak to your dealer for replacement parts.

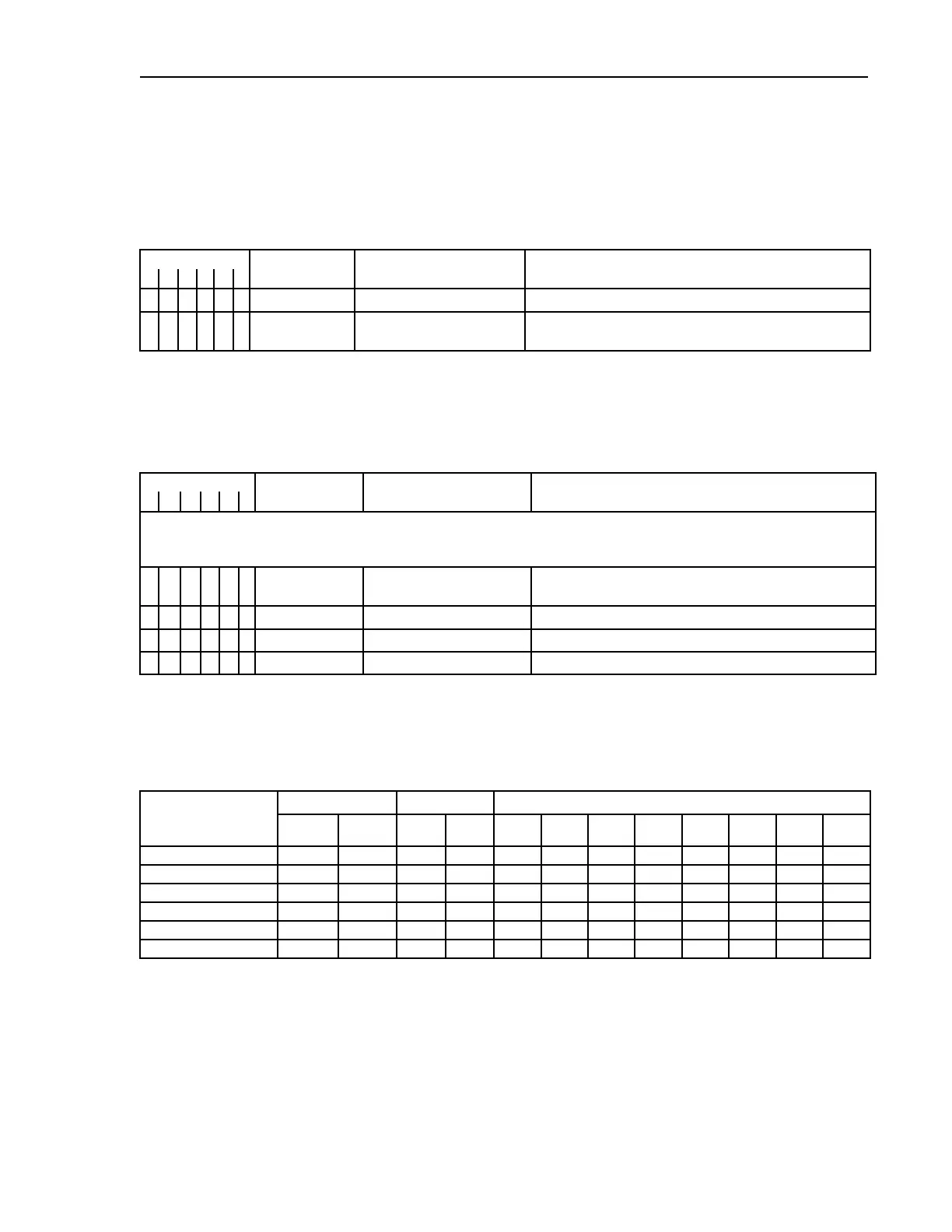

Table 3. Components that Become Worn

Mark

Do this each

Component

More Data

1 2

3

4

5

6

x

200 hours drive belts and pulleys See Section 3.2.1 , page 22

x

200 hours tubes and hoses (non-

hydraulic)

Examine hoses and hose connections for leaks.

3.1.1.4 Bearings and Bushings

BNUUUH01.R13 0000399388 A.5 A.26 11/16/21 11:04 AM Released

Unless the item is sealed, apply grease to prevent damage. See the next section for motors.

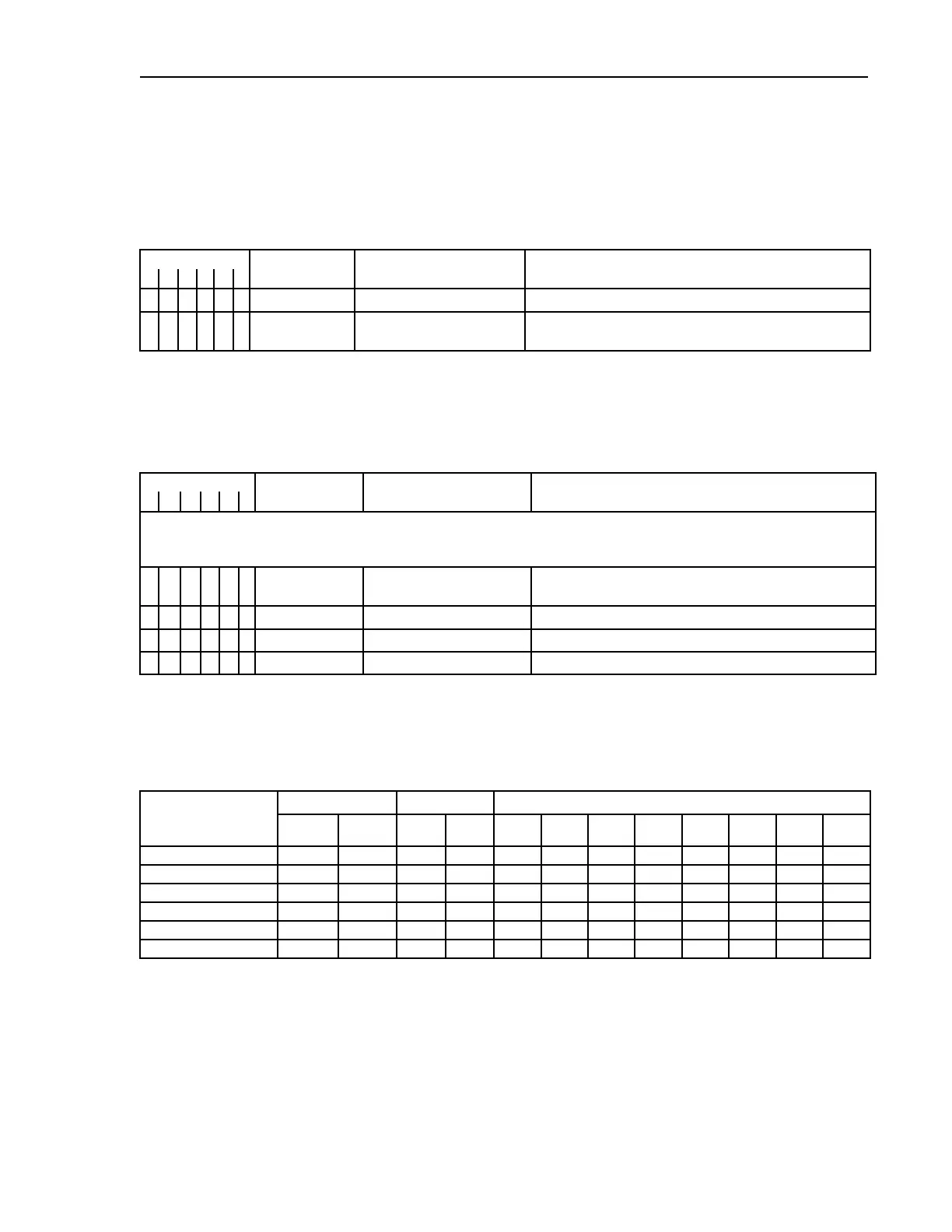

Table 4. Bearings and Bushings

Mark

Do this each

Component More Data . See also Section 3.1.3 , page 17

1 2 3 4

5 6

Grease plate 01 10025Z for bearing housing. Use this data if your machine has this grease plate. See Figure 18, page 31

and Section 3.1.5 : Procedures for Bearing Components Connected to a Grease Plate, page 18. It is necessary to remove a

side panel on some models, to access this grease plate.

x

200 hours seal Add 0.06 oz. (1.8 mL) of grease EPLF2 (Table 8, page

17)

x

200 hours rear bearing Add 0.12 oz. (3.6 mL) of grease EPLF2

x

200 hours front bearing Add 0.12 oz. (3.6 mL) of grease EPLF2

x

600 hours motor and pump bearings See Section 3.1.6 : Procedures for Motors, page 19

3.1.1.5 Motor Grease Schedule

BNUUUH01.R15 0000399408 A.5 A.26 10/21/21 10:14 AM Released

Use the data in Table 9: Motor Grease Intervals and Quantities, page 21 to complete this table.

Table 5. Motor Grease Schedule

Motor Identifica-

tion (example: main

drive)

Interval

Quantity

Dates When Grease is Added

Years Hours fl oz mL

.

3.1.1.6 Mechanisms and Settings

BNUUUH01.R14 0000399409 A.5 A.26 A.11 11/16/21 11:14 AM Released

Make sure mechanisms are serviceable and settings are correct to prevent unsatisfactory

performance.

Routine Maintenance

Loading...

Loading...