APPENDICES

APP − 13

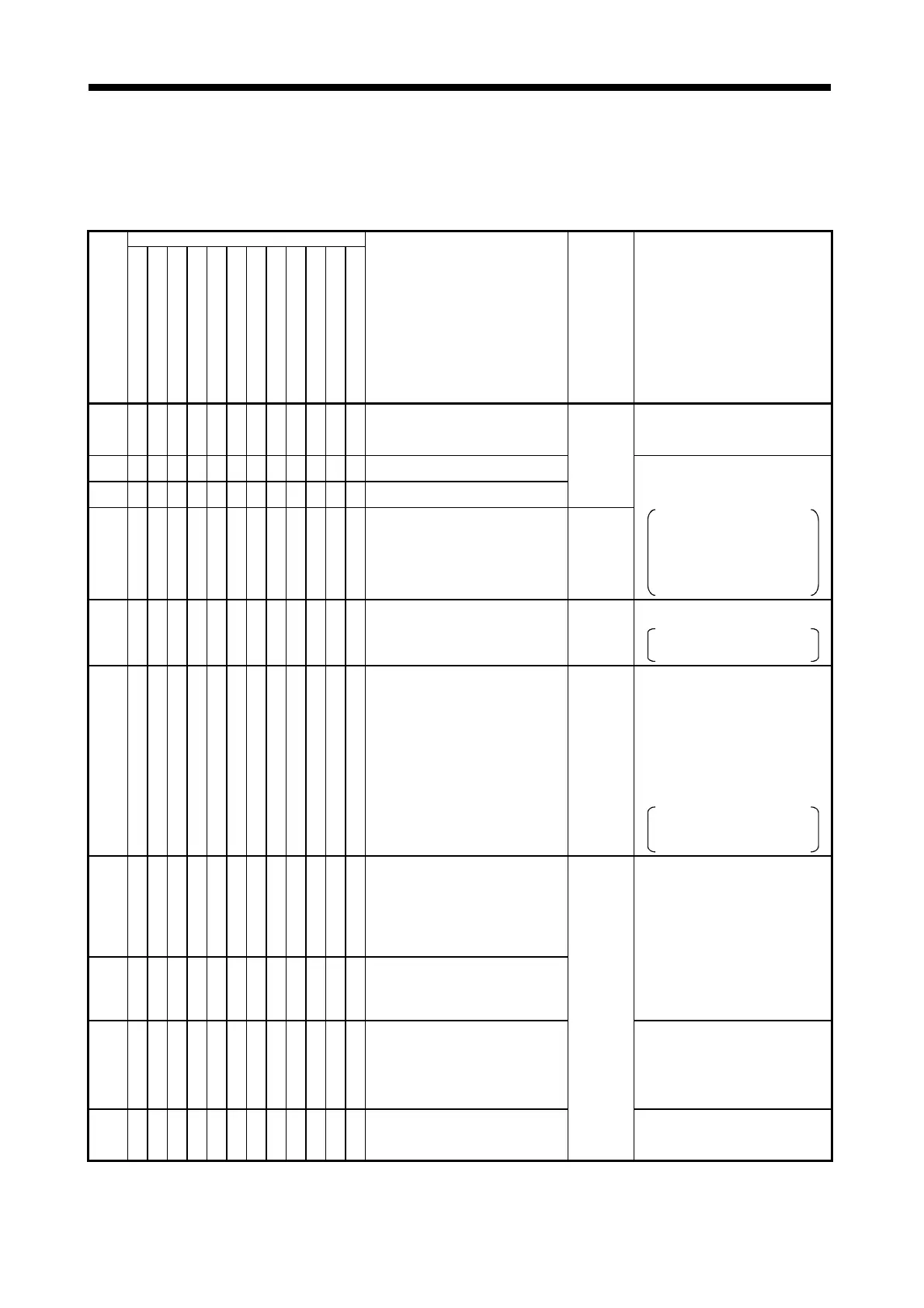

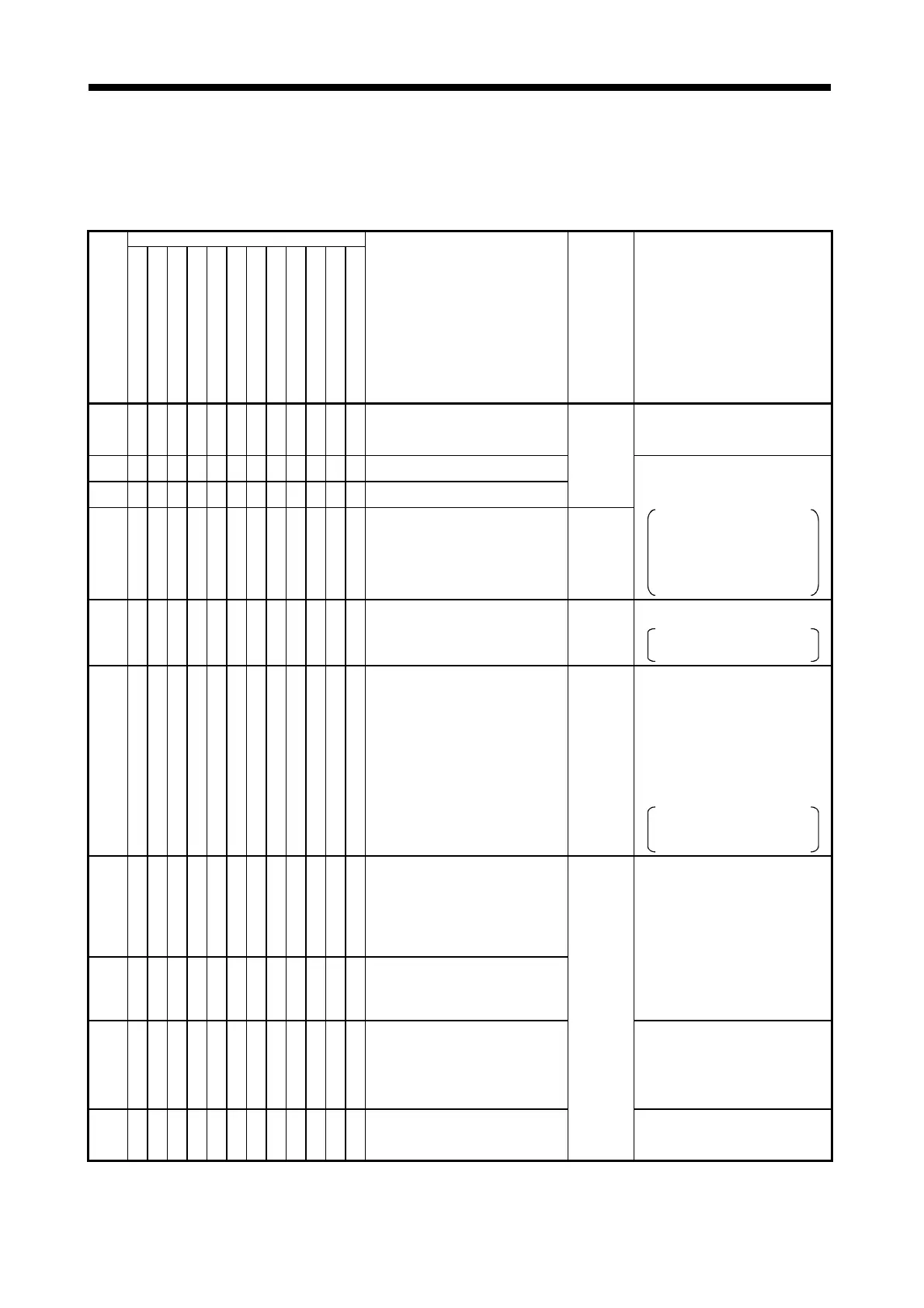

(3) Positioning control errors (200 to 299)

The errors shown in this section are those detected during positioning control.

Error codes, causes and corrective actions are shown in Table 2.5.

Table 2.5 Positioning Control Start-Up Error List (200 to 299)

Control Mode

Error

Code

Positioning

Fixed-Pitch Feed

Speed

Speed/Position Switching

Speed Switching

Constant-Speed

JOG

Manual Pulse Generator

Zeroing

Position Follow-Up Control

OSC

Error Cause

Error

Processing

Corrective Action

200 !!!!!!!! !!

• The PLC ready flag (M2000) was turned

OFF while positioning was being started in

response to a start request issued by a

sequence program.

• Turn the PLC ready flag (M2000) ON after

all axes have stopped.

201 !

• The PLC ready flag (M2000) was turned

OFF during a zeroing operation.

202 !

• The stop command (M3200+20n) has been

turned ON during a zeroing operation.

Axis motion

decelerates

to a stop.

203 !

• The rapid stop command (M3201+20n) has

been turned ON during a zeroing operation.

Axis motion

stops

immediately.,

• After turning the PLC ready flag (M2000)

ON or turning the stop command

(M3200+20n) or rapid stop command

(M3201+20n) OFF, re-attempt zeroing.

In the case of a proximity dog type

zeroing, use JOG operation or

positioning operation to return the axis

to the point before the proximity dog

signal was output, and re-attempt

zeroing.

204 !!!!!!!!!!!

• The PLC ready flag (M2000) was turned

back ON during deceleration initiated by

turning OFF the PLC ready flag (M2000).

No

processing

• Turn the PLC ready flag (M2000) ON after

all axes have stopped.

Turning ON the PLC ready flag

(M2000) during deceleration is ignored.

206 !

• While a zeroing operation was in progress,

an emergency stop was executed in the test

mode at a peripheral device by pressing the

[Back Space] key.

Axis motion

stops

immediately.

• In the case of a proximity dog type zeroing,

use JOG operation or positioning operation

to return the axis to the point before the

proximity dog signal was output, and re-

attempt zeroing.

• If the proximity dog signal is turned OFF

when executing a count type zeroing, use

JOG operation or positioning operation to

return the axis to the point before the

proximity dog signal was output, and re-

attempt zeroing.

In the proximity dog signal is

turned ON when executing count type

zeroing, re-attempt the zeroing.

207 !!!!!

• The feed current value exceeded the stroke

limit during positioning.

In the case of circular interpolation, an error

code is stored only for axis whose feed

current value exceeded the stroke limit.

In the case of linear interpolation, error

codes are stored for all axes involved in the

interpolation.

208 !!!!

• During circular interpolation or during

simultaneous operation of multiple manual

pulse generators, the feed current value of

another axis exceeded the stroke limit value.

(For detection of other axis errors).

• Correct the stroke limit or travel value

setting so that positioning is executed

within the stroke limit.

209 !!

• An overrun has occurred because the set

travel value exceeds the deceleration

distance when a speed/position change

(CHANGE) signal is input during

speed/position switching control, or when

the proximity dog signal is input during

count type zeroing.

• Correct the speed setting so that overrun

does not occur.

• Set a travel value which will not cause an

overrun.

210 !

• During speed/position switching control, the

set travel value exceeds the stroke limit

when a speed/position switching (CHANGE)

signal is input.

Axis motion

decelerates

to a stop.

• Correct the stroke limit or travel value

setting so that positioning is executed

within the stroke limit.

Loading...

Loading...