4D68 ENGINE (E-W) -

Crankshaft, Cylinder Block and Flywheel

11A-12-8

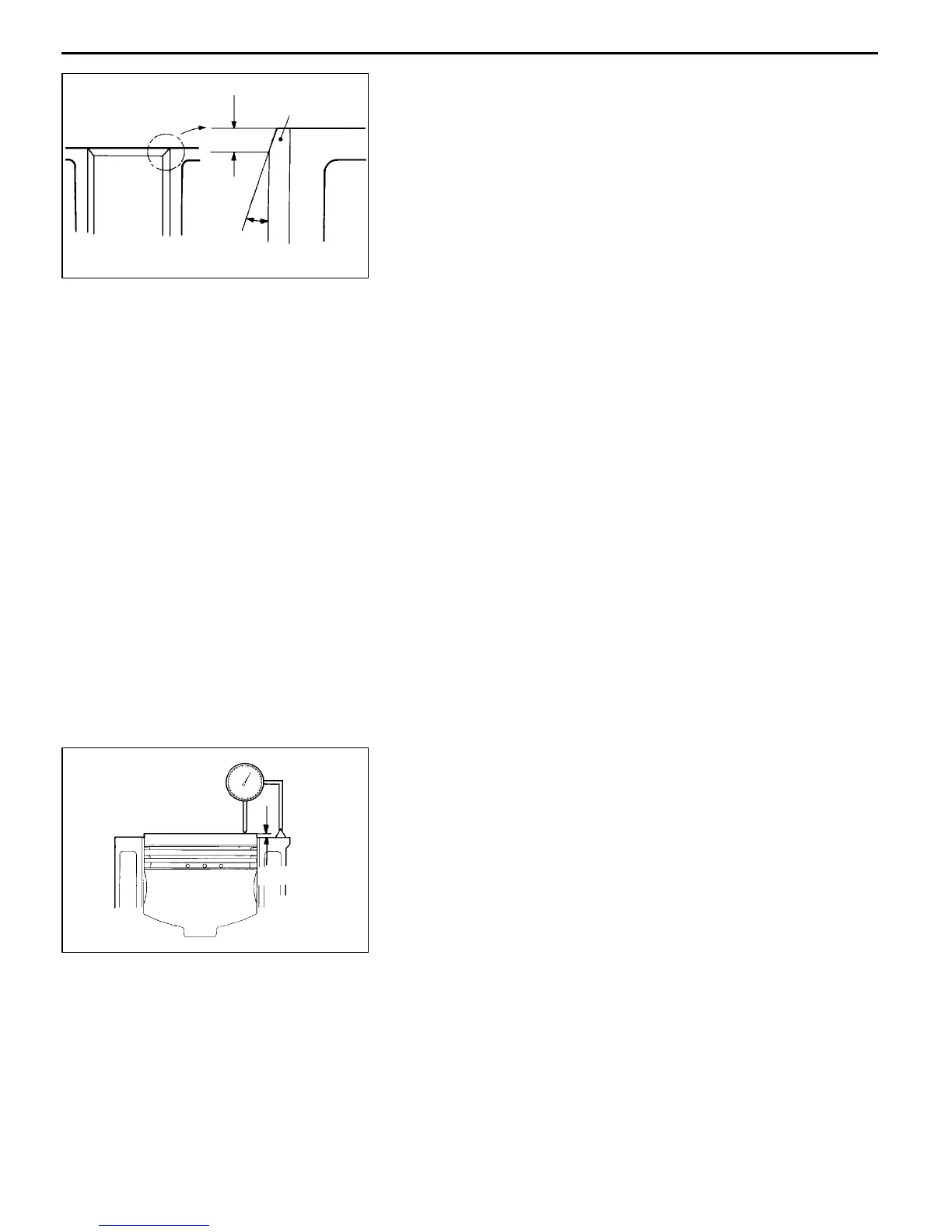

(5) Chamfer the cylinder sleeve top end as illustrated.

(6) The service cylinder sleeve has the I.D. machined to 81.5

to 81.7 mm. After installation of the sleeve, therefore,

hone the I.D. to the standard value.

Cylinder I.D.: 82.70 - 82.73 mm

Honing finished surface roughness: 2 - 4

m

Honing cross hatch angle: 15 - 25

°

Cylinder bore squareness: 0.05 mm

When boring the cylinder block sleeve hole

(1) Prepare a cylinder sleeve of 0.5 mm oversize (identification

color: red).

(2) Hone the cylinder block sleeve hole to 86.13 to 86.15

mm.

(3) Install the cylinder sleeve and finish the I.D. The installation

and machining procedures are the same as in the case

when the block sleeve hole has not been bored.

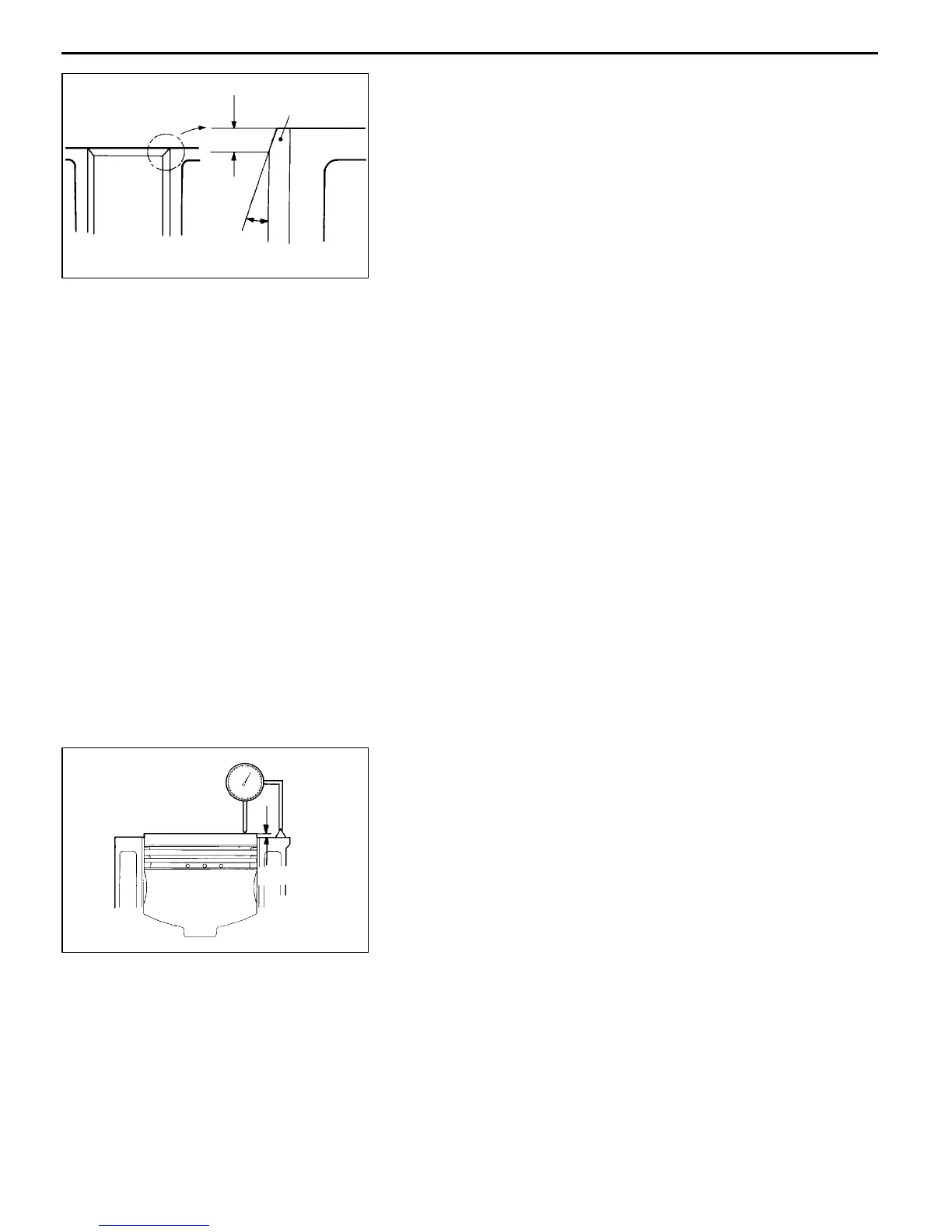

INSPECTION AFTER ASSEMBLY

(1) After assembling the crankshaft, piston, etc., check the

piston protrusion.

If the protrusion exceeds the limit, change the piston and

connecting rod in order to reduce the protrusion to within

the limit.

(2) If the protrusion still exceeds the limit after piston

reassembly, replace the cylinder block.

Limit: 0.823 mm

PWEE9609

E

Dec. 1996Mitsubishi Motors Corporation

DEN244

Cylinder sleeve

0.5 mm

30

°

DEN0798

Protrusion

Loading...

Loading...