9 - 62

MELSEC-Q

9 MAJOR POSITIONING CONTROL

Positioning data setting example

[Reference axis and interpolation axis are designated as axis 1 and axis 2,

respectively.]

The following table shows setting examples when "2-axis circular interpolation

control with sub point designation (INC circular sub)" is set in positioning data No.

1 of axis 1. (The required values are also set in positioning data No. 1 of axis 2.)

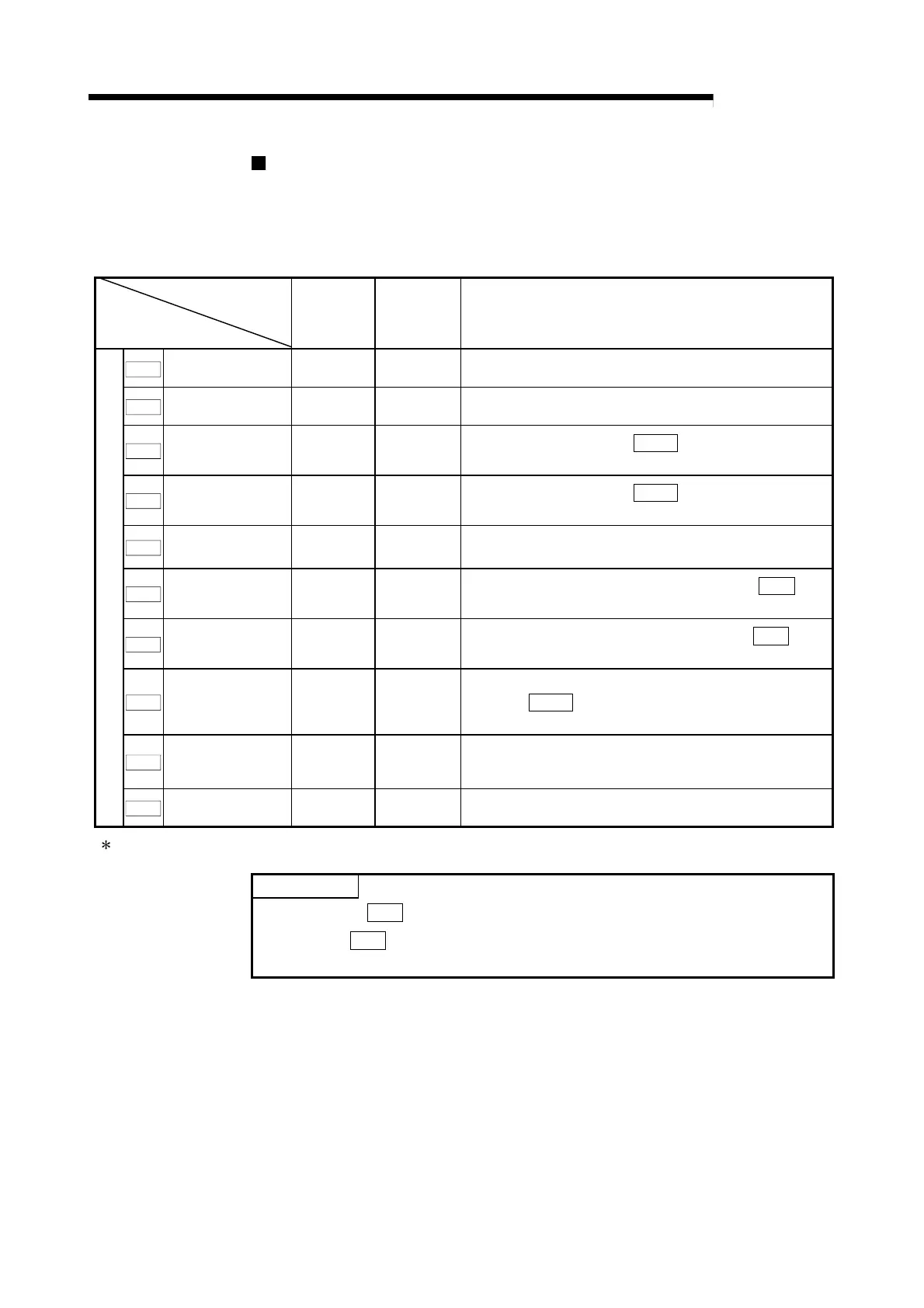

Axis

Setting item

Axis 1

(reference

axis) setting

example

Axis 2

(interpolation

axis) setting

example

Setting details

Da.1

Operation pattern

Positioning

complete

–

Set "Positioning complete" assuming the next positioning

data will not be executed.

Da.2

Control system

INC circular

sub

–

Set incremental system, 2-axis circular interpolation control

with sub point designation.

Da.3

Acceleration time

No.

1 –

Designate the value set in "

Pr.25

Acceleration time 1" as

the acceleration time at start.

Da.4

Deceleration time

No.

0 –

Designate the value set in "

Pr.10

Deceleration time 0" as

the deceleration time at deceleration.

Da.5

Axis to be

interpolated

Axis 2 –

Set the axis to be interpolated (partner axis).

If the self-axis is set, an error will occur.

Da.6

Positioning address/

movement amount

8000.0

μ

m 6000.0

μ

m

Set the movement amount. (Assuming that the "

Pr.1

Unit

setting" is set to "mm".)

Da.7

Arc address

4000.0

μ

m 3000.0

μ

m

Set the sub point address. (Assuming that the "

Pr.1

Unit

setting" is set to "mm".)

Da.8

Command speed

6000.00

mm/min

–

Set the speed during movement. (Designate the composite

speed in "

Pr.20

Interpolation speed designation

method".)

Da.9

Dwell time 500ms –

Set the time the machine dwells after the positioning stop

(pulse output stop) to the output of the positioning complete

signal.

Axis 1 Positioning data No. 1

Da.10

M code 10 –

Set this when other sub operation commands are issued in

combination with the No. 1 positioning data.

Refer to Section 5.3 "List of positioning data" for information on the setting details.

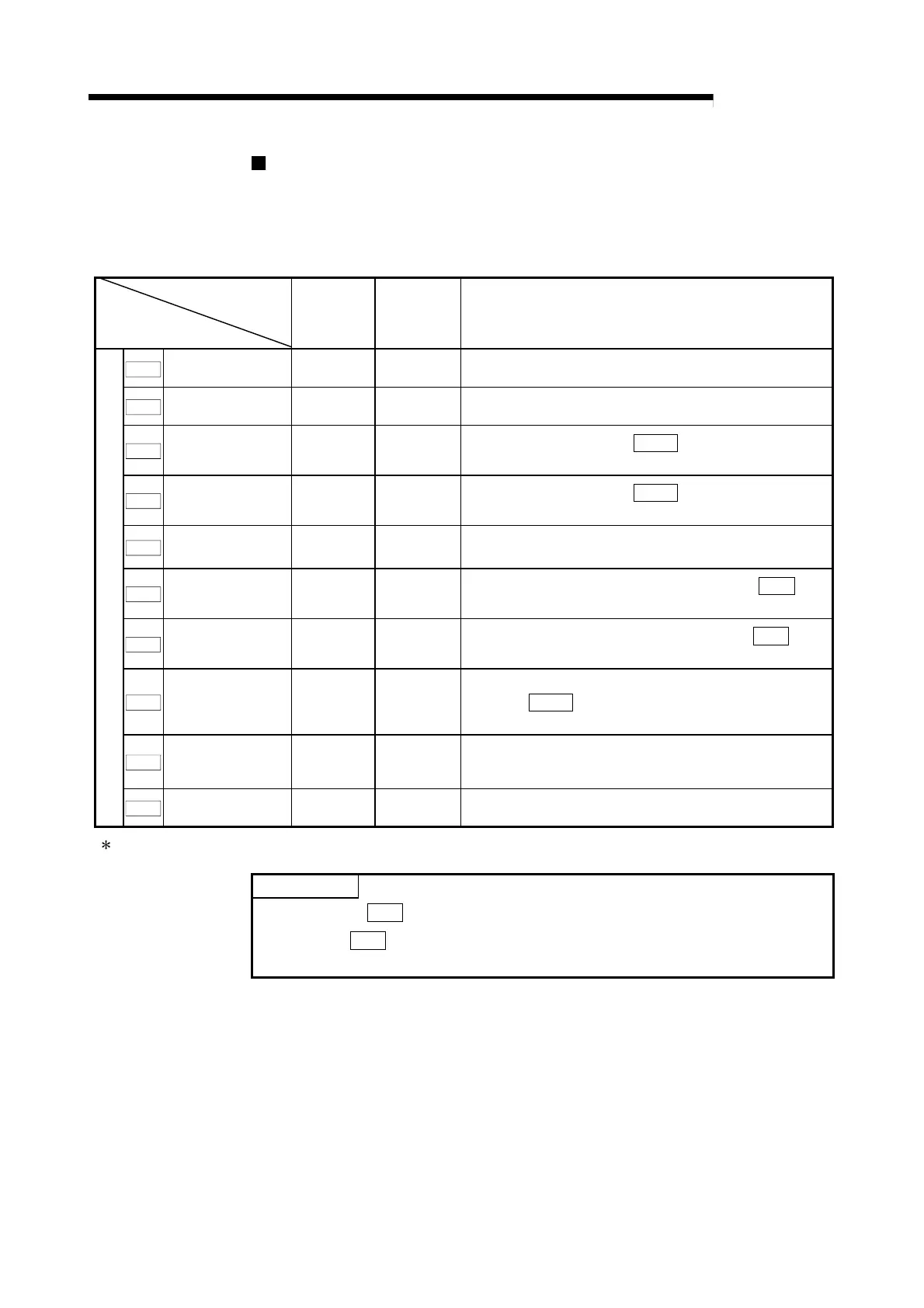

POINT

Set a value in "

Da.8

Command speed" so that the speed of each axis does not

exceed the "

Pr.8

Speed limit value". (The speed limit does not function for the

speed calculated by the QD75 during interpolation control.)

Loading...

Loading...