12 - 63

MELSEC-Q

12 CONTROL SUB FUNCTIONS

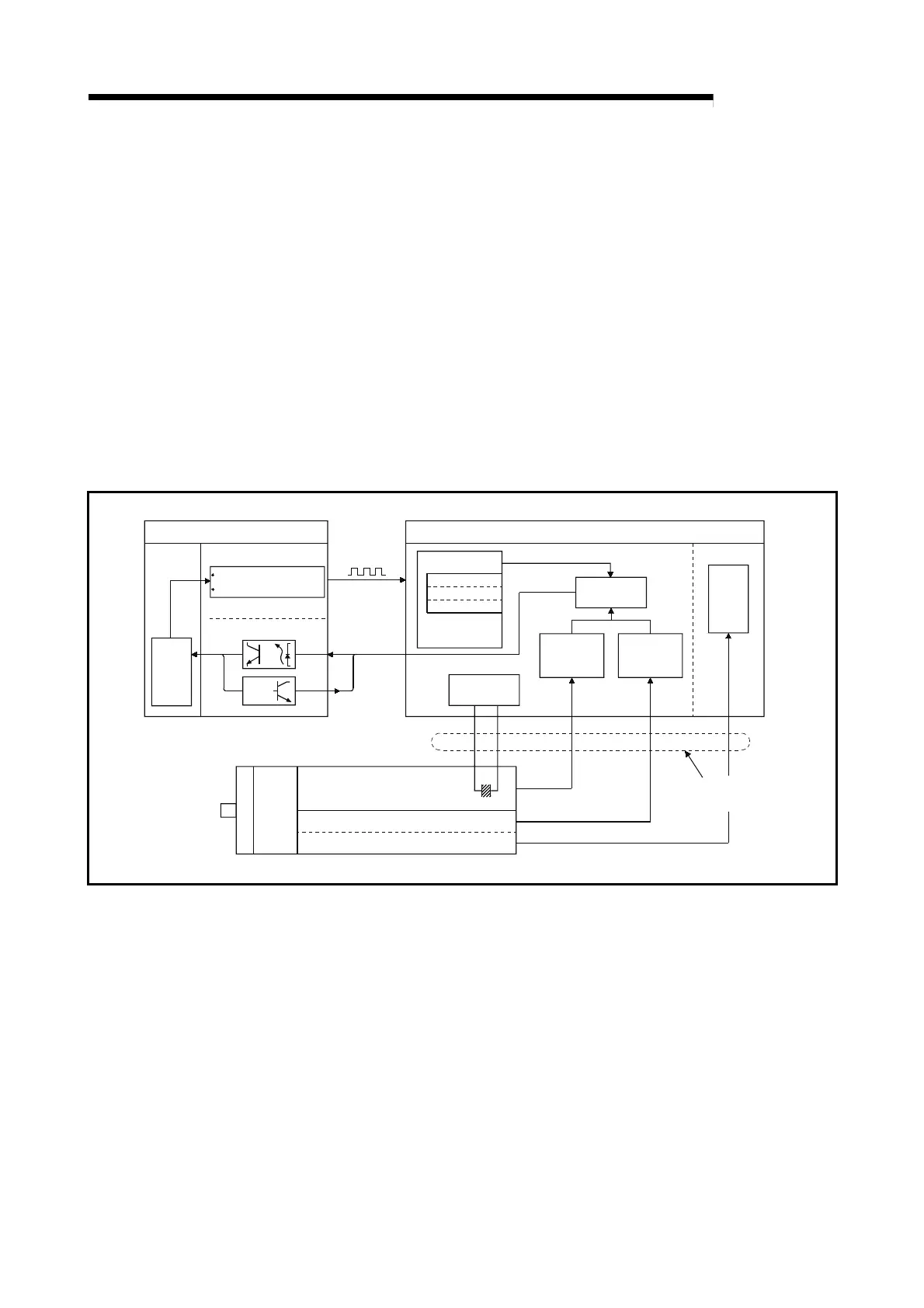

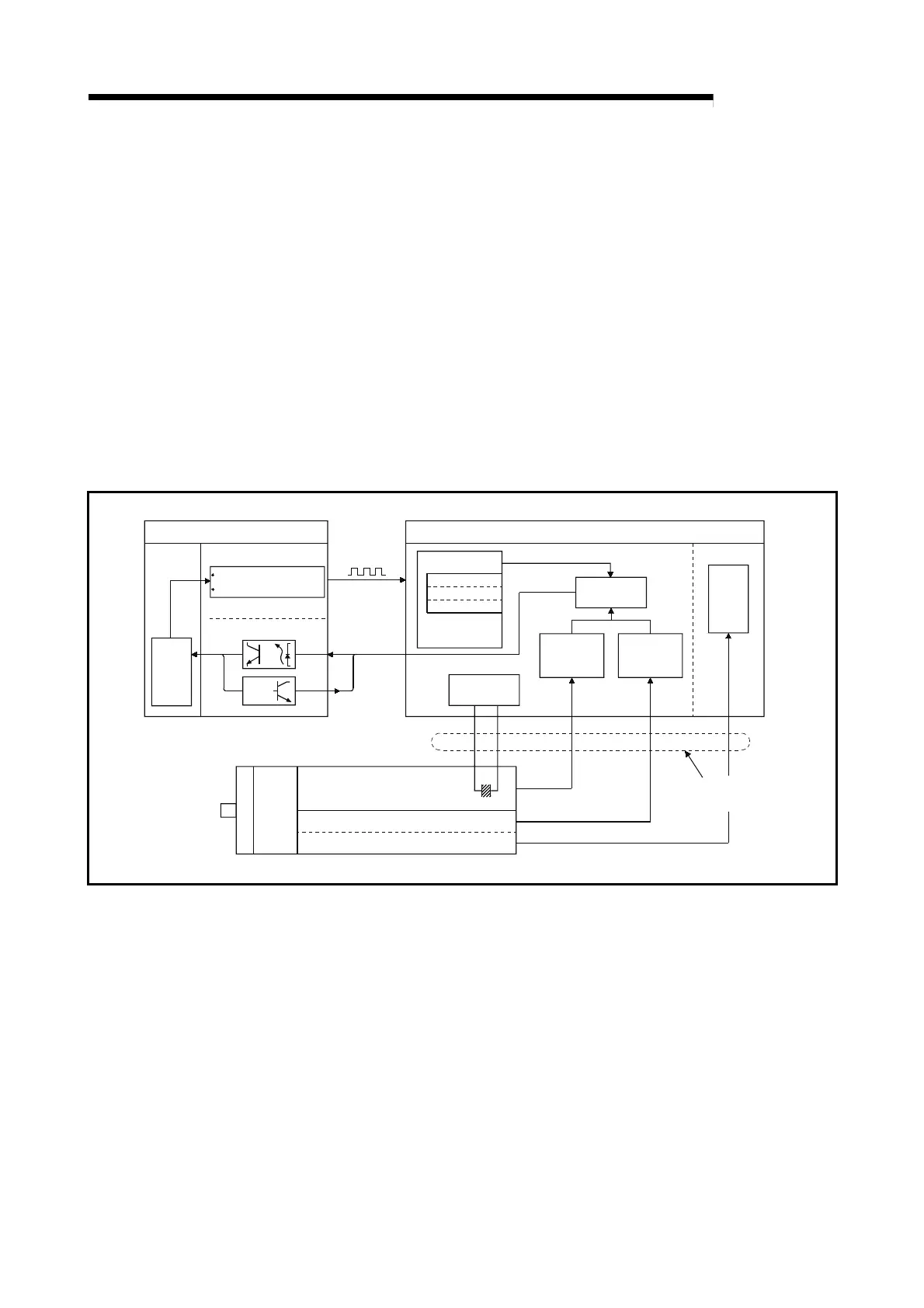

[2] Outline of absolute position detection data communication

As shown in Fig. 12.35 System block diagram, the detector comprises an

encoder for detecting its position in one rotation in addition to the A, B, Z phase

signal for position control in normal operation and a cumulative rotation counter

for detecting the number of rotations.

The absolute position detection system detects the absolute position of the

machine constantly and stores it with the backup of the battery irrespective of

whether the programmable controller system power is turned ON/OFF. Thus,

once the OP initial setting is carried out at the time of installation of the machine,

the OPR is not required even when the power is later turned ON. The restoration

can be carried out easily when an instantaneous power interruption or

emergency stop occurs.

In addition, because the absolute position data is backed up by a super

condenser built in the detector, the absolute position data will be stored for a

specified time even if the cable is disconnected or broken.

I/O module

Programmable controller system

Current feed value

Current

position

change

QD75QCPU

Output

Input

Servo amplifier

Position

control/

speed

control

Pulse train

command

OP data

Backup at

power OFF

LS0

1X0

1X

Detection of

position in one

rotation

LS

detection of

number of

rotations

Servomotor

Counter in one rotation

A.B.Z phase signal

Detector

1 pulse/rev cumulative rotation

counter

Super condenser

High-speed serial

communication

Battery

Current

position

Machine feed value

E PROM memory

2

Fig. 12.37 System block diagram

Loading...

Loading...