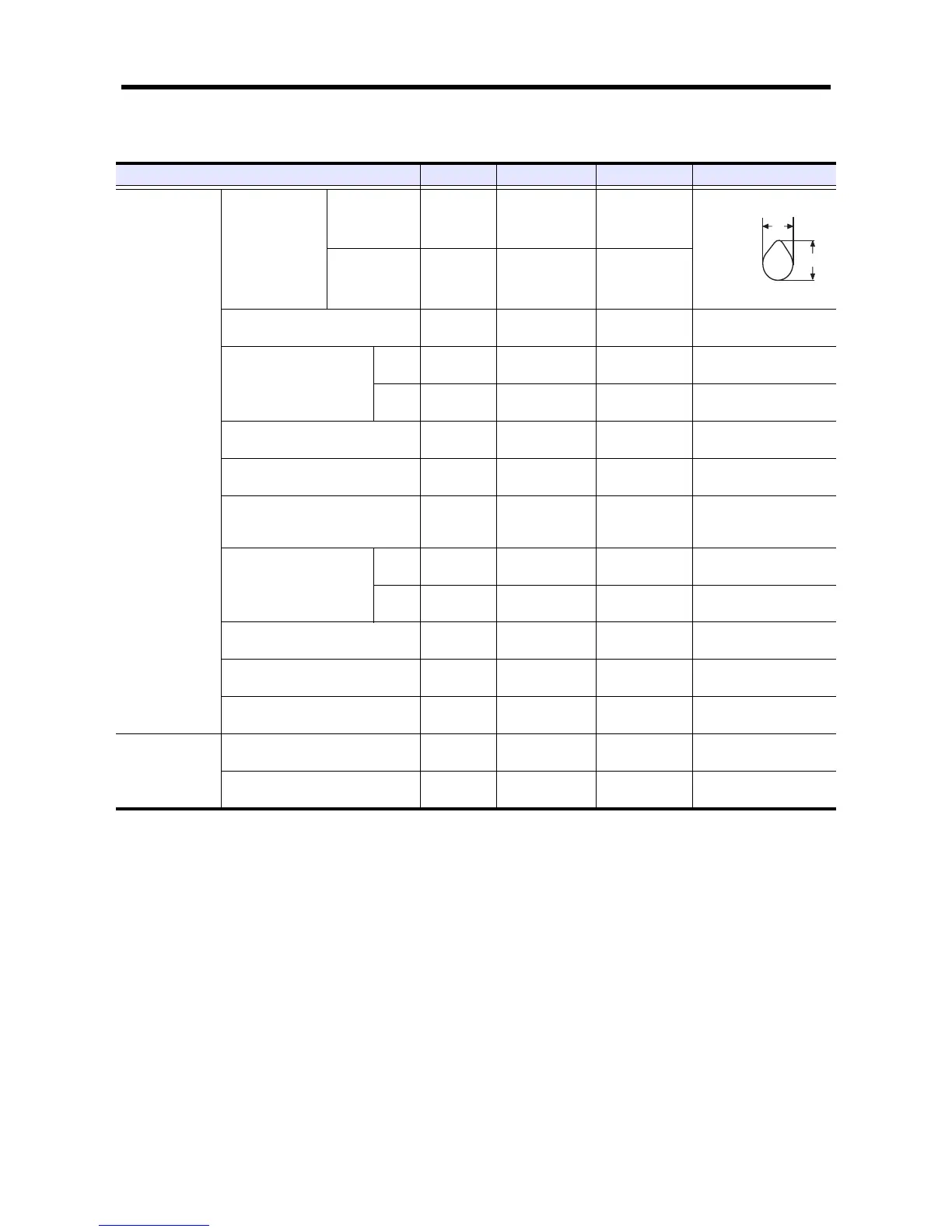

SERVICE DATA

2-5

Camshaft

Cam lift

(D

1 - D2)

Inlet

Major axis

46.916

-0.3

+0.1

[1.8471 -0.012

+0.004

]

Major axis -

minor axis =

6.684 [0.2631]

Major axis -

minor axis =

6.184 [0.2435]

Exhaust

Major axis

45.944

-0.3

+0.1

[1.8088 -0.012

+0.004

]

Major axis -

minor axis =

7.344 [0.2891]

Major axis -

minor axis =

6.844 [0.2694]

Runout

0.04 [0.0016]

or less

0.10

[0.0039]

Repaor the runout,

or replace.

Journal outside diameter

No.1,

No.2

ø 54

[2.13]

53.94 to 53.96

[2.1236 to 2.1244]

53.90

[2.1220]

No.3

ø 53

[2.09]

52.94 to 52.96

[2.0842 to 2.0850]

52.90

[2.0827]

Circularity of journal

0.02

[0.0008] or less

Cylindericity of journal

0.02

[0.0008] or less

Clearance between camshaft journal

outside diameter and crankcase hole

inside diameter.

0.07 to 0.11

[0.0028 to 0.0043]

0.15

[0.0059]

Camshaft hole inside diame-

ter

No.1,

No.2

ø 54

[2.13]

54.03 to 54.05

[2.1272 to 2.1279]

No.3

ø 53

[2.09]

53.03 to 53.05

[2.0878 to 2.0886]

Circularity of camshaft hole

0.02

[0.0008] or less

Camshaft hole coaxiality

0.05

[0.0020] or less

End play

5

[0.20]

0.10 to 0.25

[0.0039 to 0.0098]

0.30

[0.0118]

Replace thrust plate.

Tappet

Tappet hole inside diameter

ø 14

[0.55]

14.000 to 14.018

[0.5512 to 0.5519]

14.100

[0.5551]

Clearance between crankcase

0.016 to 0.052

[0.0006 to 0.0020]

0.080

[0.0031]

Table 2-2 Maintenance service data table - Basic engine (4 / 5) Unit: mm [in.]

Inspection point Nominal Standard Limit Remark

D

1

D

2

Loading...

Loading...