INSPECTION AND REPAIR OF BASIC ENGINE

6-6

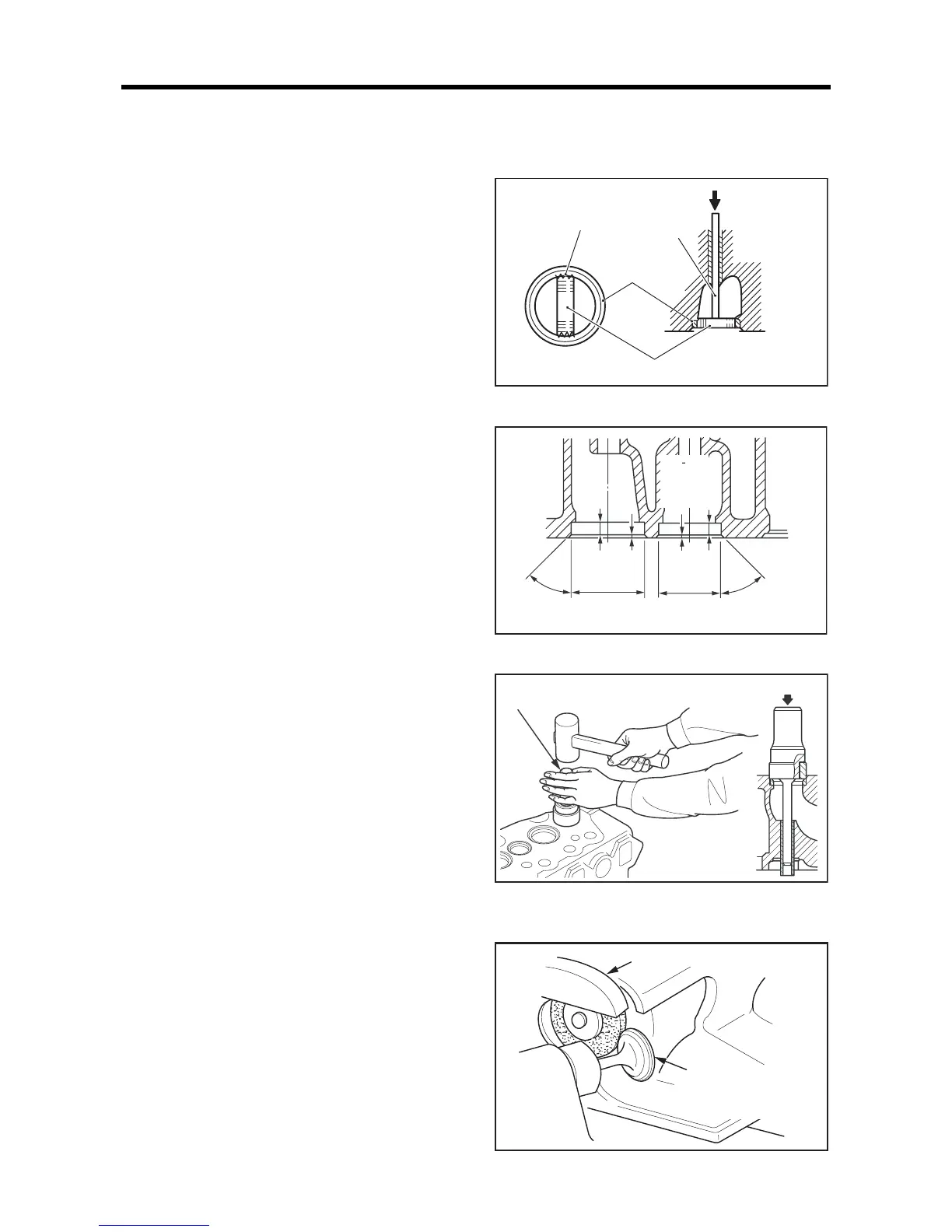

1.8 Replacing valve seat

(1)

To remove the valve seat, weld a stud to the valve seat

as illustrated. Then, insert a rod into the valve guide

hole from the top of the cylinder head, and press out the

valve seat with the rod.

Note: Be careful not to allow spatters to adhere to the

machined surface of the cylinder head during

welding.

Removing valve seat using valve seat puller

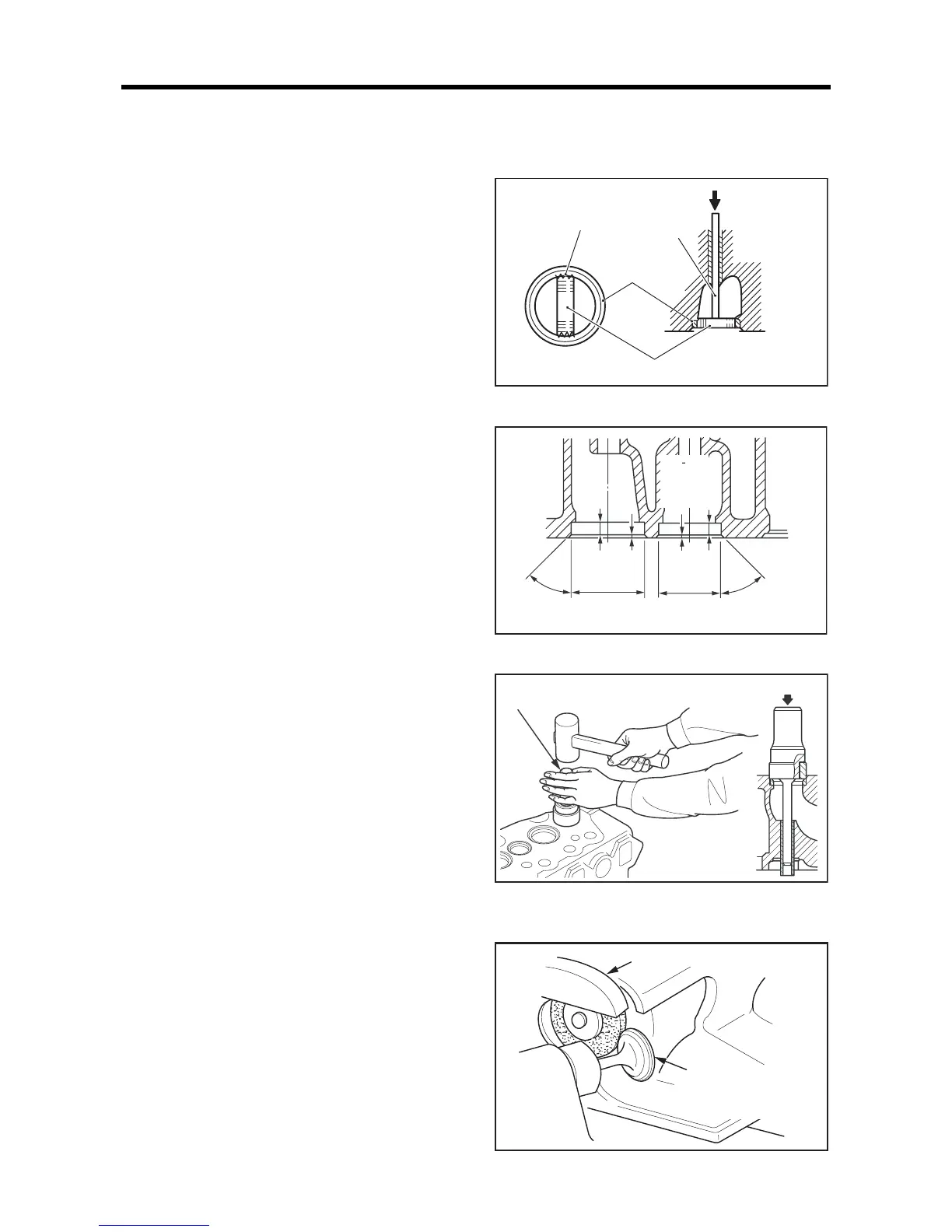

(2) Before inserting a new valve seat, measure the cylinder

head bore diameter to make sure the interference meets

the specified value.

Valve seat fitting bore

(3) Cool the valve seat for four minutes or more in liquid

nitrogen (at approximately -170°C [-274°F]) before

fitting it into the cylinder head, while keeping the

cylinder head at room temperature. Or heat the cylinder

head to 80 to 100°C [176 to 212°F] and cool the valve

seat sufficiently in ether or alcohol mixed with dry ice

before fitting it into the hot cylinder head.

(4) Fit the cold valve seat into the cylinder head using a

insert caulking tool.

Driving in valve seat

1.9 Refacing valve face

If the valve face is significantly worn out, reface the valve

face using a valve refacer.

Note: (a) Grind the valve face using the valve refacer at the

specified angle.

(b) Secure the valve margin width equal to or greater

than the limit. If the dimensions after refacing

does not meet the specified values, replace the

valve with a new one.

Refacing valve face

Valve seat

Weld

Stud

Shaft

45°45°

Inlet Exhaust

Unit: mm [in.]

8.8 ± 0.1

[0.346 ± 0.0039]

2.8 ± 0.1

[0.110 ± 0.0039]

2.8 ± 0.1

[0.110 ± 0.0039]

ø41

+0.02

0

[1.61

+0.008

0

]

ø33

+0.02

0

[1.30

+0.008

0

]

8.8 ± 0.1

[0.346 ± 0.0039]

Insert caulking tool

(Inlet) P/N:30691-02700, (Exhaust) P/N:30691-02800

Set the valve face

angle at the specified

angle.

Valve refacer

Loading...

Loading...