INSPECTION AND REPAIR OF BASIC ENGINE

6-19

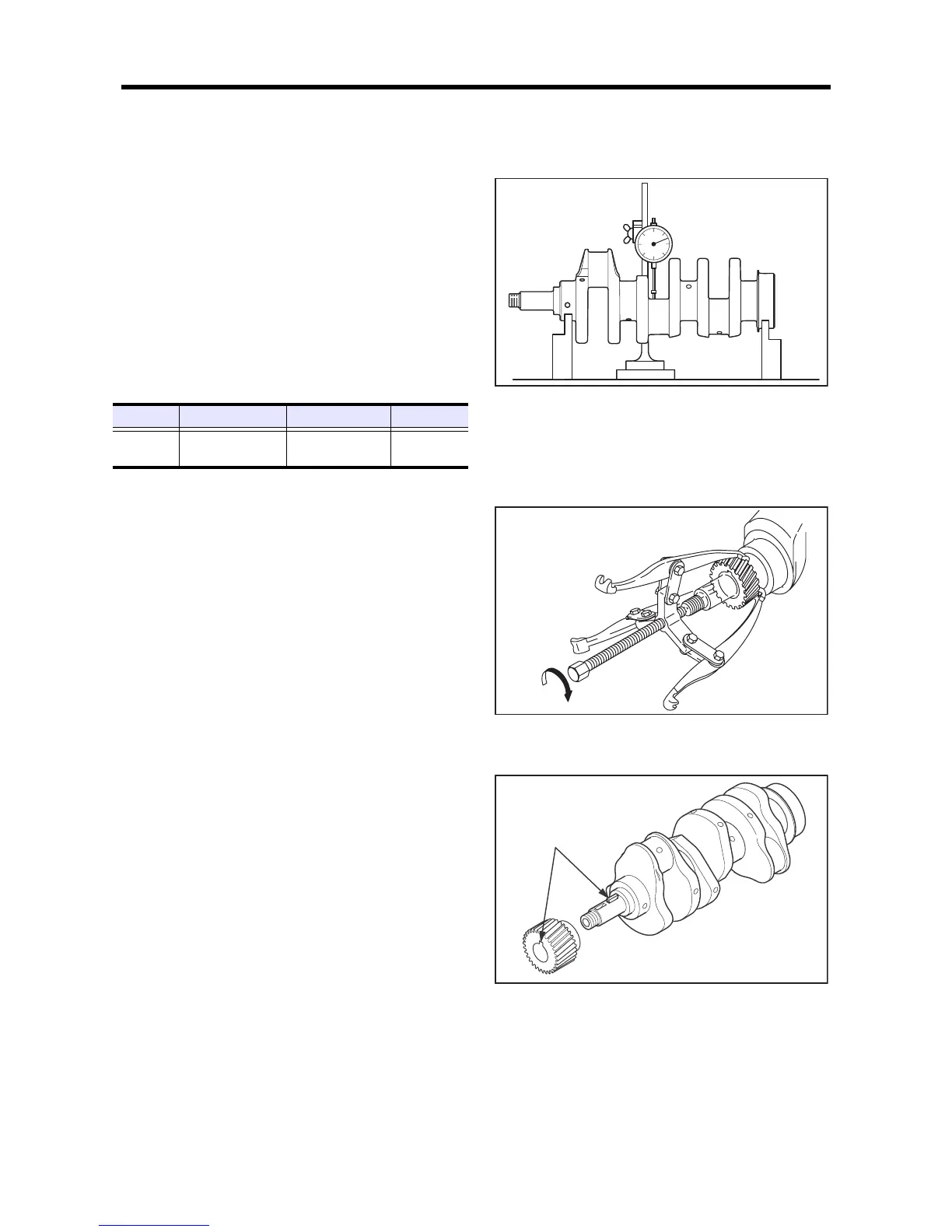

4.11 Measuring crankshaft runout

Support the crankshaft at the front and rear journals with V-

blocks, and measure the crankshaft runout at the center

journal using a dial gauge. If the runout deviates from the

standard only slightly, grind the crankshaft to repair. If the

runout exceeds the standard considerably, straighten the

crankshaft using a press.

If the limit is exceeded, replace the crankshaft.

If the crankshaft has been repaired by grinding or pressing,

inspect the crankshaft for cracks and other harmful damage

using a magnetic particle method.

Measuring crankshaft runout

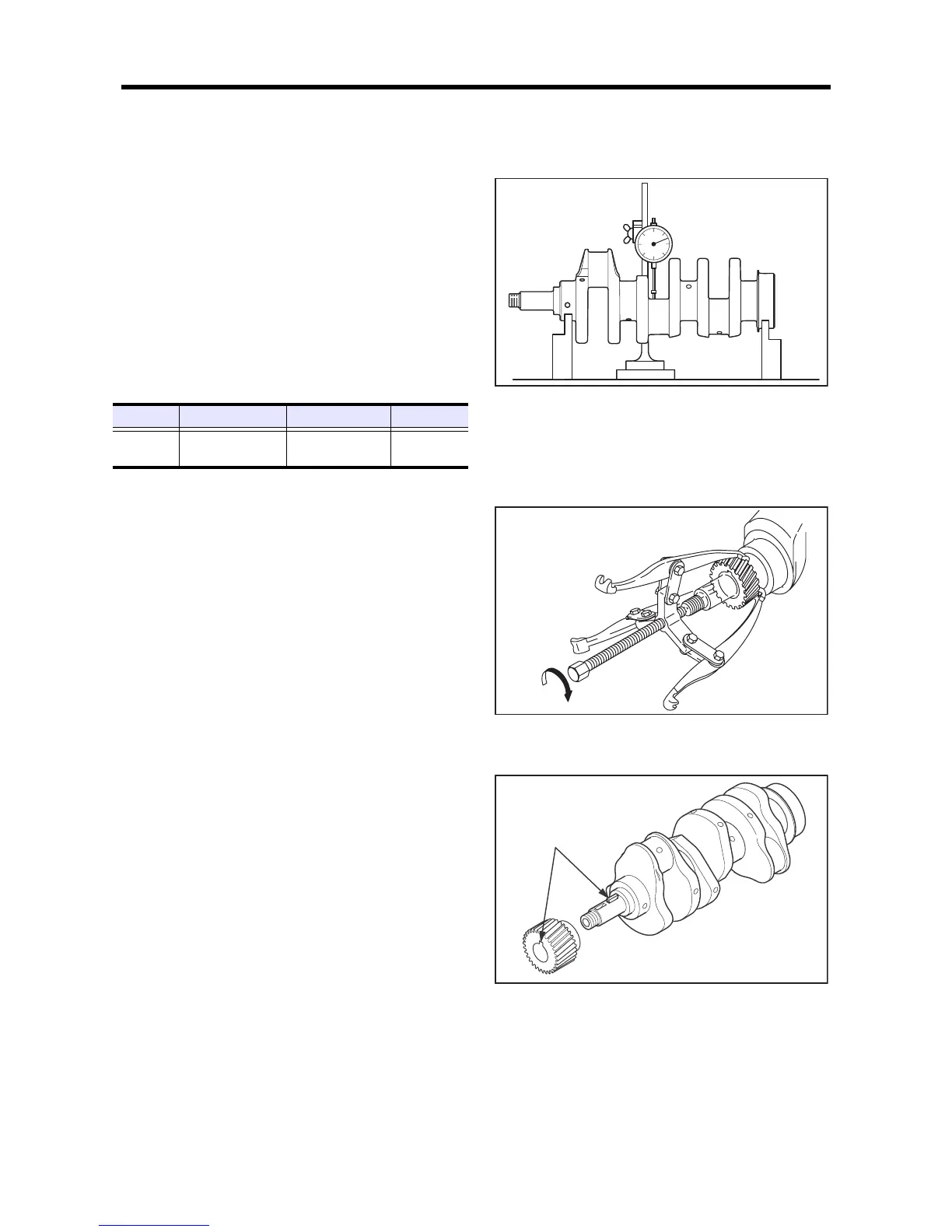

4.12 Removing crankshaft gear

Using a gear puller, remove the gear from the crankshaft.

Note: Do not strike the gear with a hammer.

Removing crankshaft gear

4.13 Installing crankshaft gear

(1)

Install the key on the crankshaft.

(2) Press-fit the gear fully in alignment with the key.

Installing crankshaft gear

Item Standard Limit Remark

Crankshaft

runout

0.04 mm

[0.0016 in.] or less

0.10 mm

[0.0039 in.] or less

TIR

Align them

Loading...

Loading...