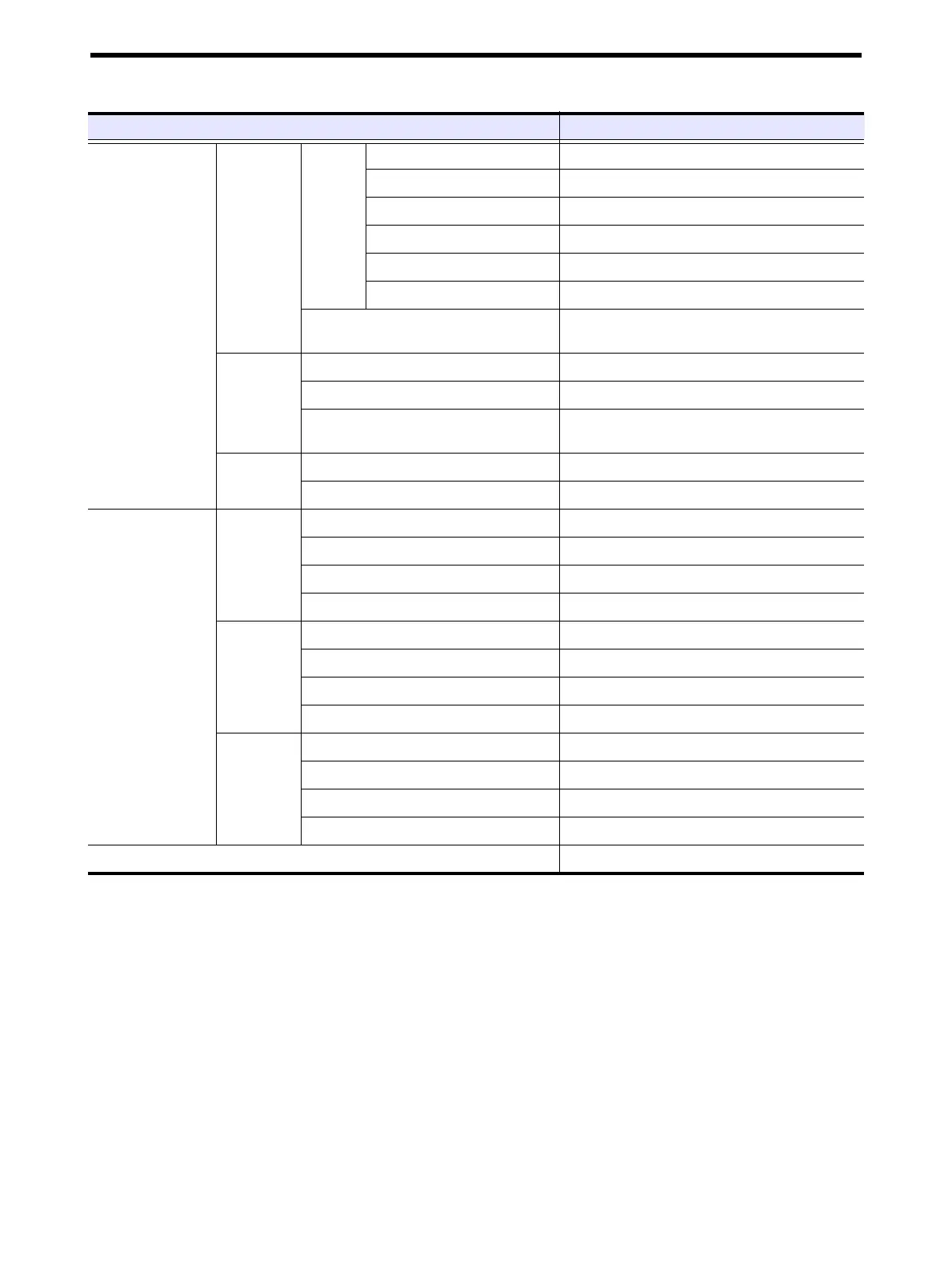

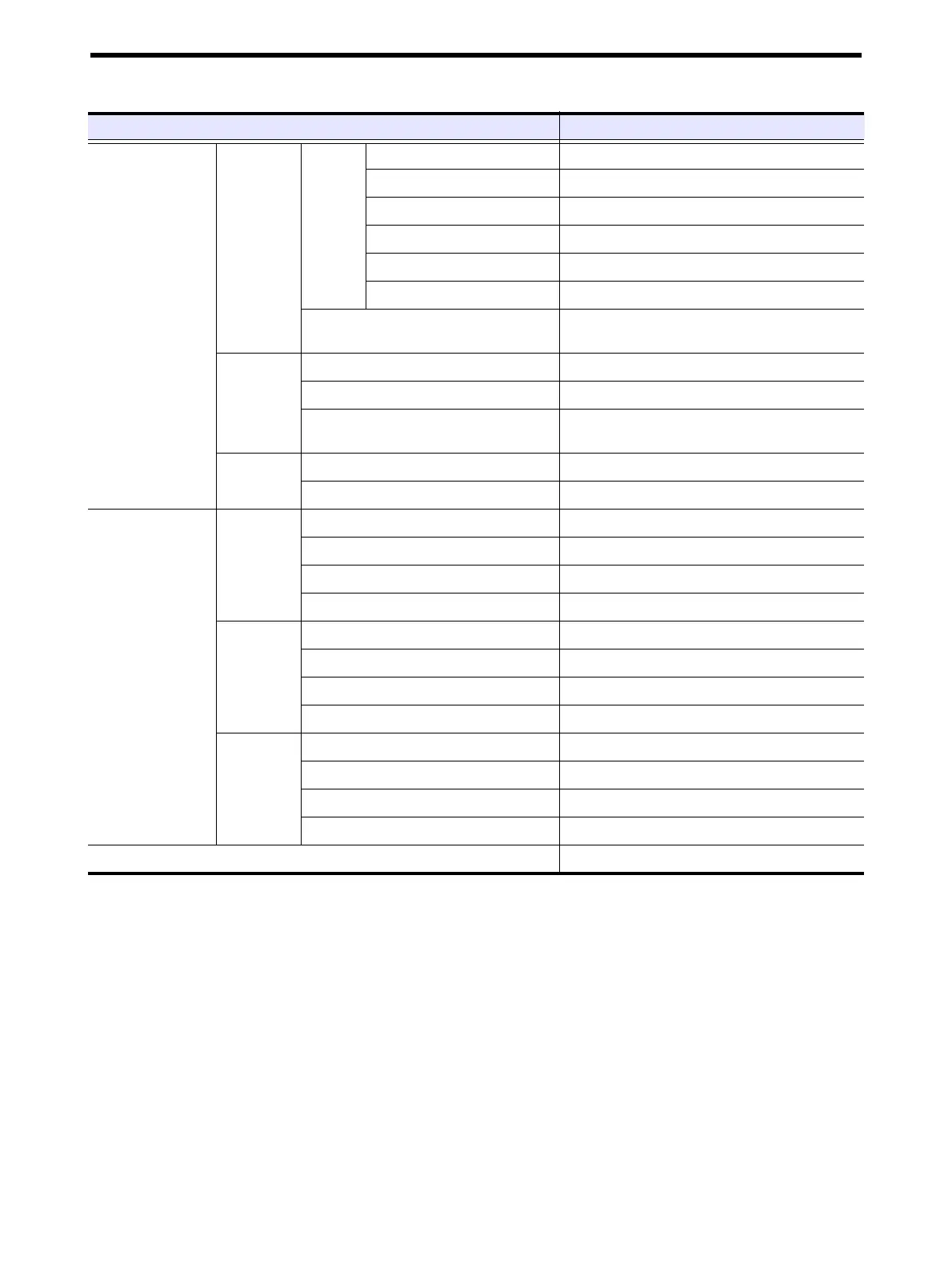

6-4

Chapter 6 COOLANT

Circulation metal-

lic causticity

(88 ± 3°C [190 ±

5.4°F],

1000 ± 2 Hr,

30 vol % (E.G))

Test Piece

Mass

change

Aluminum ±0.60 mg/cm

2

Cast iron ±0.30 mg/cm

2

Steel ±0.30 mg/cm

2

Brass ±0.30 mg/cm

2

Solder ±0.60 mg/cm

2

Copper ±0.30 mg/cm

2

External of test piece after the exam-

ination

Not corrosion on surface excluding between

test piece and spacer. Discoloration is OK.

Properties

of liquid

after the

examina-

tion

pH 6.5 to 11.0

pH change Maximum ±1.0

External of liquid Not remarkable discoloration, separation

and gel.

Condition

of parts

Pump seal Not trouble while the examination

Inside of pump case and blade Not remarkable corrosion

Rubber adapt-

ability

(30 vol %,

115 °C [239 °F],

360 Hr)

Silicon

Tensile strength change -60 to 0%

Elongation change -40 to +20%

Volume change 0 to +40%

Hardness change -20 to +10%

Acrylo-

nitrile buta-

diene

rubber

Tensile strength change 0 to +10%

Elongation change -15 to +15%

Volume change 0 to +40%

Hardness change -10 to 0%

Ethylene

propylene

diene

monomer

Tensile strength change 0 to +10%

Elongation change -30 to 0%

Volume change 0 to +10%

Hardness change -10 to 0%

Storage stability vol % (30 vol %, room temperature, 6 Hr) Maximum 0.3

Table 6-2 LLC specification

Property Standard value

Loading...

Loading...