7-9

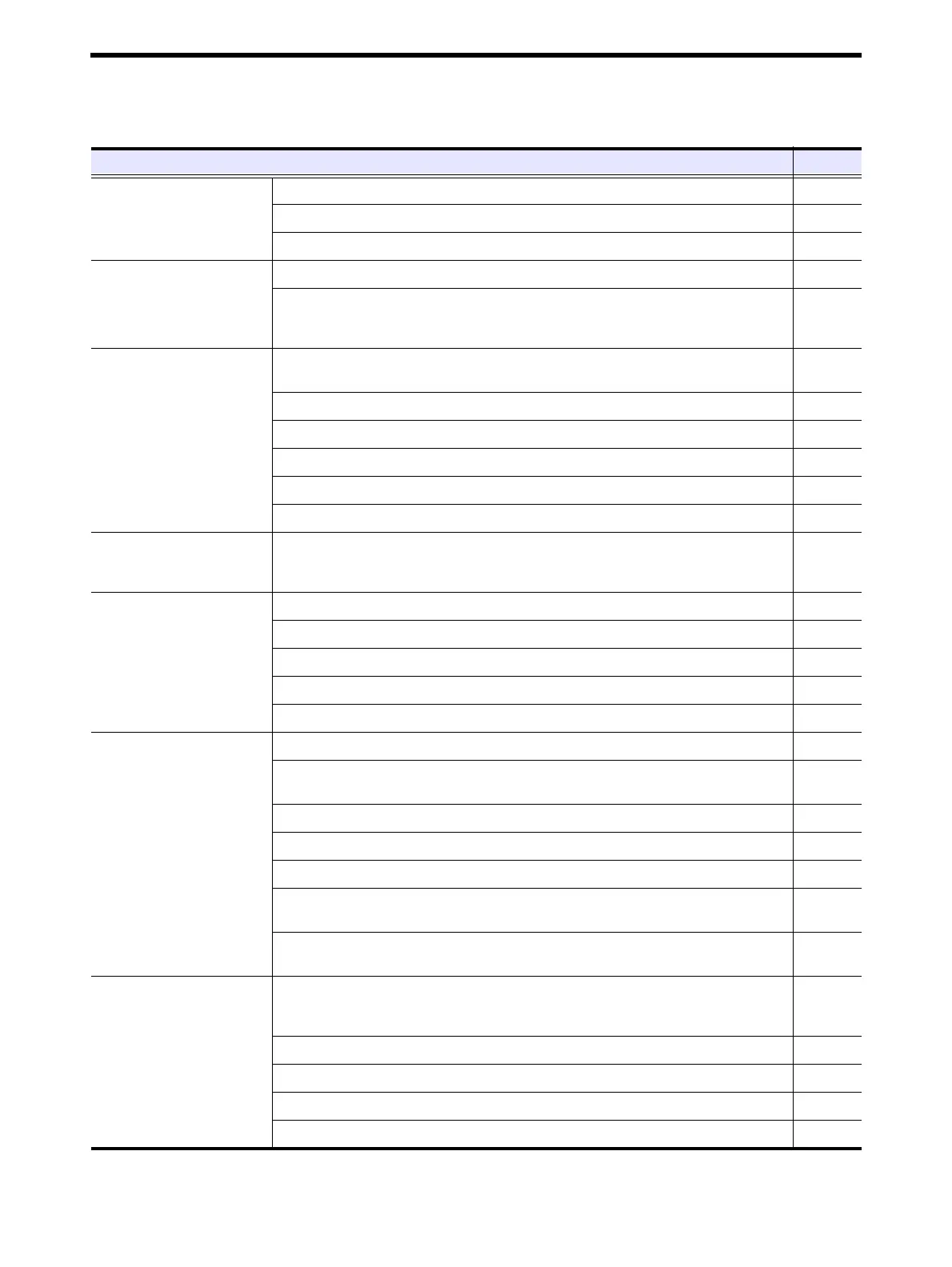

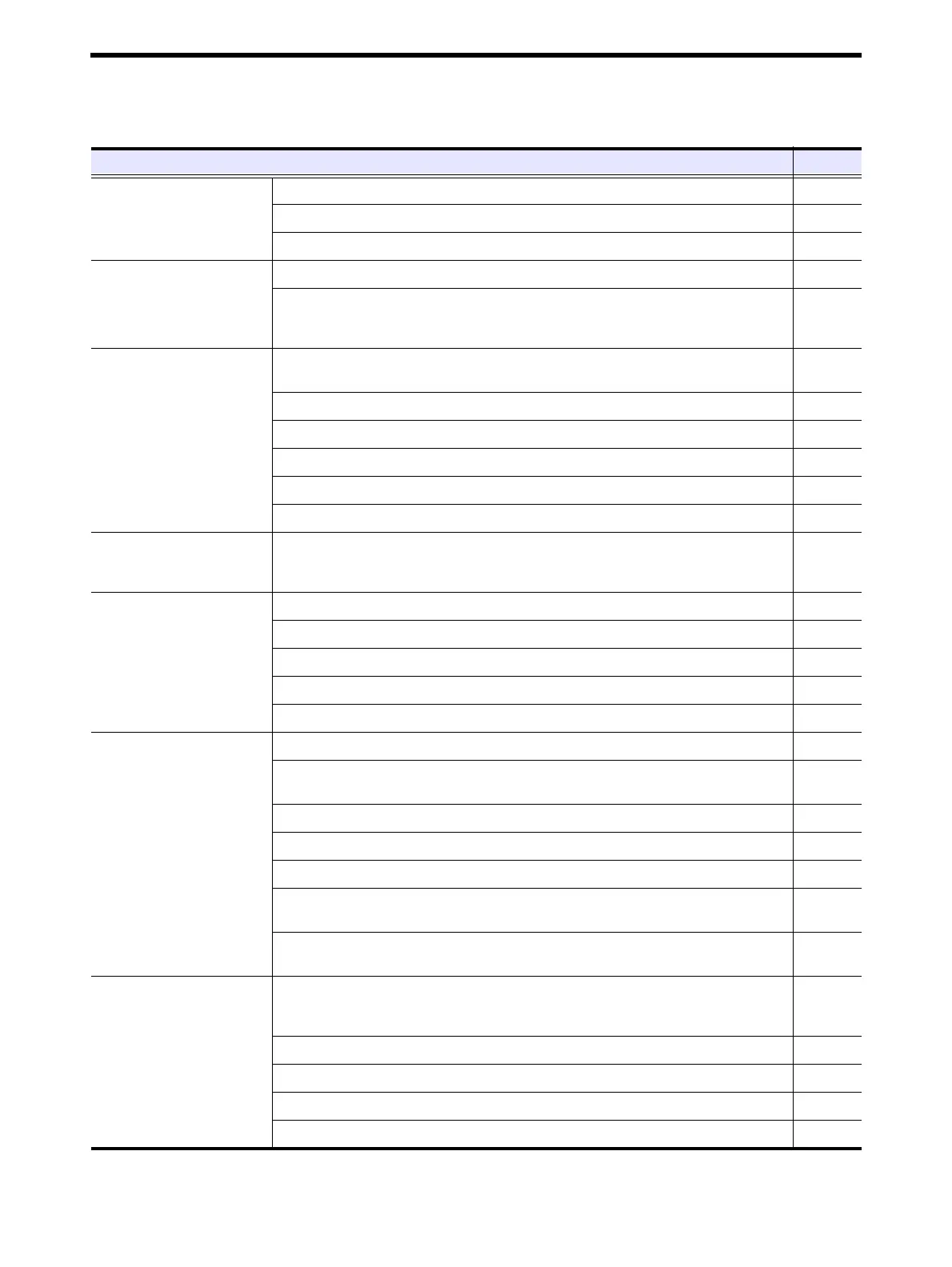

Chapter 7 MAINTENANCE SCHEDULE

Periodic maintenance chart for general purpose engine

Table 7-3 Periodic maintenance chart for general purpose engine

Interval and Service item Page

Every 50 service hours or

every month

Fuel control linkage ball joint - Inspect 8-6

Air strainer - Drain water and Clean (air motor type or direct inlet type) 8-20

Air tank - Drain water (air motor type or direct inlet type) 3-11

First 50 service hours for

a new or overhauled

engine

Bolts and nuts on the engine - Retighten *

Engine oil, Oil filter and Bypass oil filter - Replace

It is recommended to check the engine oil characteristics at the same time.

The oil filters must be replaced when the filter alarm lights.

8-10

Every 250 service hours

or every 1 year

Engine oil, Oil filter and Bypass oil filter - Replace

The oil filters must be replaced when the filter alarm lights.

8-10

Governor oil filter - Replace 8-12

V-belt and belt tension - Inspect and Adjust 8-2

Radiator fins - Check and Clean 8-14

Draining water from the exhaust muffler 8-15

Air tank - Inspect safety valve operation (air motor type or direct inlet type) 8-20

First 250 service hours

for a new or overhauled

engine

Valve clearance - Inspect and Adjust

(Check valve mechanism at the same time.)

*

Every 1000 service hours

or every 2 years

Fuel filter - Replace 8-8

Water separator - Inspect and Replace 8-7

Gauze filter - Clean 8-7

Air strainer - Drain water and Clean (air motor type or direct inlet type) 8-20

Zinc Rod - Replace *

Every 2000 service hours

or every 3 years

Bolts and nuts on the engine - Retighten *

Valve clearance - Inspect and Adjust

(Check valve mechanism at the same time.)

*

Fuel injection timing - Inspect and Adjust *

Fuel pipe - Inspect 8-9

Oil pipe - Inspect 8-12

Fuel injection nozzle - Nozzle tip replacement (Check the spray condition

and adjust the fuel injection pressure after replacement)

*

Protection devices operation - Inspect (high water temperature, low oil pres-

sure, overspeed)

*

Every 4000 service hours

or every 5 years

Top end of the engine - Overhaul

Remove the cylinder head, and inspect and service the combustion cham-

bers.

*

Fuel control linkage ball joint - Inspect 8-6

Damper - Inspect 8-3

Air cooler - Clean *

Heat exchanger - Wash *

Loading...

Loading...