SERVICE DATA

2-11

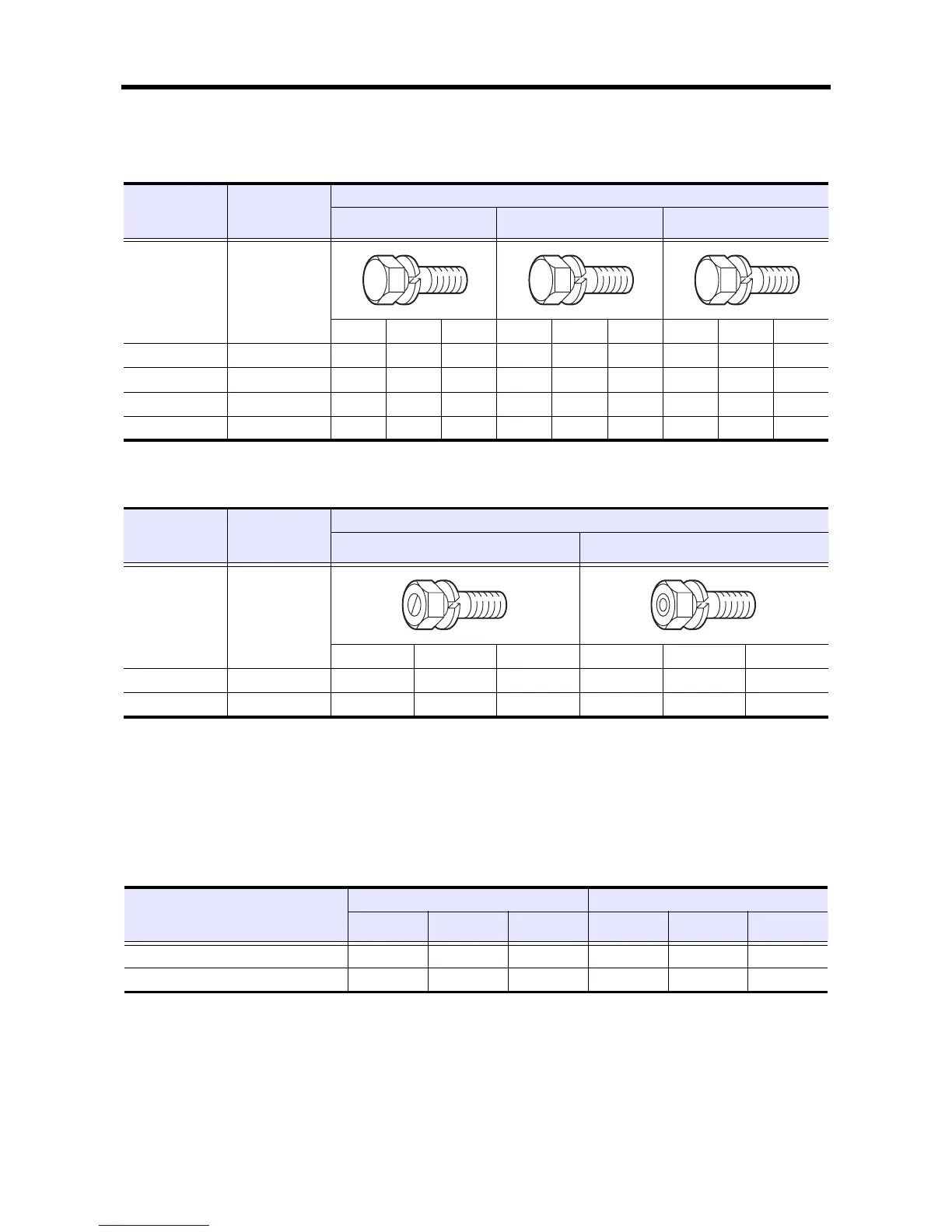

2.2 Standard bolt and nut tightening torque

2.2.1 Metric automobile screw thread

2.2.2 Metric course screw thread

Note: (a) This table lists the tightening torque for standard bolts and nuts.

(b) The numerical values in the table are for fasteners with spring washers.

(c) The table shows the standard values with a maximum tolerance value of ±10%.

(d) Use the tightening torque in this table unless otherwise specified.

(e) Do not apply oil to threaded portions. (Dry)

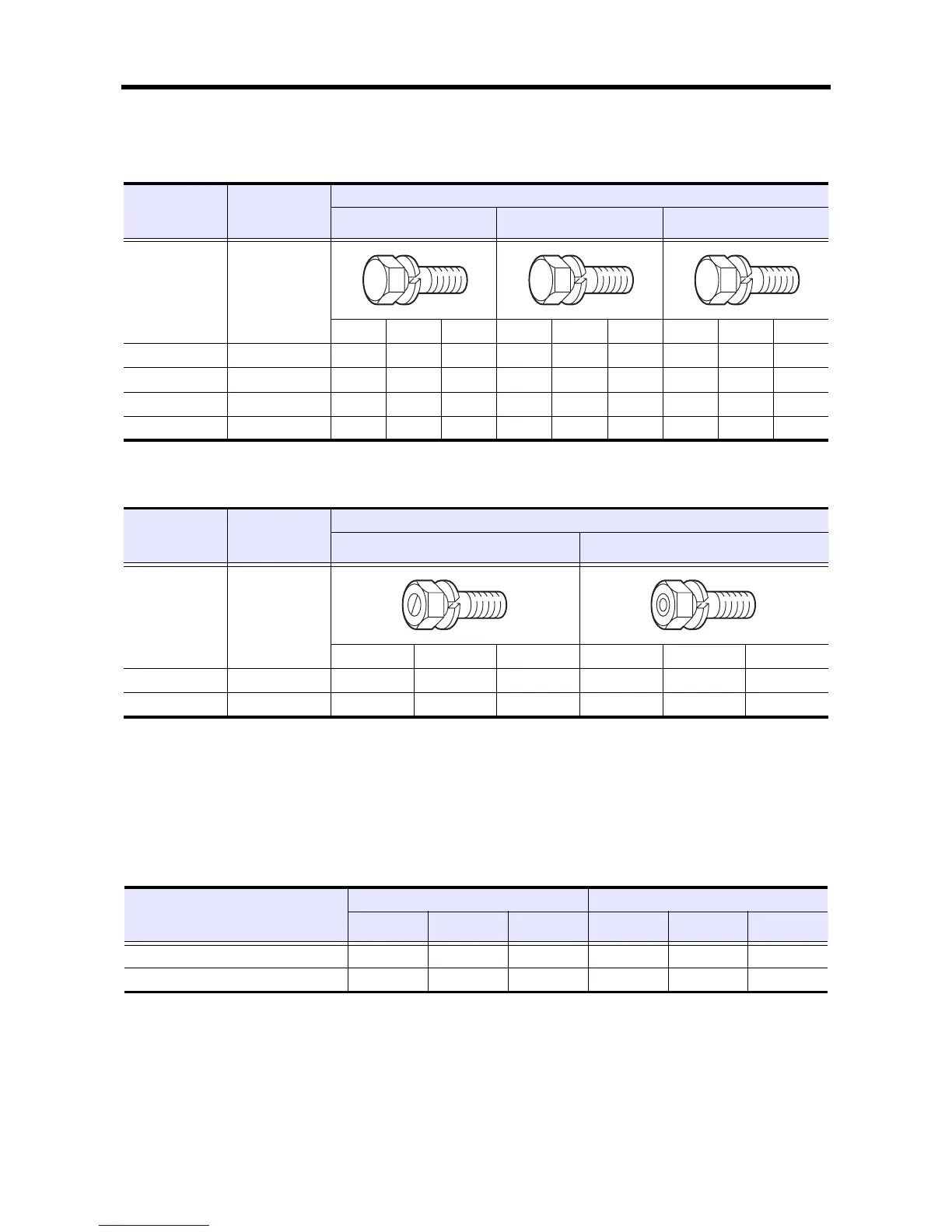

2.3 Standard stud tightening torque

Table 2-14 Metric automobile screw thread

Threads

Dia × Pitch

(mm)

Width

across flats

(mm) [in.]

Strength classification

4T 7T 10.9

N·m kgf·m lbf·ft N·m kgf·m lbf·ft N·m kgf·m lbf·ft

M6 × 1.0 10 [0.39] 3.9 0.4 2.9 8.8 0.9 6.5 12.7 1.3 9.4

M8 × 1.25 12 [0.47] 11.8 1.2 8.7 18 1.9 13 30 3.1 22

M10 × 1.25 14 [0.55] 21.1 2.15 16 35 3.6 26 60 6.1 44

M12 × 1.25 17 [0.67] 35.3 3.6 26 64 6.5 47 108 11.0 80

4 7

10

Table 2-15 Metric course screw thread

Threads

Dia × Pitch

(mm)

Width

across flats

(mm) [in.]

Strength classification

7T 10.9

N·m kgf·m lbf·ft N·m kgf·m lbf·ft

M10 × 1.5 14 [0.55] 32 3.3 24 58 5.9 43

M12 × 1.75 17 [0.67] 57 5.8 42 102 10.4 75

Table 2-16 Standard stud tightening torque

Threads

Dia × Pitch

(mm)

For driving in aluminum materials For driving in ferrous materials

N·m kgf·m lbf·ft N·m kgf·m lbf·ft

M8 × 1.25 5.4 ± 0.5 0.55 ± 0.05 4.0 ± 0.4 13.7 ± 1.0 1.4 ± 0.1 10.1 ± 0.7

M10 × 1.25 12.7 ± 1.0 1.3 ± 0.1 9.4 ± 0.7 23.5 ± 2.0 2.4 ± 0.2 17.4 ± 1.4

Loading...

Loading...