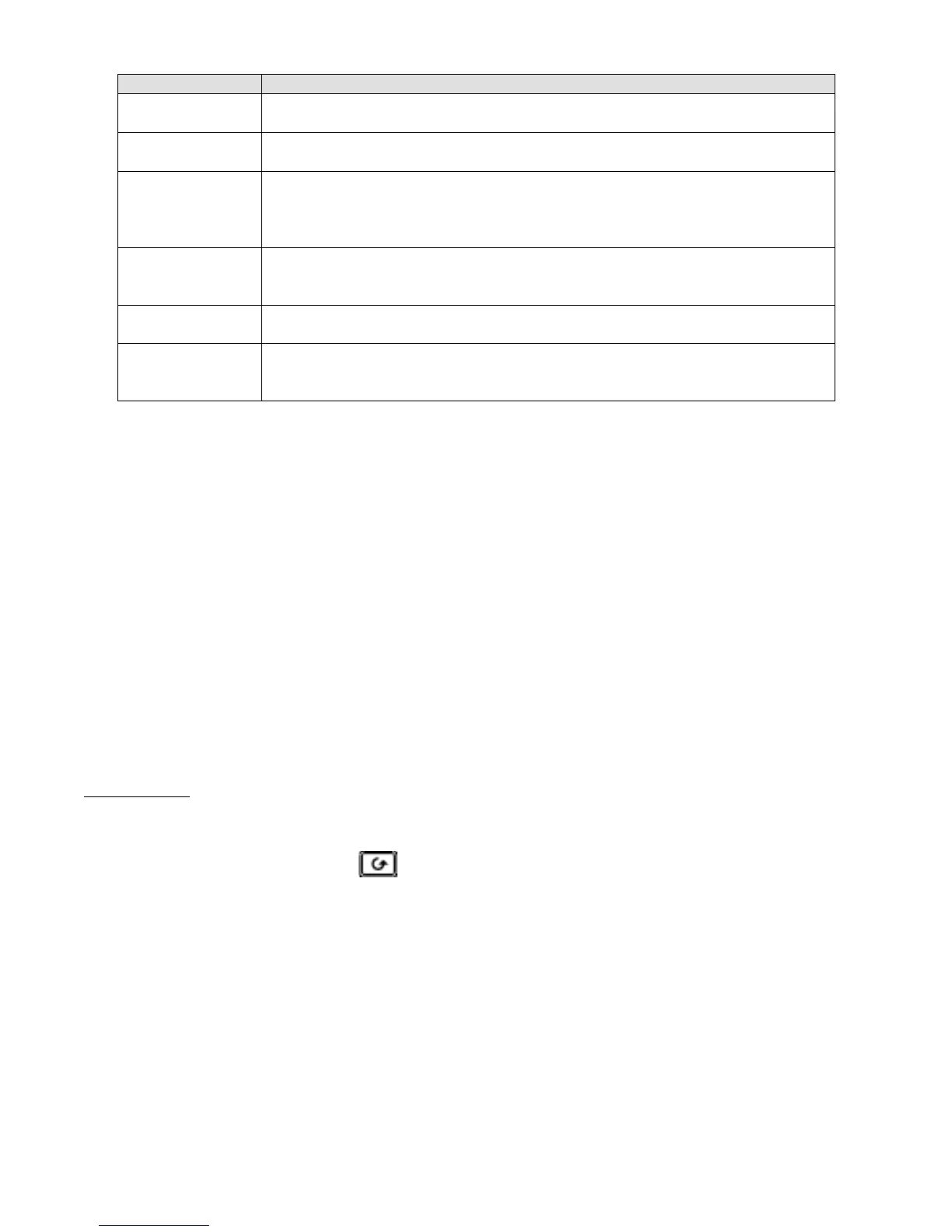

The controller uses a one shot tuner which automatically sets up the initial values of the

parameters listed in the table.

The ‘one-shot’ tuner works by switching the output on and off to induce an oscillation in the

measure value. From the amplitude and period of the oscillation, it calculates the tuning parameter

values.

If the process cannot tolerate full heating or cooling being applied, then the levels can be restricted

by setting the high power limit (‘O P .HI’) and low power limit (‘O P .LO’). However, the measured

value must oscillate to some degree for the tuner to be able to calculate values.

A One-Shot tune can be performed at any time, but normally it is performed only once during the

initial commissioning of the process. However, if the process under control subsequently becomes

unstable (because its characteristics have changed), you can re-turn again for the new conditions.

It is best to start tuning with the process at ambient conditions and with the SP close to the normal

operating level. This allows the tuner to calculate more accurately the low cutback and high

cutback values that restrict the amount of overshoot or undershoot.

How to Tune:

Set the setpoint to the value at which you will normally operate the process.

Operator level 1 list, press, until A.Tune appears. Set to ON.

Press the Page and Scroll buttons together to return to the Home display. The display will

flash [tunE] to indicate that tuning is in progress.

After one (1) minute to determine steady state conditions the controller will induce an

oscillation in the temperature by turning the output on and then off. The first cycle will not

complete until the measured value has reached the required setpoint.

Loading...

Loading...