FG038 MK2 Divider RevA19 13-02-19 23

10 Load dough into hopper.

11 Run the machine and check first dough pieces out of discharge conveyor for

weight and cleanliness. Normally the first six dough pieces are put back into

the hopper as weight consistency is normally suspect in the initial dough

pieces. If any dough pieces are contaminated with excess oil or traces of

previous doughs eg. Wholemeal, discard accordingly.

Note: It is advisable to thoroughly check hopper - divider head - and offtake

conveyor for traces of previous doughs to prevent contamination.

12 Adjust for weight of dough piece required (refer to Setting and Machine

Adjustments, section 10.0).

13 Adjust moulding pressure as required,(refer to Setting and Machine

Adjustments, section 10.0).

14 Check oil level in tank (40) frequently throughout shift and top up, if required.

15 Run dough through divider. Care must be taken with weights especially

towards end of dough.

Note:- The divider is a volume divider which divides by size of dough piece,

not by weight. Be aware that dough is a “live” product and will expand in

size during the dividing process.

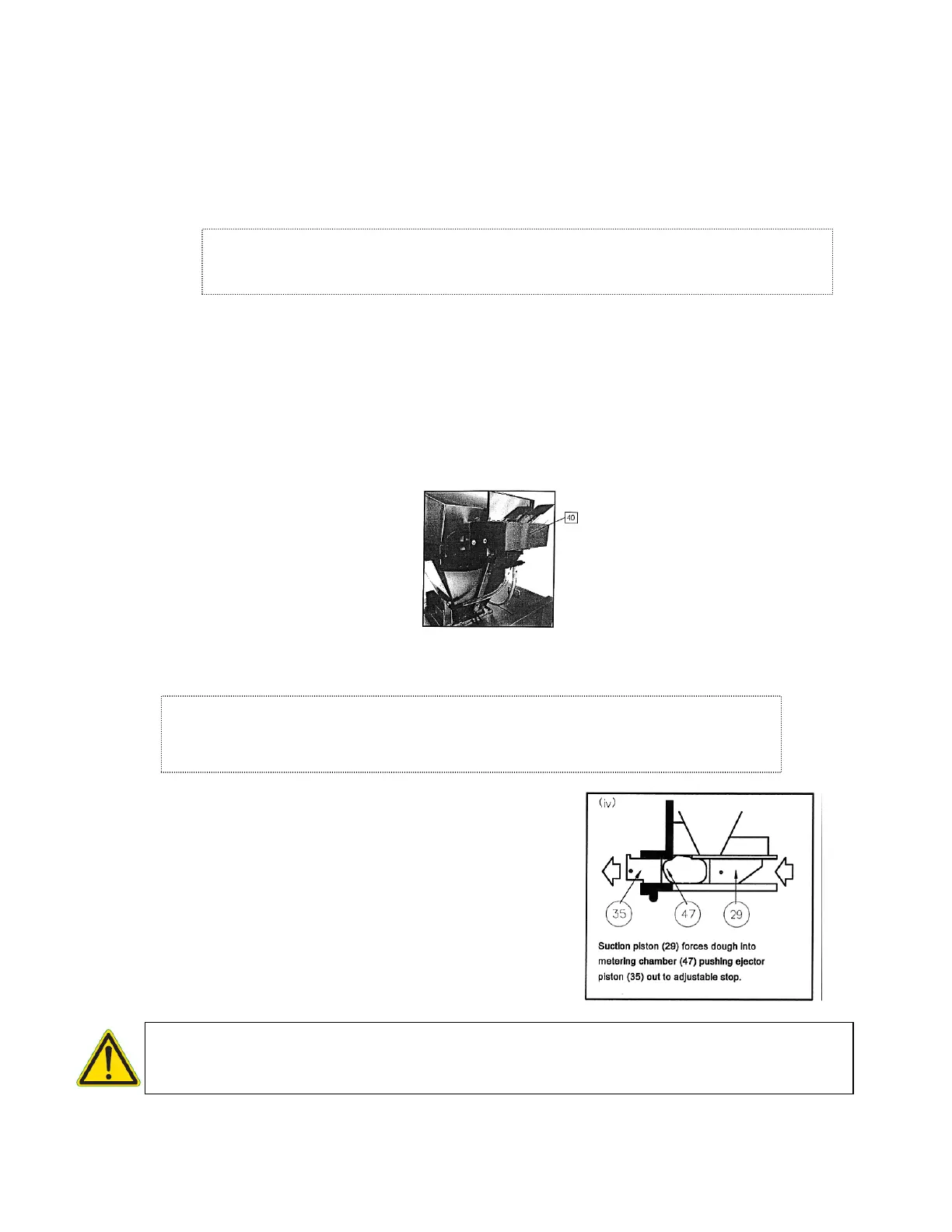

16 After use, stop machine in position “iv” of

dividing cycle to conserve oil on suction

piston and knife.

WARNING! NEVER LEAVE MACHINE WITH DOUGH IN SUCTION CHAMBER, AS

DANGEROUS PRESSURES CAN BUILD UP AS THE DOUGH PROVES

Loading...

Loading...