Moog | Installation instructions series G400

English

09/2008

Introduction

Brushless construction means that MOOG G400 series

servodrives are maintenance free. The longevity of the

motors is limited only by the life of the bearings, which

have a lifetime lubrication (a minimum of 20,000 opera-

tion hours with the recommended maximum axial and

radial loads). Because of product liability issues any

motor damage should be repaired by MOOG, non MOOG

staff may be unable to comply with safety rules (e.g. VDE

guidelines) and MOOG quality standards.

Caution: Destruction of the paint seal on the screws

voids warranty.

Recommended drives to be used to control the motor,

according to UL1004, Par.30.6: MSD Series, DS2000 by

Moog.

Shipment

Please check the contents of delivery are as ordered

and that no damage, especially the areas of the shaft

and connectors, has occurred during transit. Any prob-

lems should be immediately addressed to MOOG with a

description of the fault or damage.

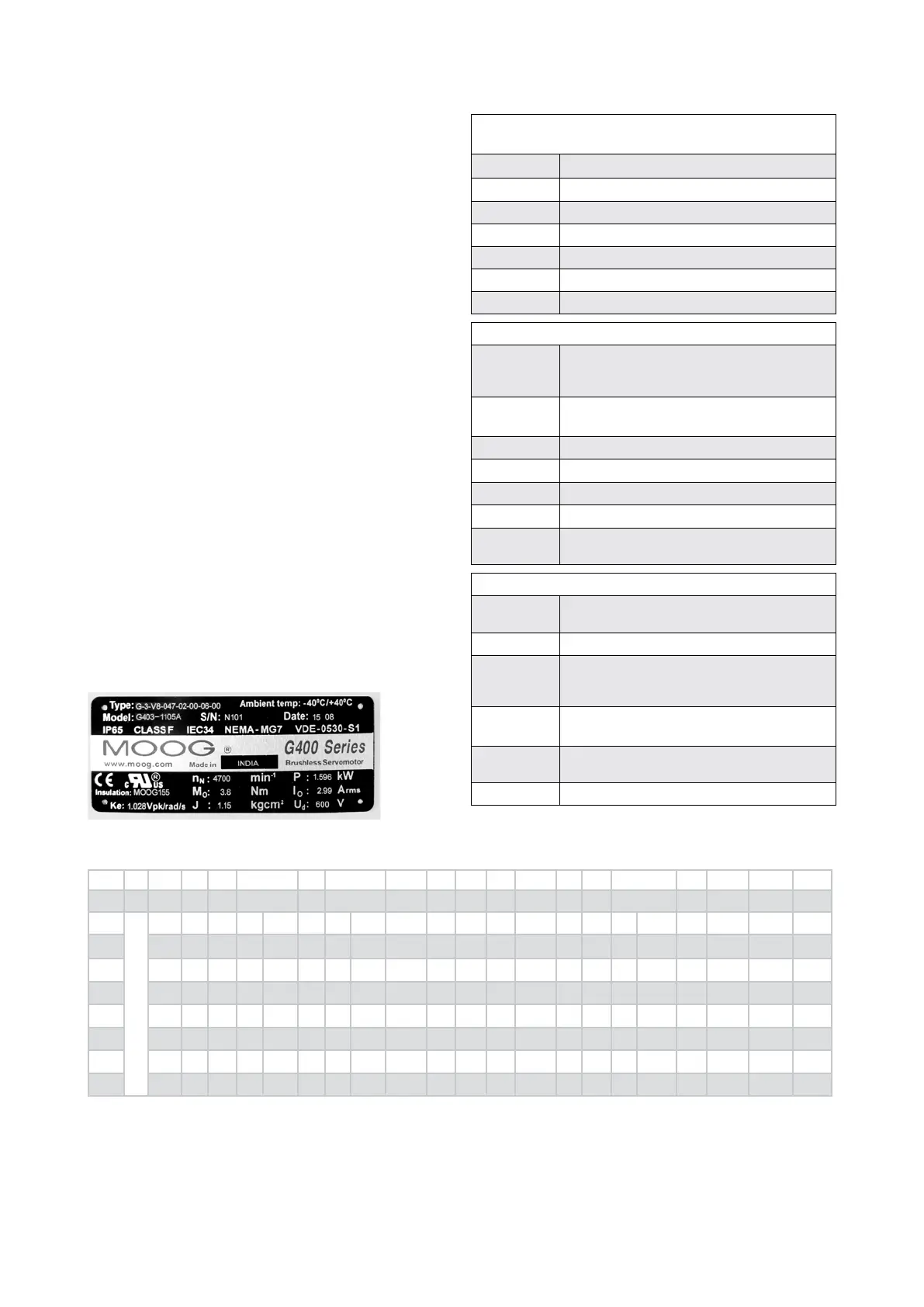

G400 series motor codication

The motor nameplate data are used for the setting of the

servodrive. In case of contact with Moog, identication

data of the motor must be supplied.

Example:

Technical data

data are measured at 25°C ambient temperature

n

N

nominal speed at PN

P

N

nominal power (max continuous output power)

M

0

continuous stall torque

I

0

continuous stall current (at M

0

)

K

e

back emf (voltage constant)

J

rotor moment of inertia

U

d

nominal operatine voltage (bus voltage)

Nameplate data

Type

motor type

(Note: for motors built before July 2008 this

may vary)

Ambient

temp

ambient temperature

Model

motor model number (ordering number)

S/N

serial number

Date

week and year of production

Insulation

UL approved insulation system

Brake

Brake is optional. Data provided refers to

holding torque

Standards

IP65

degree of protection. Motor protected against

jets of water (at shaft with seal option)

I.CL.F

motor listed for insulation class F (155°C)

IEC34

motor fullls IEC34 (Standard denes rating

and performance of rotating electrical ma-

chines)

VDE-0530-

S1

performance measurements are done according

to VDE-0530

CE

conformity certicate will be supplied on

request

UL

motor c-UL Recognized, le number E137630

Installation instructions

General

Standards

Technical

data

Mounting dimensions for MOOG motors

Type A Pmax C øAJ øAK AH øU BB

max

øBF XD R S1xS2 D BC øE F G H M

mm mm mm mm mm mm mm mm mm mm mm mm mm mm mm Nm

G-1

See tables at page 13

40 7.0 48 18

+0.008

-0.003

16 6

+0.006

-0.002

2.5 3.3 10 4.8 2x2 1.5 0 14

+0.027

-0.000

- M2.5x8 M3x16 1.3

G-2

55 9.0 63 40

+0.011

-0.005

20 9

+0.010

+0.001

2.5 5.5 14 7.2 3x3 3 0 24

+0.003

-0.000

- M2.5x8 M5x22 5

G-3

70 9.0 75 60

+0.012

-0.007

23 11

+0.012

+0.001

2.5 5.5 16 8.5 4x4 4 0 24

+0.003

-0.000

- M2.5x8 M5x22 5

G-4

100 9.8 115 95

+0.013

-0.009

40 19

+0.015

+0.002

3 9 32 15.5 6x6 4 0 35

+0.039

-0.000

66.3 M4x16 M8x30 16

G-5

140 12.2 165 130

+0.014

-0.011

50 24

+0.015

+0.002

3.5 11 40 20 8x7 5 0 47

+0.039

-0.000

98.8 M4x16 M10x40 30

G-6

190 11.0 215 180

+0.014

-0.011

60 32

+0.018

+0.002

4 13.5 40 27 10x8 10 0 50

+0.039

-0.000

128 M4x16 M12x40 38

ISO

286 286 286 286 286 286 286 286 286 286 286

DIN

6885 6885 13-1 912 8.8 912 8.8

A Length of mot or without shaft, pilot and mating connector

Pmax Maximum width of motor (end view) excluding terminal housing, etc.

C Thickness of ange plate of motor

øAJ Diameter of mounting bolt circle in ange of motor

øAK Diameter of pilot on ange of motor AH Mounting surface of ange of

motor to end of shaft

øU Diameter of shaft extension

BB

max

Maximum height of pilot of mounting ange of motor

øBF Clearance hole in mounting ange of motor

XD Usable length of keyseat

R Bottom of keyseat to opposite side of shaft

S1 Width of key

S2 Height of key

D Distance between end of shaft and key

BC Distance between mounting ange of motor to shoulder shaft

(always=0mm)

øE Diameter of hole for shaft in ange of motor

F Width of motor between recesses for mounting screws

G Thread in motor shaft

H Recommended ange screws (kind and length)

M Tightening torque for ange screws

All dimensions without tolerance are according to DIN ISO 2768, part 1, category c.

2

Loading...

Loading...