Maintenance

C2 Contour Air Drill August 2014 6-7

Important

Turn “Operating” valve out to “Bleed Off/

Service” position and remove all pressure

from hydraulic systems before attempting any

service work on hydraulic components.

Hydraulic system must be bled after it has

been serviced (if any portion of the system

has been opened to atmosphere)

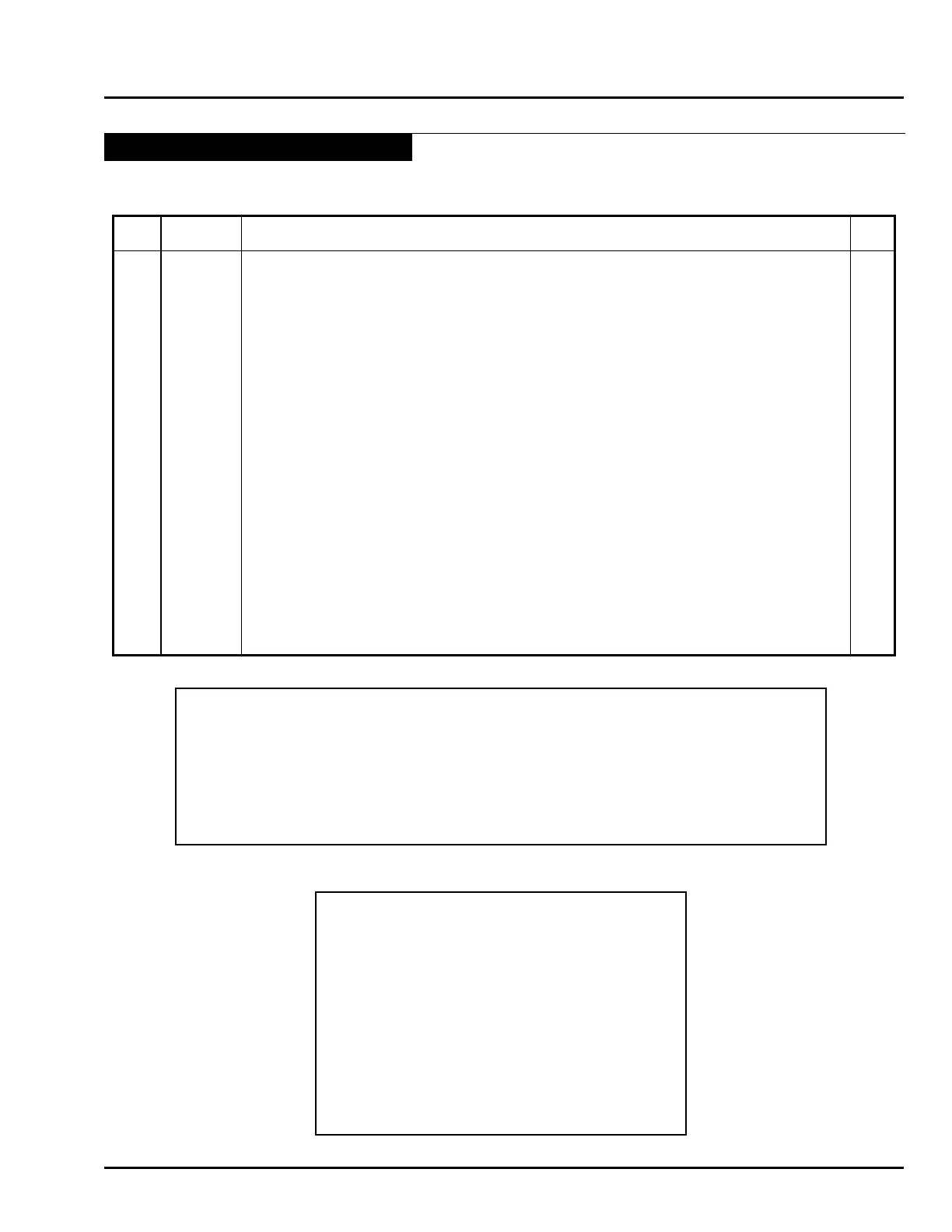

Item Part No. Description Qty

1 C48880 Hydraulic Cylinder - 1-3/4 Bore x 4 Stroke ........................................................................ 1

2 S48860 Base Assembly ................................................................................................................. 1

3 D-5273 Locknut - 3/4 Unitorque .................................................................................................... 3

4 D-5274 Locknut - 1” Unitorque ..................................................................................................... 1

5 S42673 Lipped Pin ........................................................................................................................ 1

6 S42674 Washer - 2-1/2 OD x 25/32 ID x 1/4 ................................................................................. 2

7 S42675 Washer - 1-1/32 ID x 2 OD x 1/8 ....................................................................................... 4

8 S42949 Hex Bolt - 3/4 x 5-1/8 Lg ................................................................................................... 1

9 S42951 Hex Bolt - 3/4 x 6 Lg ......................................................................................................... 2

10 S42952 Hex Bolt -1 x 6-5/8 Lg ....................................................................................................... 1

11 S44397 Cylinder Bushing - 3/4 ID x 1 OD .................................................................................... 6

12 S45450 Mounting Bracket ............................................................................................................. 1

13 S47527 Polygon Fiber Bushing - 1ID x 1-1/4 OD x 1Lg ................................................................. 4

14 S48852 Top Link ............................................................................................................................ 1

15 S48853 Lower Link ........................................................................................................................ 1

16 S49250 Cast Shankholder ............................................................................................................. 1

17 S49290 Opener Body .................................................................................................................... 1

18 S49295 Packer Arm Pivot Bracket ................................................................................................. 1

19 S49514 Packer Pivot Bushing - 3/4 ID x 1 OD x 1-5/16Lg ............................................................. 1

20 W-530 Cotter Pin - 5/32 x 1 Lg..................................................................................................... 1

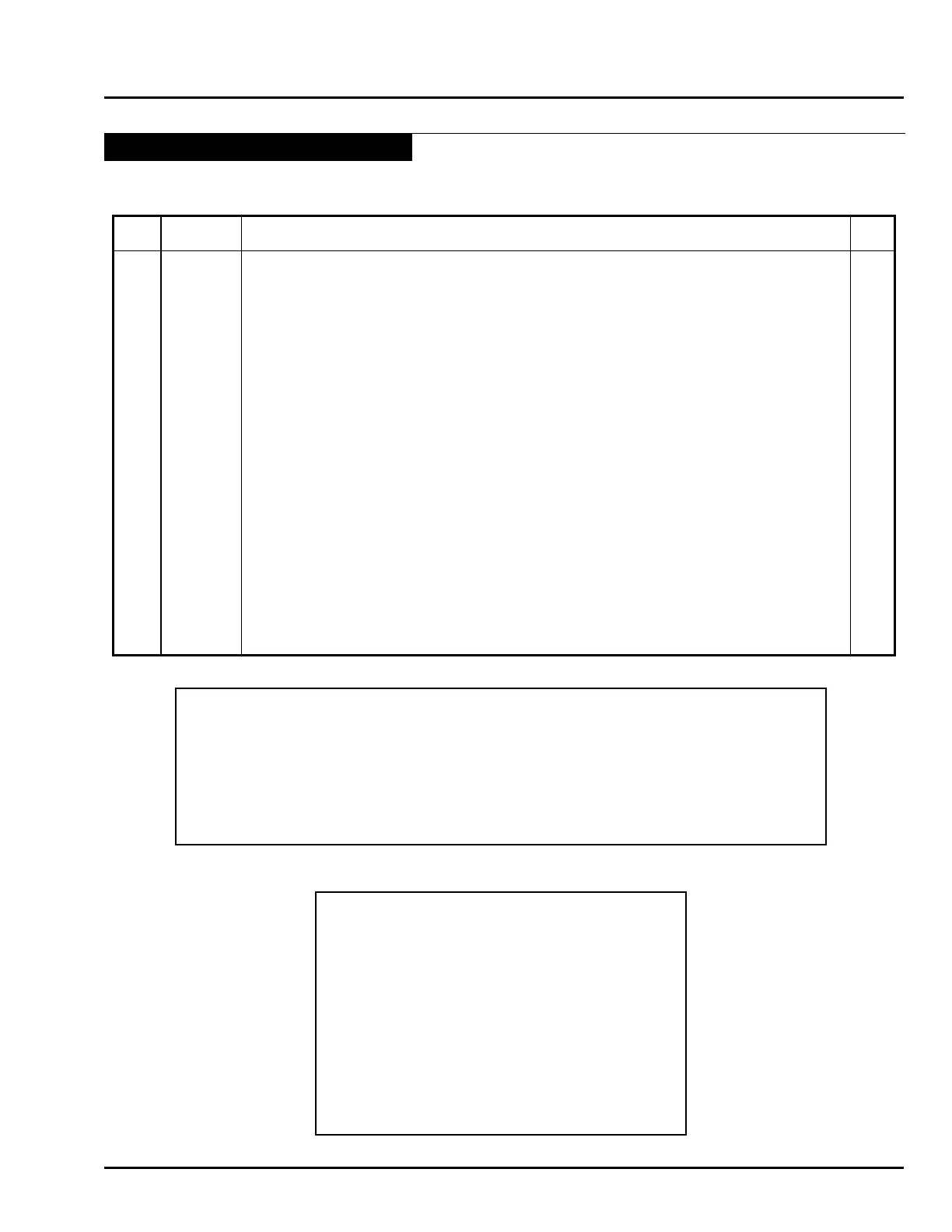

Opener Maintenance - Continued

Opener Body Assembly

Note: Openers should drop to the ground under their own weight, when the tractor

remote is placed into float position relieving oil pressure.

If it requires pressure to push an opener down to the ground during this

procedure, one or more of the pivot bolts are over tightened.

Check and adjust pivot bolts as required.

Loading...

Loading...