TECHNICAL MANUAL

Chapter 10 - Length shut-downs

NGSi 05÷15

39

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

CHAPTER 10

LENGTH SHUT-DOWNS

• Turn off the units by turning the switch of each device to “OFF”.

• Turn off the water taps.

• Turn the master switch to “OFF”.

CHAPTER 11

ROUTINE CHECKS AND MAINTENANCE

Regular inspections should be performed to ensure that the unit is operating correctly:

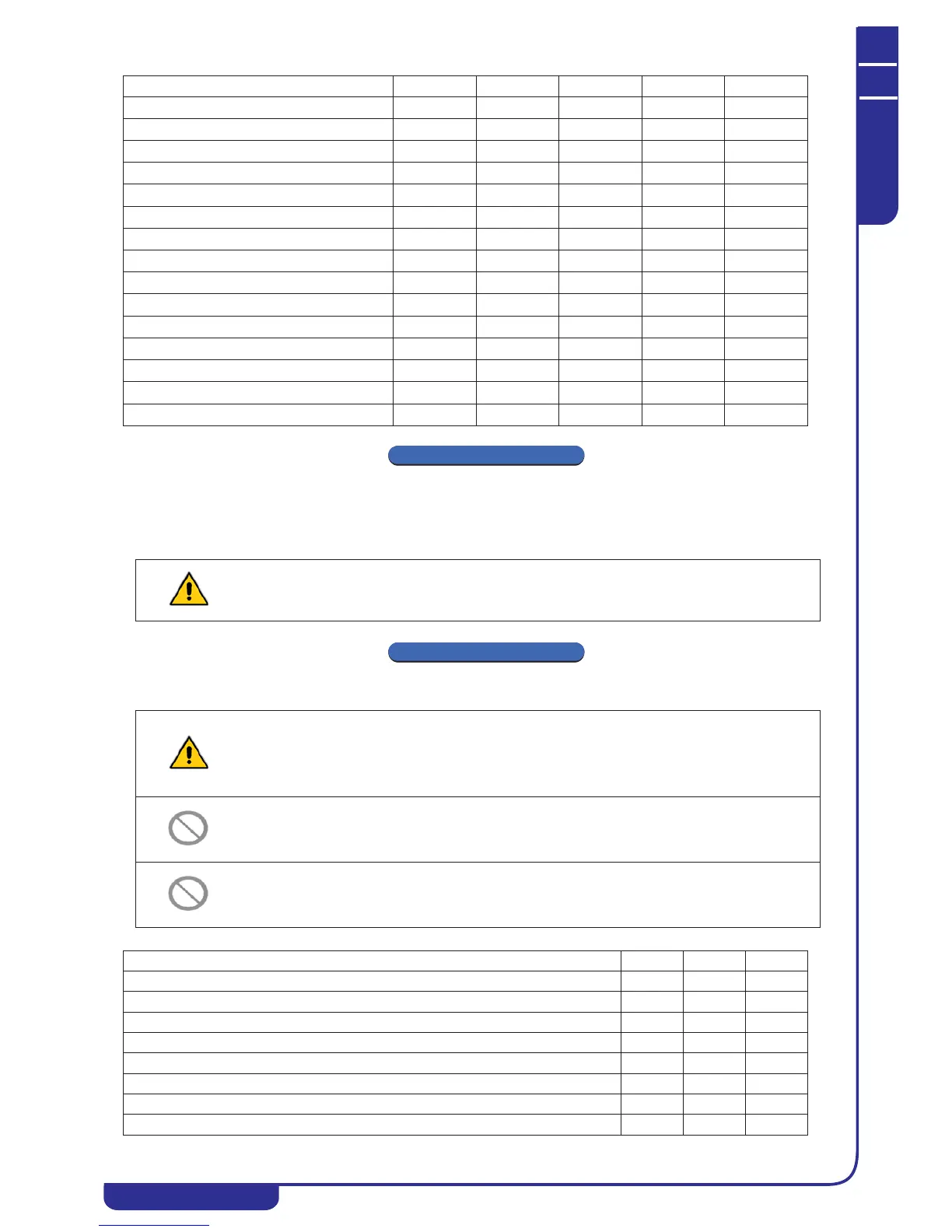

Compressor not connected to power supply E79

OFF OFF

Inverter timeout E80

OFF OFF

Intake water probe E61

OFFOFFOFFOFF

Output water probe E62

OFFOFFOFFOFF

Compressor intake probe E63

OFFOFFOFFOFF

Compressor output probe + high pressure switch E64

OFFOFFOFFOFF

High pressure transducer E65

OFFOFFOFFOFF

Low pressure transducer E66

OFFOFFOFFOFF

External air probe for weather control E67

OFFOFFOFFOFF

Domestic hot water tank probe (optional) E69

OFFOFFOFFOFF

Flow switch E06

OFFOFFOFFOFF

High temperature E18

OFF OFF

High pressure E01

OFF OFF

Low pressure E02

OFF OFF

Anti-freeze alarm E05

OFF ON OFF OFF

If the temperature drops below zero there is a serious risk of freezing: fill the system with a mixture of water and glycol, or

drain the water system and heat pump water circuits.

WARNING:

All the operations described in this section MUST ALWAYS BE PERFORMED BY QUALIFIED STAFF. Before doing any

work on the unit or accessing internal parts, make sure that the electricity supply has been disconnected. The compressor

heads and delivery pipeline are often at quite high temperatures. Take special care when working in the vicinity of the heat

exchanger coils. The aluminium fans are particularly sharp and may cause serious injuries. After maintenance procedures,

put the panels back in place, securing them with the fixing screws.

The cooling circuits must not be charged with a refrigerant different from the one specified on the nameplate. Use of a

different refrigerant may seriously damage the compressor.

The use of oils other than those specified in this manual is forbidden. Use of a different oil may seriously damage the

compressor.

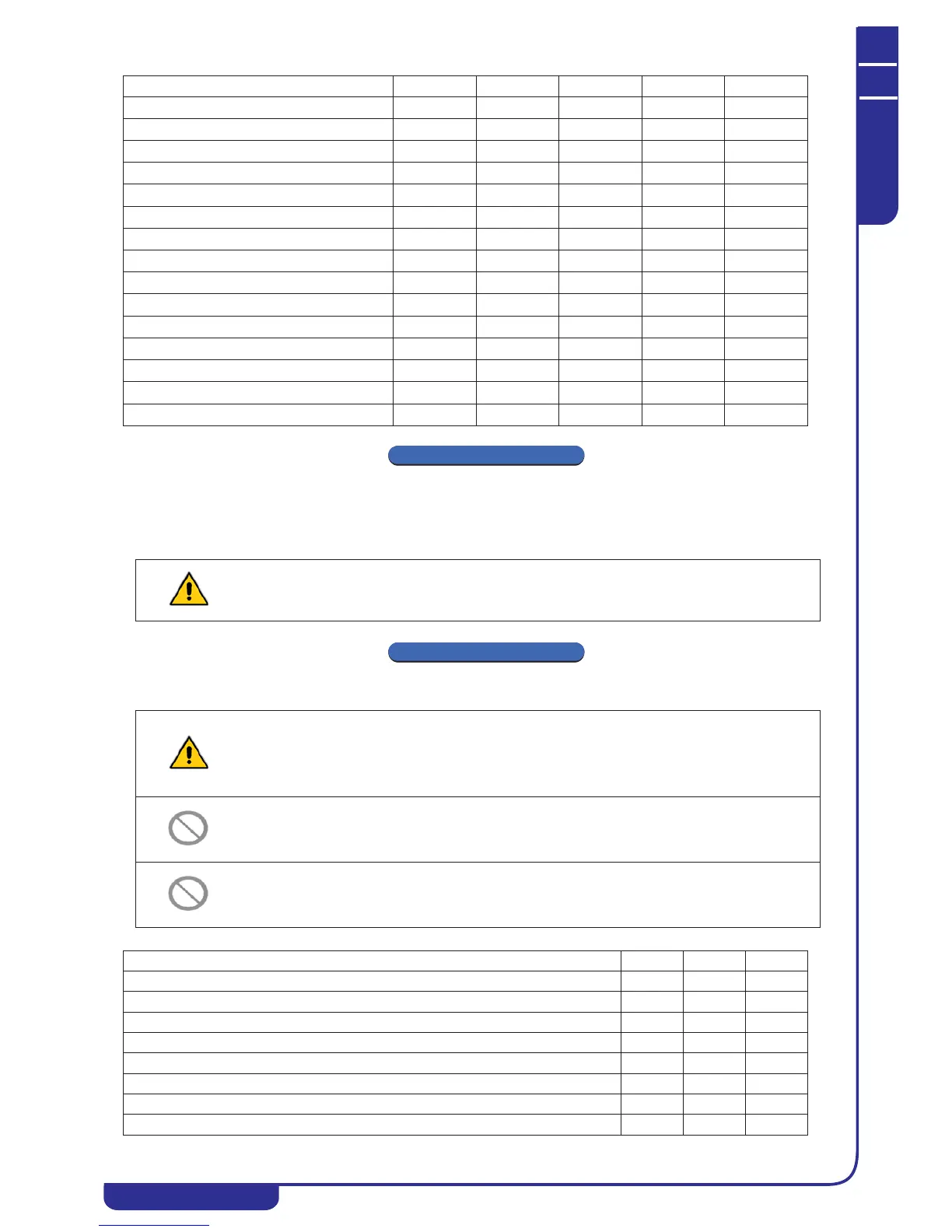

OPERATION 1 month 4 months 6 months

Filling of water circuit. x

Presence of bubbles in water circuit. x

Check that monitoring and safety devices are operating correctly. x

Check that there are no oil leaks from the compressor. x

Check that there are no water leaks in the water circuit. x

Check that the flow switch is operating correctly. x

Check that the crankcase heaters are powered up and operational. x

Clean the metal filters in the water circuit. x

Type of failure Code Compressor Pump Heaters Fan

Loading...

Loading...