TECHNICAL MANUAL

Chapter 12 - Taking the unit out of service

NGSi 05÷15

40

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

11.1 Environmental protection

The law regulating the use of ozone-depleting substances forbids the discharge of refrigerant gases into the environment. They must be

recovered and returned to the disposal centres provided at the end of their useful life. R410A is one of the refrigerants subjected to specific

control mechanisms enforced by law and its users must therefore comply with the requirements set out above. Special care must therefore be

taken during maintenance, to minimise any refrigerant leaks.

CHAPTER 12

TAKING THE UNIT OUT OF SERVICE

A number of recommendations must be followed when the unit reaches the end of its working life and therefore needs to be replaced:

• the refrigerant must be recovered by specialist staff and sent to the disposal centres;

• the compressor lubricating oil must also be recovered and sent to the disposal centres;

• if they are not usable, the structure and the various components must be dismantled and subdivided by type, especially the

copper and aluminium, of which the unit contains fairly large amounts.

These procedures facilitate the recovery and recycling of the substances concerned, thus reducing environmental impact.

CHAPTER 13

TECHNICAL DATA

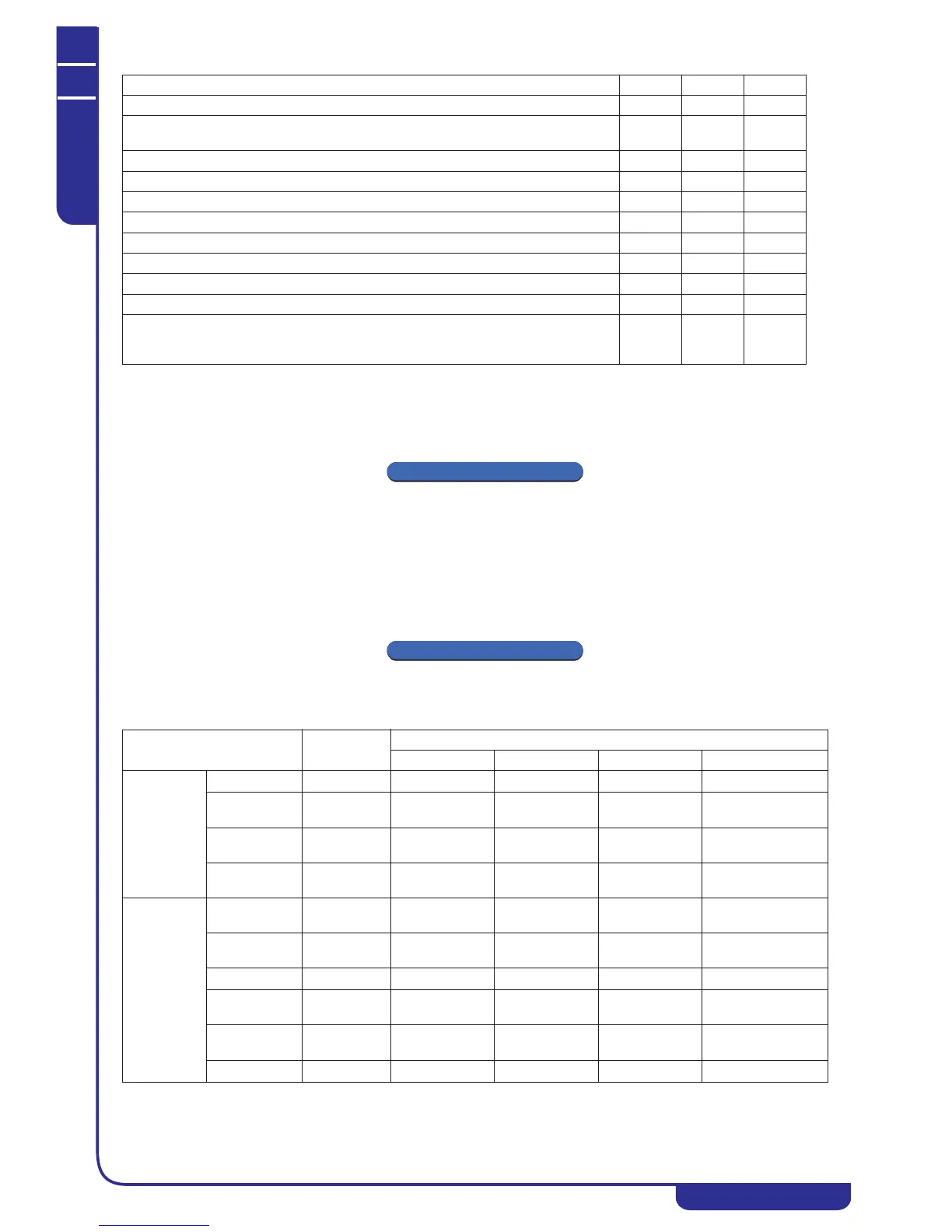

Clean the finned coil exchangers using compressed air or a jet of water. x

Check that the electric terminals inside both the control panel and the compressor terminal boards

are securely fixed.

x

Tightness of water connections. x

Check that the fans are well fixed and balanced. x

Correct electrical voltage. x

Correct power drawdown. x

Check on the charge of refrigerant. x

Check on working pressure, overheating and under-cooling. x

Operation of circulator pump. x

Check on expansion vessel. x

If the unit is to be out of use for a long time, drain the water from the pipelines and heat

exchanger. This is essential if room temperatures below the freezing point of the fluid used are

expected during the lay-off.

x

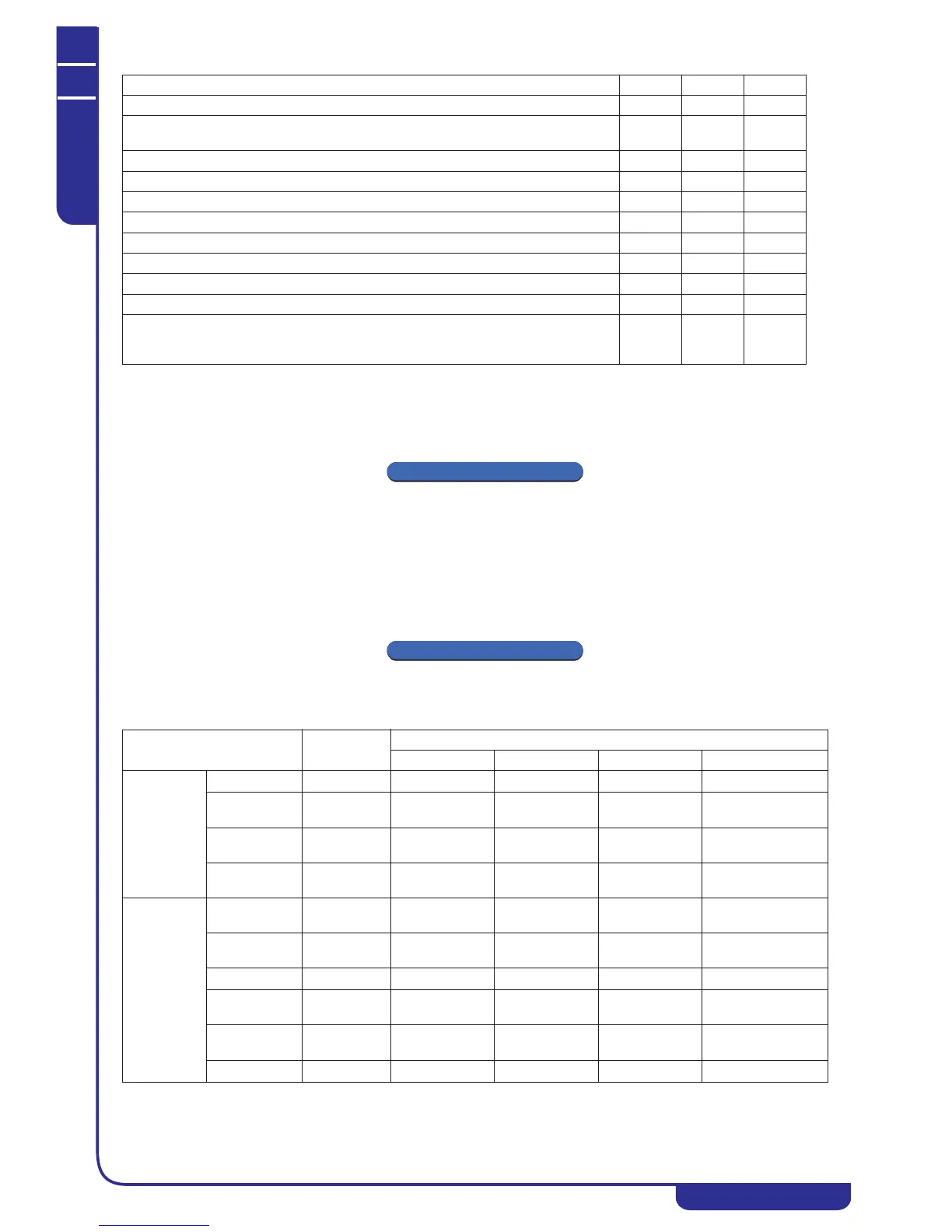

Technical features

Unit of

measurement

Model

NGSi 05 NGSi 07 NGSi 10 NGSi 15

Electrical data

Power supply

230V/1/50Hz 230V/1/50Hz 230V/1/50Hz 400V/3+N+PE/50Hz

Max. power

drawdown

kW 2.81 4.61 5.78 7.93

Maximum

starting current

A 7.9 13.0 16.4 7.5

Maximum current

drawdown

A 12.3 20.2 25.4 11.5

Cooling

Cooling capacity

(1)

kW 4.13 6.49 8.20 10.51

Power drawdown

(1)

kW 1.33 2.08 2.65 3.39

E.E.R. (1)

W/W 3.11 3.12 3.10 3.10

Cooling capacity

(2)

kW 5.72 8.93 12.36 14.00

Power drawdown

(2)

kW 1.44 2.27 2.98 3.64

E.E.R. (2)

W/W 3.98 3.93 4.15 3.85

OPERATION 1 month 4 months 6 months

Loading...

Loading...