IGNITION SYSTEM

49

Troubleshooting the ignition system

The purpose of the ignition system is to provide a

spark in the combustion chamber at the proper time to

ignite the fuel/air mixture. The steps in troubleshooting

the ignition system are:

1. Examine the spark plug(s) by following the steps

described in the spark plug section of this chap

-

ter.

NOTE: It is convenient to check the compres-

sion when the spark plug is removed for exami-

nation.

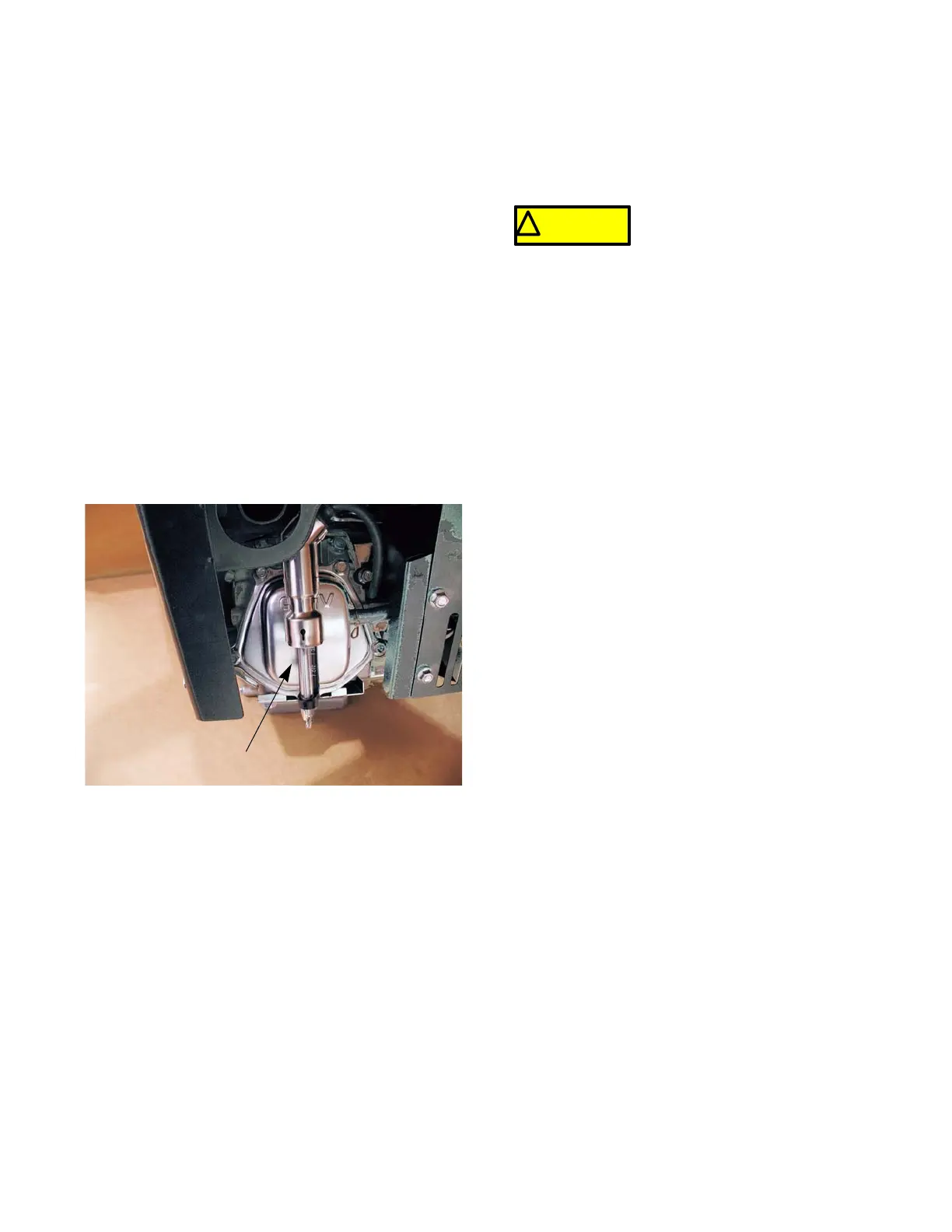

2. Connect a spark tester between the spark plug

wire and a good ground point on the engine.

See Figure 7.1.

Figure 7.1

Spark tester

NOTE: It only takes 1,000 volts to jump a .025”

air gap in open atmosphere, it takes 10,000 volts

to jump the same gap at 120 psi; therefore, an

open air spark test in not valid.

NOTE: The spark should be a minimum of 10 Kv

(10,000 volts) at pull over speed.

3. Insert key and move throttle to the full throttle

position.

4. Pull the starter rope. If sparks can be seen in the

spark tester, the ignition system is working.

NOTE: If there are sparks present in the spark

tester, install a known-good spark plug and

prime test the engine. If the engine does not

start, check the fly wheel key. If the fly wheel key

is intact, the problem is not in the ignition sys

-

tem. Check the engine’s compression.

5. If no sparks or weak sparks are seen in the

spark tester, use the electric starter to spin the

engine.

NOTE: If sparks are now seen in the spark

tester, check the module air gap. If no sparks are

seen, further testing is required.

6. Test the stop switch by following the steps

described in the stop switch section of this chap

-

ter.

7. If the stop switch is working properly, inspect the

flywheel and flywheel key. If the flywheel and

key are OK, replace the module.

! CAUTION! CAUTION

Never remove the spark plug and

hold it against the cylinder head to

test for spark. The fuel/air mix

coming out of the spark plug hole

will catch on fire.

CHAPTER 7: IGNITION SYSTEM

Loading...

Loading...