THE FUEL SYSTEM AND GOVERNOR

26

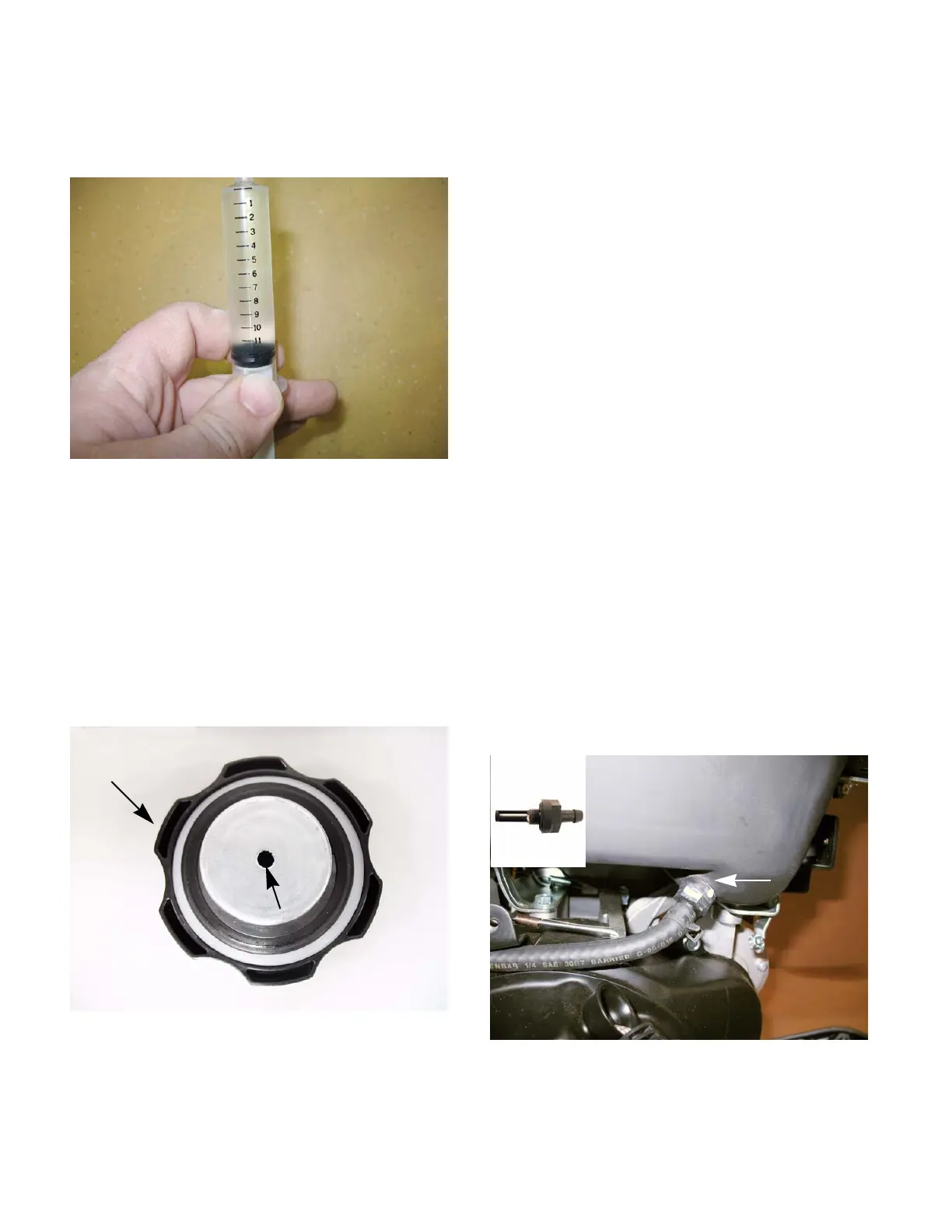

Generally these kits involve mixing a measured

amount of water and gas together and seeing were the

boundary layer is.

See Figure 4.2.

The test kit should come with a chart to compare

the boundary layer height to alcohol percentage.

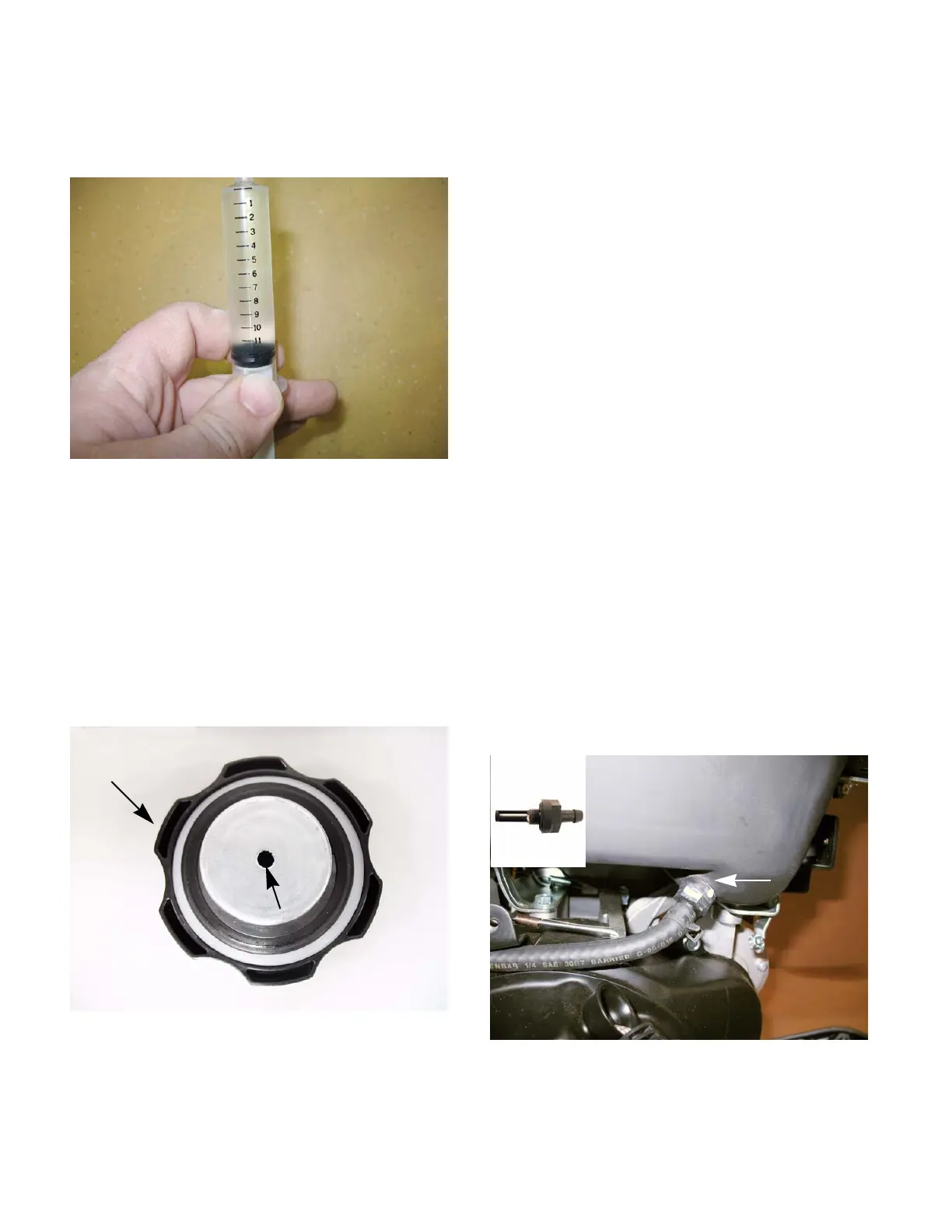

Fuel tank vent

The fuel tank vent performs the important task of

allowing air into the fuel tank. As fuel is being used by

the engine, the fuel level in the tank drops. The drop

-

ping fuel level then creates a vacuum in the tank. If the

fuel tank could not draw air through the vent, the vac

-

uum would prevent the fuel from getting to the carbure-

tor. The vent is located in the fuel cap. See Figure 4.3.

To test the cap vent

1. Remove the fuel cap.

2. Clean off the vent.

3. Blow air into the vent hole. The air should blow

throw the vent with little back pressure.

4. Suck air through the vent hole. Air should freely

enter through the vent.

• Replace the cap if the vent builds pressure or

restricts air movement.

• A cap that maintains pressure will cause the

engine to run rich as the fuel in the tank heats

and expands, forcing it’s way past the float valve

in the carburetor.

• A cap that maintains vacuum will cause the

engine to run lean as the fuel is depleted and no

air comes in to replace it.

• The two conditions may both be present, but the

symptoms vary with fuel, fuel level, and operat-

ing conditions.

• A bad fuel cap vent usually presents as a “Runs

and quits” scenario.

The fuel filter

The fuel filter is located in the fuel tank nipple. It

can be removed and cleaned with a can of carb cleaner

or it can be replaced.

See Figure 4.4.

NOTE: If cleaning a filter, back-flush it by spray-

ing the carb cleaner through the barb end and

out of the screen. Also make sure the fuel tank is

clean.

To replace the fuel filter follow the steps described

in Chapter 1: Introduction.

Figure 4.2

Figure 4.3

Fuel cap

Vent

Figure 4.4

Filter

nse

:

Fuel filter/barb

Loading...

Loading...