STARTER AND CHARGING SYSTEMS

42

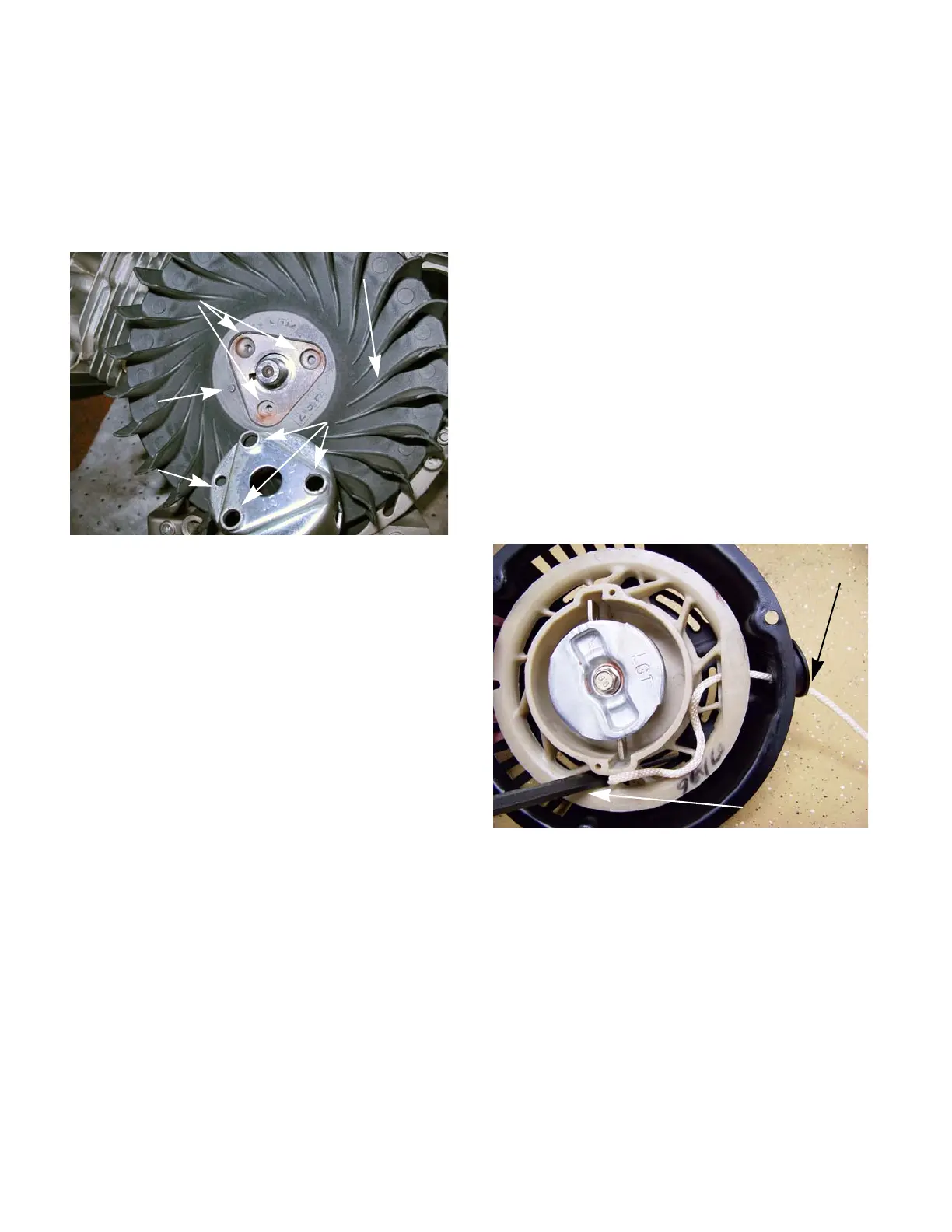

4. Install a starter cup:

• Place the starter cup on the flywheel, with the

three dimples on the bottom of the starter cup

into the dimples in the flywheel

• Align the pin on the flywheel fan with the hole in

the starter cup. See Figure 6.3.

5. Install the flywheel nut and tighten it to a torque

of 47 - 52 ft-lbs (64 - 70 Nm).

Starter Rope

The most common failure mode for most recoil

assemblies is a broken rope.

NOTE: If the spring was not damaged when the

recoil sprung back, it is possible to simply

remove the remnants of the old rope and install

a new rope.

1. Remove the starter by following the steps

described earlier in this chapter.

2. Remove the old starter rope by prying out the

starter cord knot and pulling the rope out with it.

3. Cut a piece of #6 recoil rope 75” (1.9 meters)

long.

4. Heat fuse the ends of the starter rope, and tie a

double half-hitch in one end.

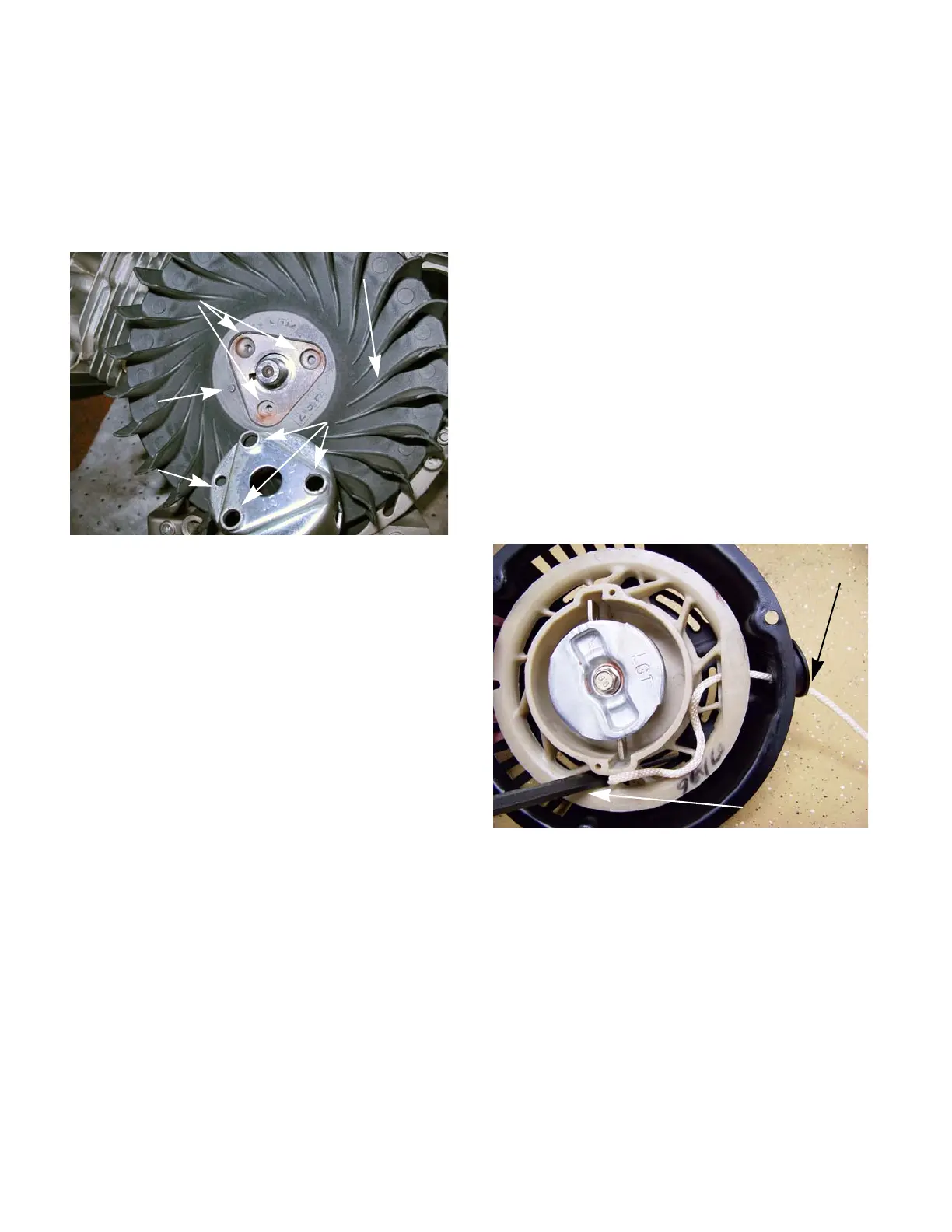

5. The rope may be easily installed from the out-

side-in. Pull the rope tight to seat the knot firmly

in the recess in the back of the pulley.

See Figure 6.4.

NOTE: It may be necessary to wind the pulley

clockwise to line up the hole in the pulley to the

hole in the starter housing. If so, use a punch or

screwdriver to block the pulley, preventing it from

rewinding.

See Figure 6.4.

6. Wind the spring 6 - 7 turns and block it with a

punch or screwdriver to keep it from rewinding.

Figure 6.3

Flywheel dimples

Starter cup

Alignment pin

Alignment hole

dimples

Figure 6.4

Rope inserted

from the inside

out

pulley blocked

Loading...

Loading...