STARTER AND CHARGING SYSTEMS

43

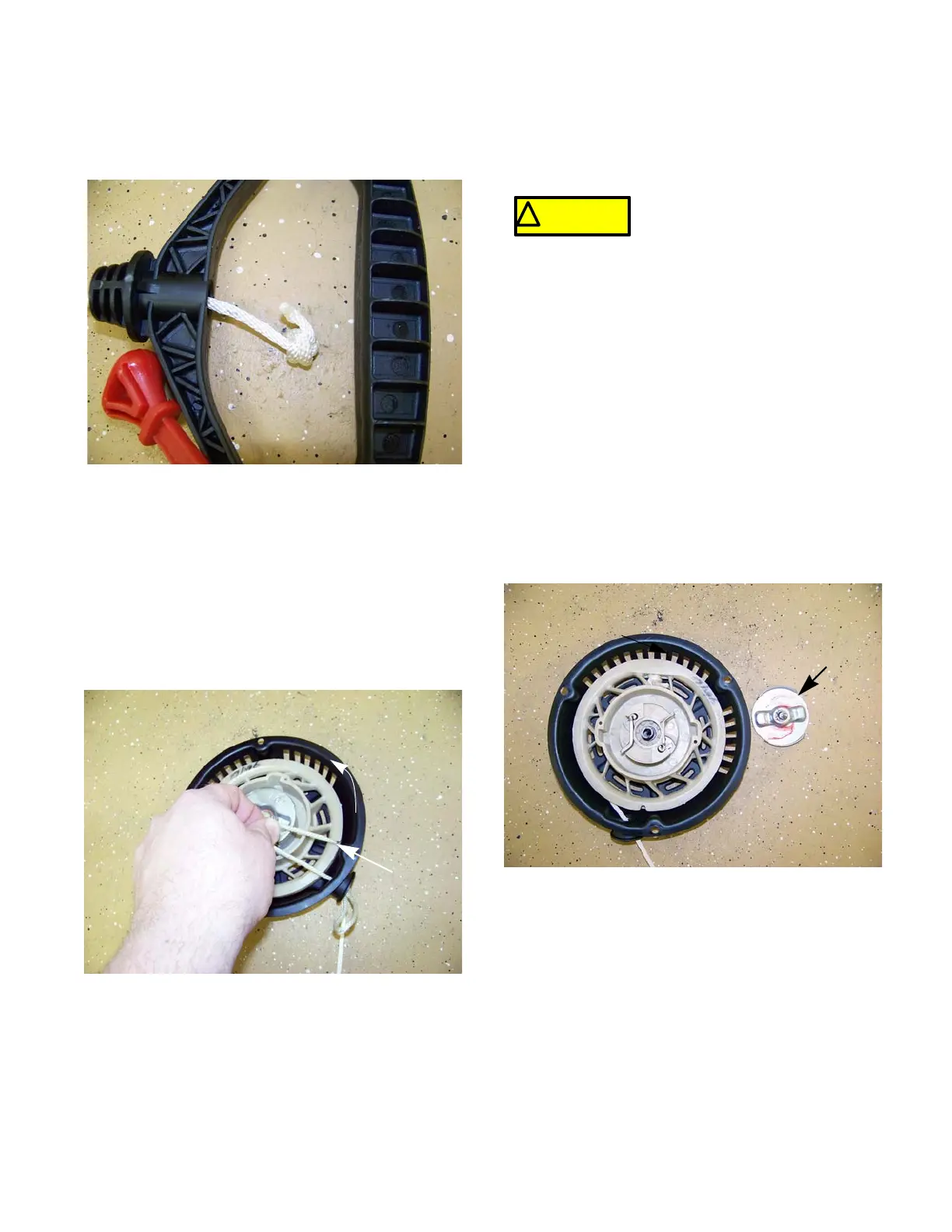

7. Install the handle and handle insert on the loose

end of the rope, again using a double half-hitch.

See Figure 6.5.

8. Remove the blocking tool and at a controlled

rate, let the rope rewind into the starter.

9. Give the starter a couple of test pulls to verify the

right amount of tension on the starter rope.

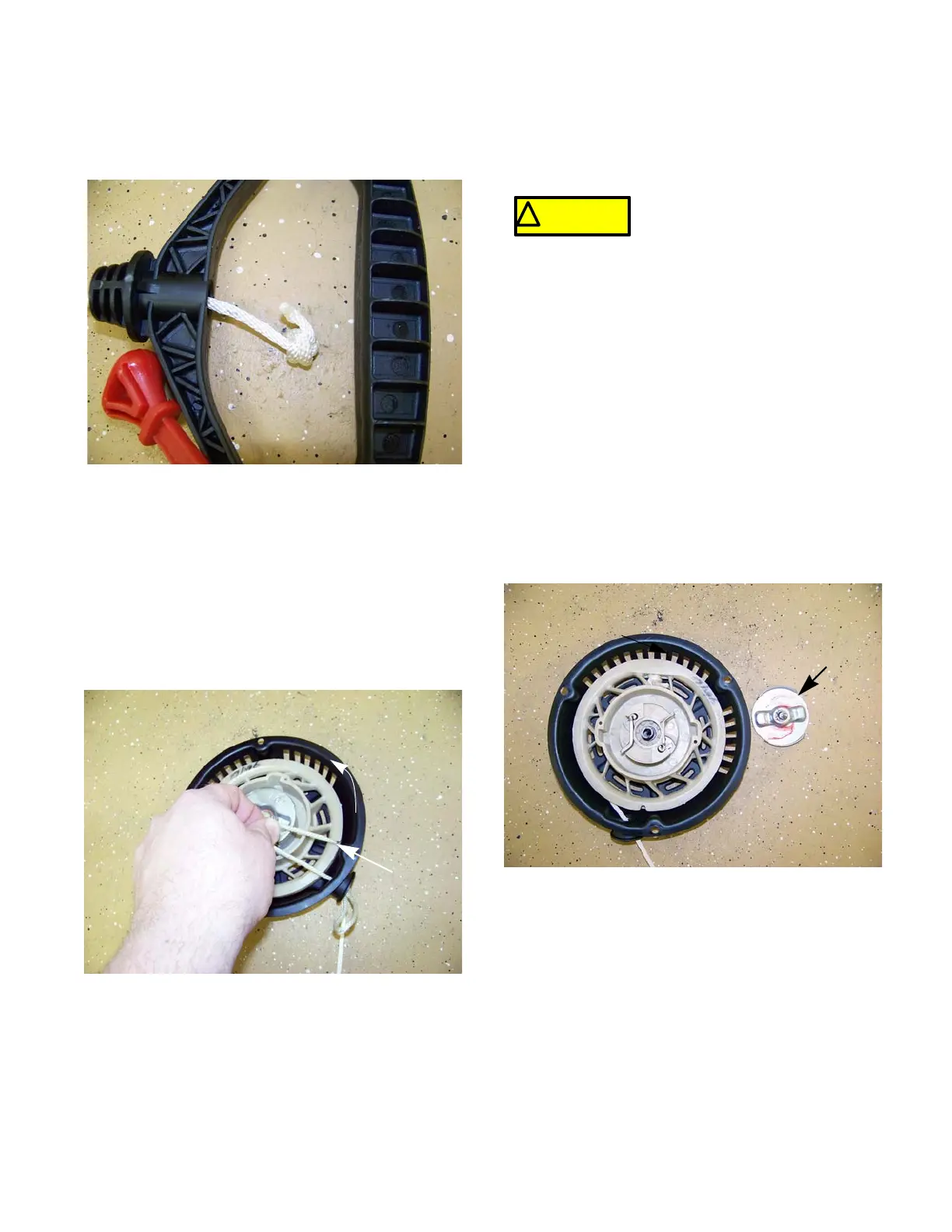

NOTE: If starter rope tension needs to be

adjusted, hook the rope into the notch in the pul

-

ley and wind the pulley a couple of turns to add

tension-.

See Figure 6.6.

10. Install the starter and tighten the starter nuts to a

torque of 53 - 71 in-lbs (6-8 Nm).

Figure 6.5

Figure 6.6

Rope-return tension may be increased by winding

the rope and pulley counter clockwise.

notch in pulley

Starter pulley and recoil spring

The recoil spring is nested within the starter pulley

and both parts are sold as a single part number.

If damage is suspected, the recoil may be disas-

sembled by:

1. Remove the starter by following the steps

described earlier in this chapter.

2. Relieve the spring tension by:

2a. Pull some slack in the rope, inside of the

starter

2b. Hook the rope into the notch in the starter

pulley.

2c. Wind the pulley clockwise until all tension is

removed.

3. Remove the shoulder screw and pressure plate

using a 10 mm wrench.

See Figure 6.7.

NOTE: Beneath the pressure plate is a com-

pression spring and two starter pawls that are

held in the disengaged position by two torsion

springs.

! CAUTION! CAUTION

Eye protection should be worn if

the starter pulley is to be removed.

Figure 6.7

Pressure plate

Loading...

Loading...