FAILURE ANALYSIS

84

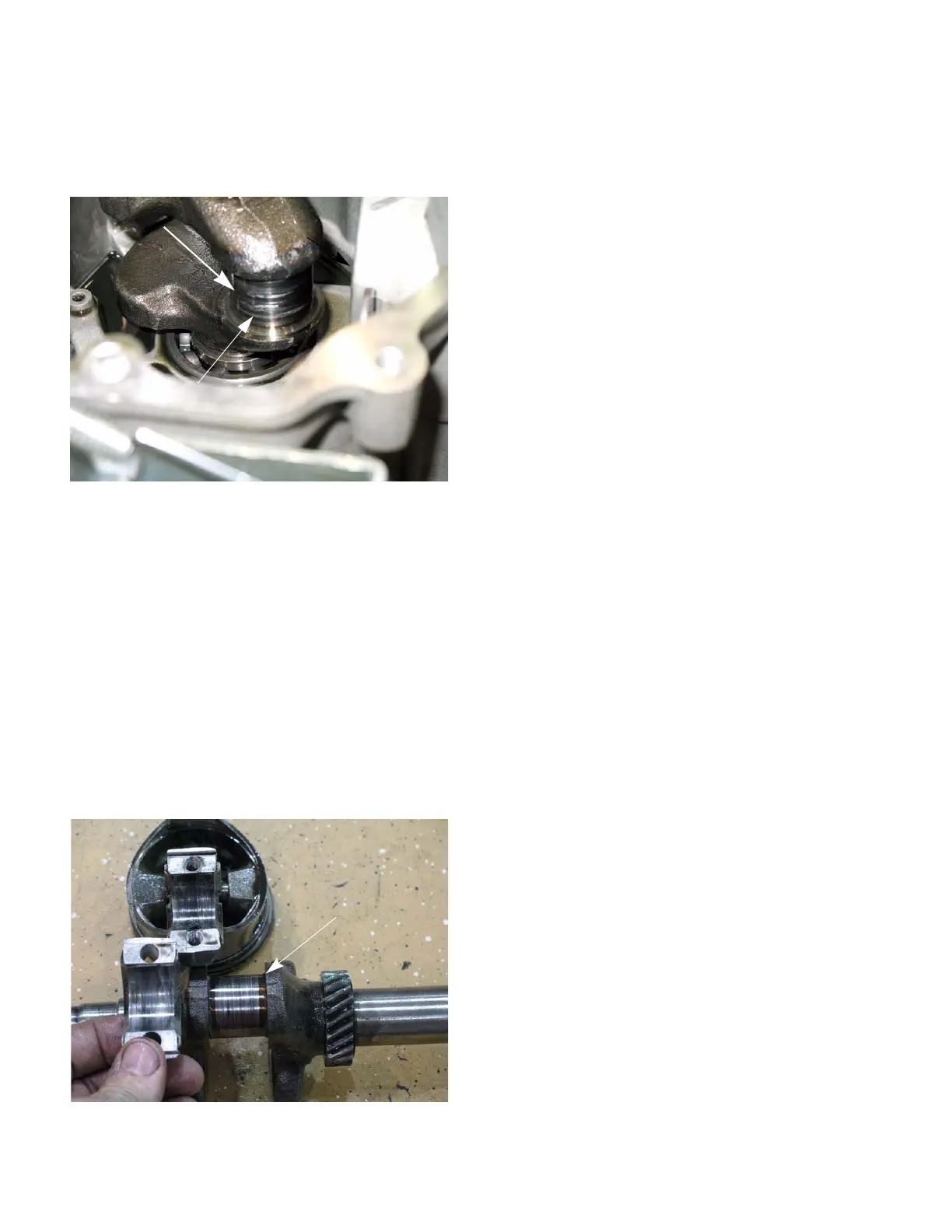

The hall mark of a lubrication failure is the pres-

ence of discoloration and/or metal transfer on all

friction surfaces within the engine.

See Figure 11.7.

An important thing to note is that just because

there are signs of insufficient lubrication, that does not

mean that was the cause of the failure. It may only be a

symptom of the real cause of the failure.

Larger size abrasive particles can render the lubri-

cants ineffective, leading to an engine failure. An over-

heated engine can cause the oil to break down leading

to a failure. In an engine overspeed, the oil is pushed

away from the bearing surface leading to a failure.

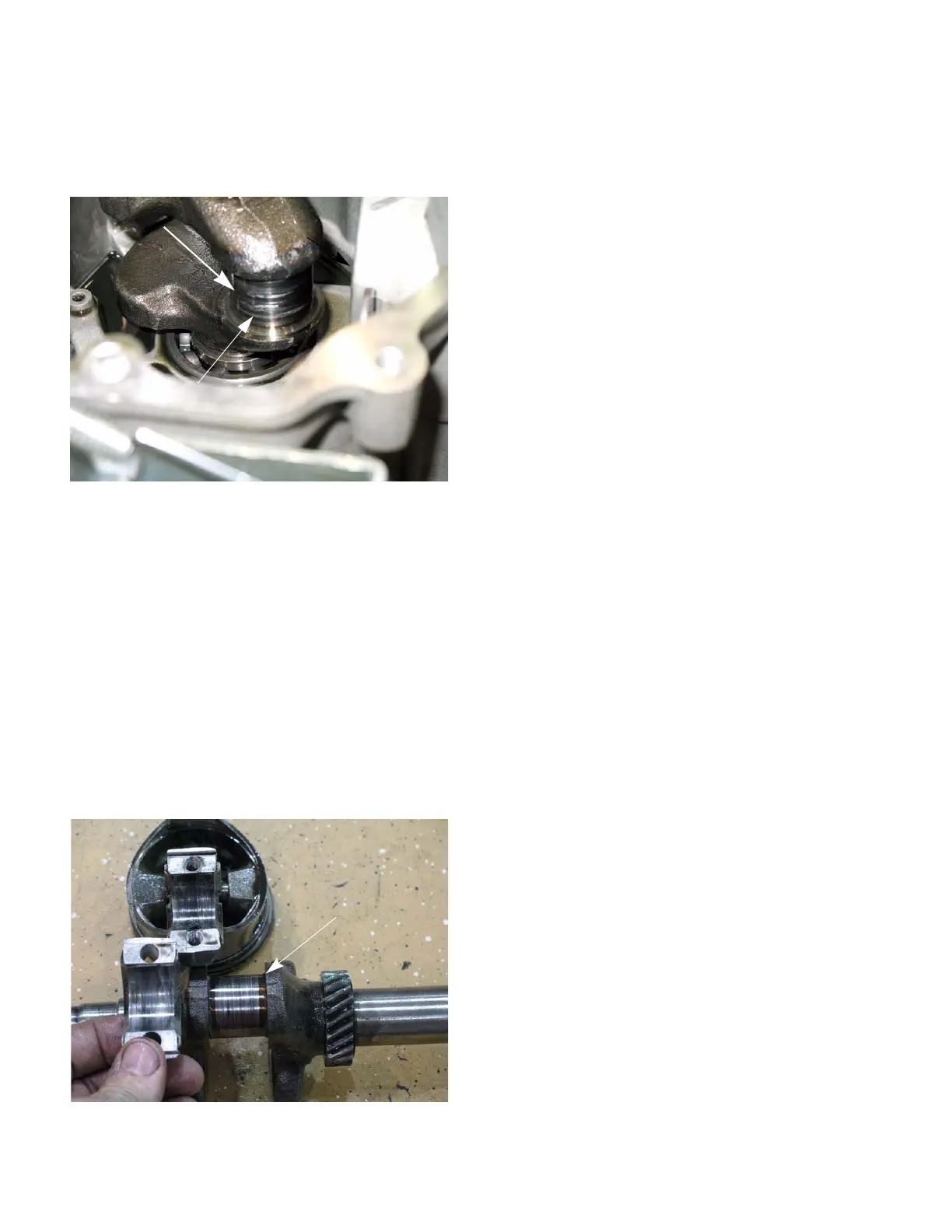

In all three of the above cases, the signs of insuffi-

cient lubrication are symptoms not the cause. There

will also be signs of heat or discoloration around the

parts affected by the lack of lubrication.

See Figure 11.8.

Engine Overspeed

The MTD engine is designed for a maximum speed

of 3600 rpm. When the governor is unable to control

the engine rpm, the engine can accelerate past the

safe maximum speed.

When an engine runs beyond its designed speed,

a few things happen:

1. As the piston moves up and down in the cylinder,

it builds momentum. The higher the rpm’s the

more momentum produced by the pistons. As

the momentum builds, the connecting rods will

start to stretch. When the connecting rods

stretch, they get weaker. Generally speaking this

is at the narrowest part of the connecting rods.

On most engines that would be about an inch

below the wrist pin, but on the MTD engine it is

at the wrist pin.

The force on the connecting rod is greatest

when the piston transitions from the upward

stroke to the downward stroke. Because of this,

most overspeed connecting rod failures will

occur with the piston at top dead center.

When a connecting rod fails, the piston stops

moving but the crankshaft is still moving. This

will allow the broken connecting rod to get

knocked around in the cylinder causing more

damage to it. Usually the connecting rod will be

in several pieces after it breaks making it hard to

find where the first failure was.

2. All engines have vibrations and are designed to

handle those vibrations, but in overspeed the

vibrations change resonance. Parts that can not

handle the new resonance will crack. This may

result in parts flying off of the engine which is an

unsafe condition such as when a flywheel shat

-

ters pieces of it fly off of the engine..

The vibration can also lead to fasteners loosen-

ing up. Evidence of this could be elongated

mounting holes. The area around the mounting

holes may be polished due to the two surfaces

rubbing against each other.

3. When an engine overspeeds, the moving parts

can not pull the oil in between them. This allows

metal to metal contact. Because of this, signs of

inadequate lubrication will show.

4. When trying to diagnose an overspeed failure,

look at all the pieces. Individually the lack of

lubrication, piston position and condition of the

connection rod will usually indicate separate fail

-

ures. Collectively they would indicate an over-

speed failure.

Figure 11.7

Metal to metal

transfer

Discoloration

Figure 11.8

Discoloration

Loading...

Loading...