Chapter 10: Crankshaft, piston and Connecting Rod

94

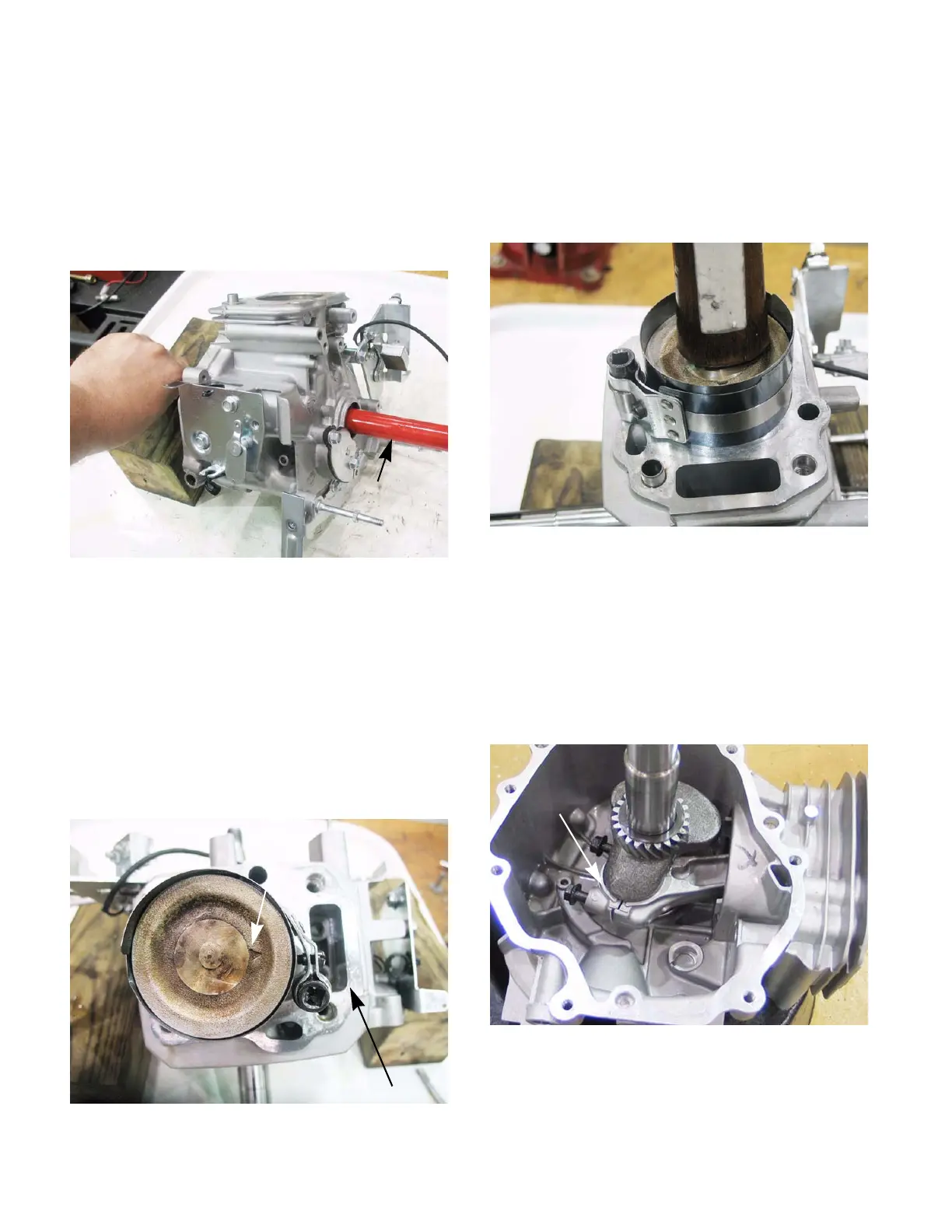

3. Insert the crankshaft into the cylinder block bear-

ing.

NOTE: Pre-lube the crank shaft with clean 10W-

30 motor oil or engine assembly lube.

NOTE: Use an old piece of microfiche or a seal

protector to protect the oil seal lip while inserting

the crank shaft. See Figure 10.22.

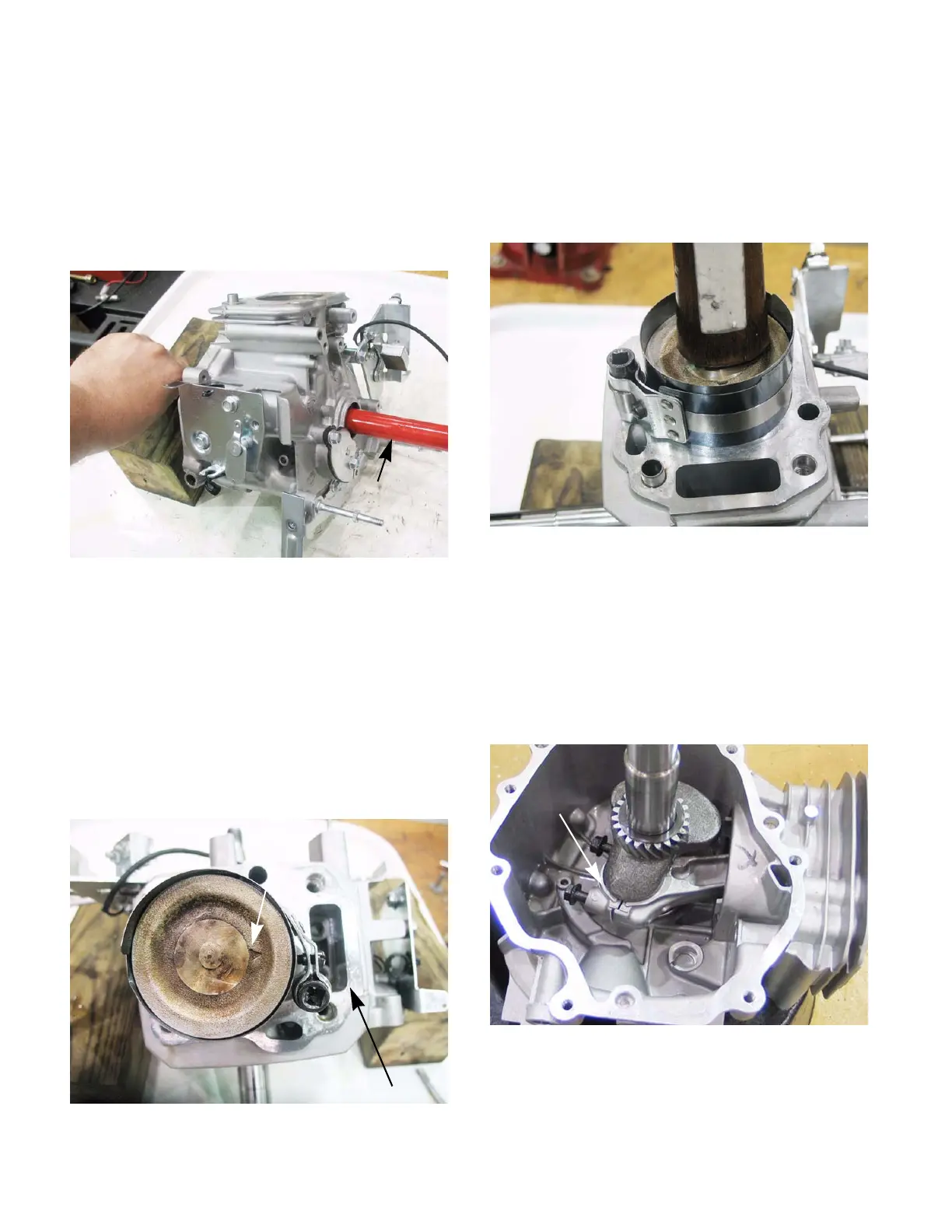

4. Install the piston by:

4a. Compress the piston rings using a piston

ring compressor.

4b. Pre-lube the cylinder wall with clean 10W-30

motor oil

4c. Slide the connecting rod and piston into the

cylinder.

NOTE: The arrow on the piston must point

towards the push rod cavity. See Figure 10.23.

4d. Tap the piston through the ring compressor

into the cylinder using a wooden hammer

handle. See Figure 10.24.

NOTE: Make sure the crankshaft journal is at

BDC (bottom dead center) to prevent damage

from the connecting rod.

4e. Pre-lube the connecting rod with clean 10W-

30 motor oil or engine assembly lube.

4f. Install the connecting rod cap. Apply a small

amount of releasable thread locking com-

pound such as Loctite® 242 (blue) to the

connecting rod bolts and tighten the cap

bolts to a torque of 102 - 111 in-lbs (11.5 -

12.5 Nm). See Figure 10.25.

Figure 10.22

Seal

protector

Figure 10.23

arrow

push rod

cavity

Figure 10.24

Tap piston with

hammer

handle

Figure 10.25

Install the

connecting rod

cap

www.mymowerparts.com

For Discount White Outdoor Parts Call 606-678-9623 or 606-561-4983

Loading...

Loading...