Chapter 7: Ignition System

76

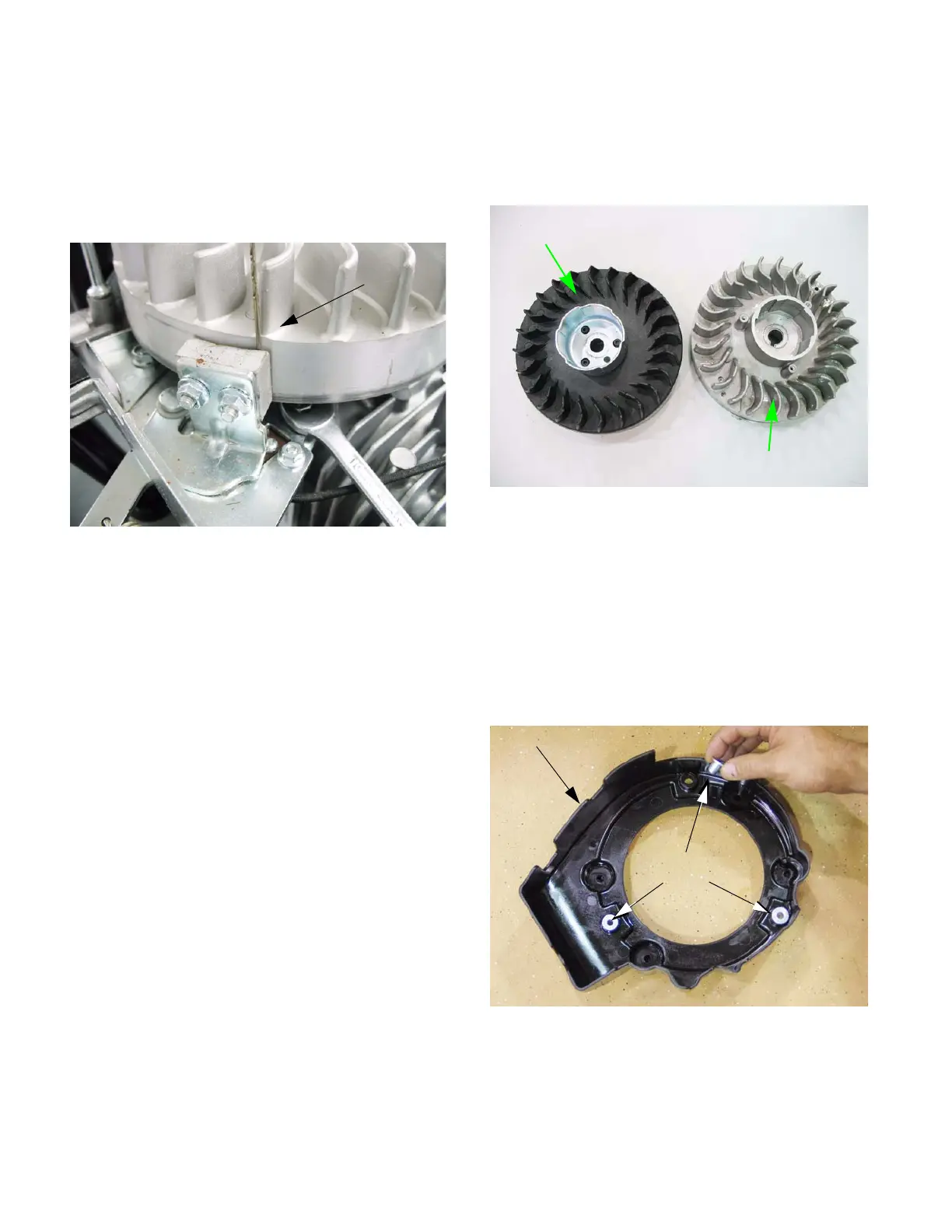

5. Position the brake assembly so that the edge of

the brake pad that is nearest the slotted hole is

roughly .050” (1.27mm) from the flywheel, then

tighten the screws. See Figure 7.21.

NOTE: The shank of an unused drill bit may be

used as a feeler gauge

6. Tighten the two bolts that hold the brake assem-

bly in place.

Flywheel

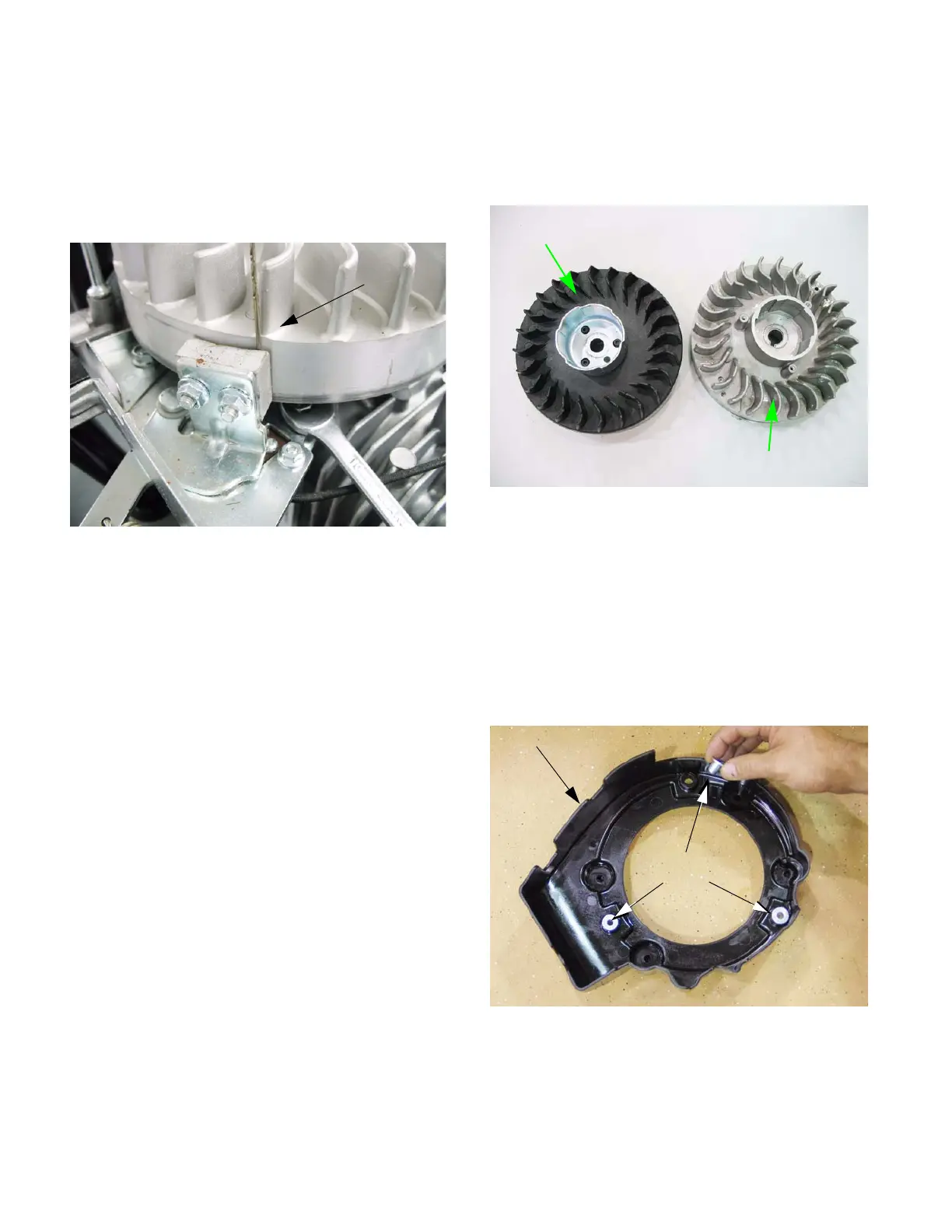

There are two types of flywheels available for the MTD

engine. An aluminum flywheel and a 3-piece cast iron

flywheel. See Figure 7.22.

NOTE: The procedure for removing the flywheel

is the same for both aluminum and cast iron fly-

wheels.

To remove the flywheel:

1. Remove the recoil assembly by following the

steps described in Chapter 6: Starter.

2. Lift the fan shroud off of the three studs that

locate it. See Figure 7.23.

Figure 7.21

Drill bit used

for gauge

Figure 7.22

Cast iron flywheel

Aluminum flywheel

Figure 7.23

Fan shroud

Shoulder

bushings

Shoulder

bushings fit

over studs

www.mymowerparts.com

For Discount White Outdoor Parts Call 606-678-9623 or 606-561-4983

Loading...

Loading...