26

Post Compensation: Post compensation is synonymous with ow sharing. This feature allows all of the hydraulic functions to operate

simultaneously during low pump ow scenarios.

Remember that without post compensation, oil takes the path of least resistance. Flow sharing modulates downstream pressures in order

to keep everything operating. During low ow scenarios, all of the functions may reduce their speeds equally, but all functions should stay

operating.

Pre-Compensation: This feature does not allow for ow sharing. Simply put, this feature provides stable Flow as pressure uctuates in a

system. However, during low pump ow scenarios, an output may completely stop since the ow will take the path of least resistance.

Voltage Compensation: This is a method to control the electrical outputs from the controller. Essentially, the controller maintains a constant

voltage at the output on the controller. This is the most cost effective method at controlling a proportional solenoid, however it is not the most

precise method. As the solenoid coil heats, it’s resistance increases which changes the performance of the valve.

Current Compensation: This is another method to control the electrical output from a controller. Although this is a more expensive method,

it is the most precise method. As the coil heats and the resistance changes, the controller allows the output to increase the voltage to

compensate and keep the output current consistent.

Load Sense: Load sensing was developed to improve the efciency of a circuit. All of our manifolds incorporate LS sensing technology. Load

sensing allows the system to build the pressure that the circuit requires, allowing us to draw less horsepower.

Open Center: Open center refers to valve types. Open center valves are used with xed displacement pumps (gear) and allow the ow to

dump back to tank during system bypass. Without a designated passage to tank, the ow would constantly bleed over relief.

Closed Center: Closed center refers to valve types. Closed center valves are used with variable displacement pumps (piston). These valves

do not offer a passage to tank. Instead, the variable displacement pump de-strokes preventing it from generating ow. Keep in mind that the

piston pump destrokes when the LS signal is at 0 PSI.

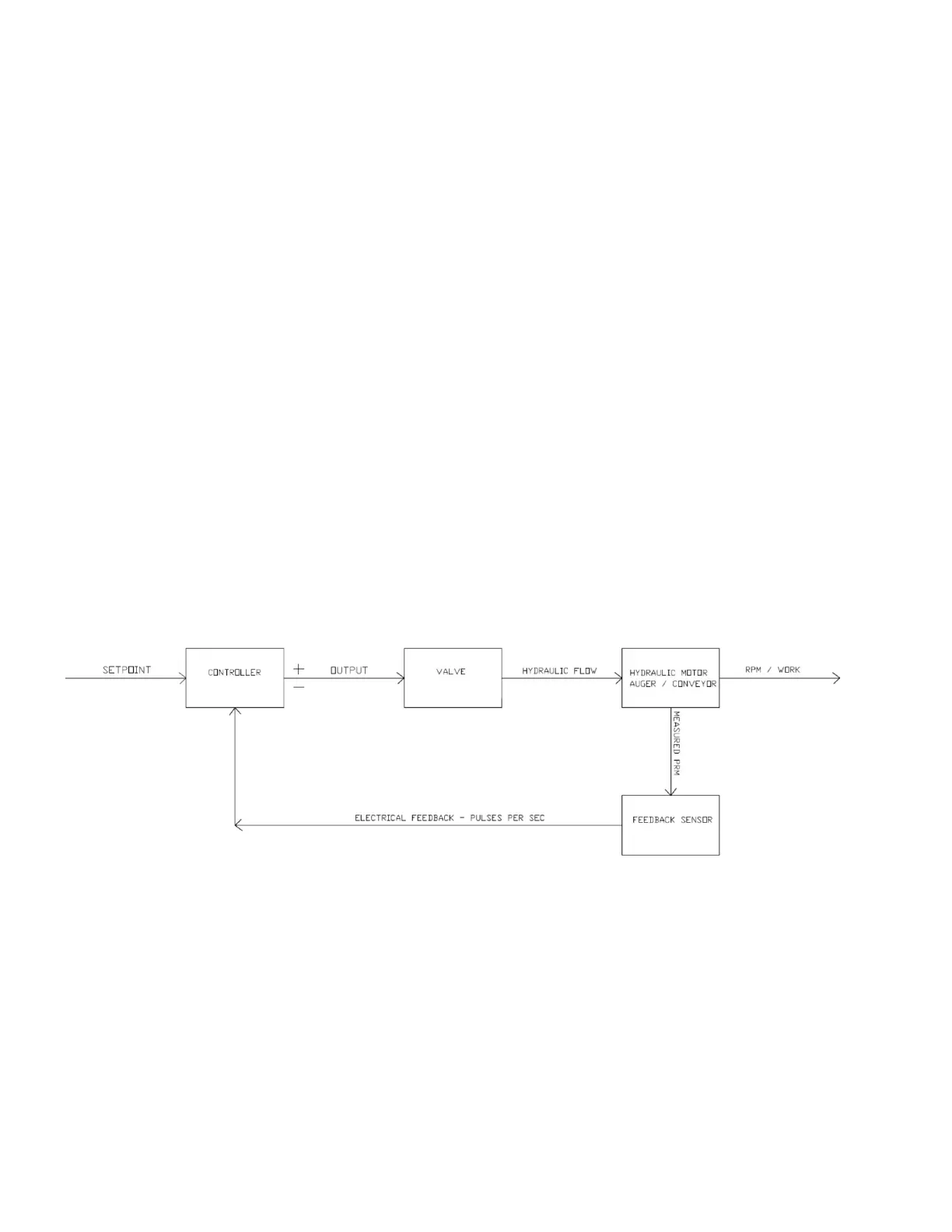

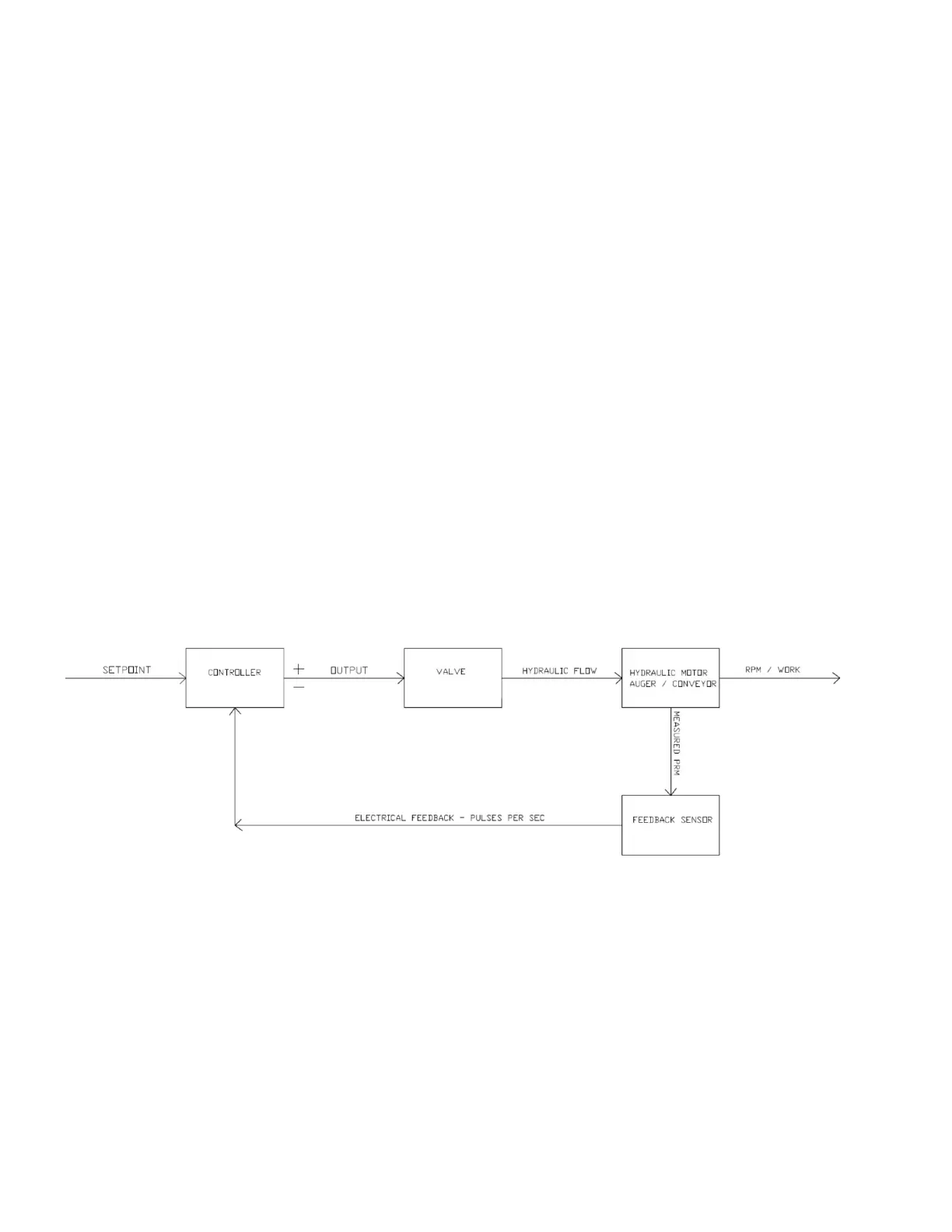

Closed Loop: Closed loop is typically referencing the functionality of the conveyor or pre-wet function. Years before the use of cartridge valves

and current control, closed loop control was required to achieve consistent hydraulic performance. Specically, stack valves have excessive

hysteresis and overshoot.

By placing a feedback sensor on the auger shaft, we can measure how many revolutions per minute the shaft spins. Knowing the RPM, we

can then modulate our current to achieve our desired output. Simply put, if we dial in 200 Lbs. / mile and the valve opens up too much, the

feedback sensor will recognize the inconsistency and readjust the signal to the valve to limit the ow to accomplish the desired setpoint.

Open Loop: Open loop typically refers to the conveyor or pre-wet function. Open loop simply means that electrical feedback isn’t required.

Today with the use of cartridge valves and current control, feedback sensors really aren’t required however they can provide more precision.

The advantage plus has the capability to do either open or closed loop.

Open Circuit Detection: The Advantage Plus Controller has built in diagnostics that detect when a solenoid is unplugged. When this occurs,

the controller will generate an error code on the screen and a button (cylinder function) or display (spreader function) will ash.

Many of our competitors have test lights at the valve to indicate that the electrical connection is connected and ring. However, our buttons

provide real time feedback by turning from green to red to indicate that an output is connected and actuated.

Digital Input – Digital inputs are simply on or off switches that are connected to the system. Digital inputs include oil level oat switches, body

up switches, hot oil switches, cold oil temperature switches, and lter bypass switches.

Analog Input – These are inputs that generate a proportional 0-5 volt signal. In the Advantage Plus, analog inputs include the pressure

transducers that measure the hydraulic pressures.

PWM input – These inputs provide a pulsed signal (either square or sine). Examples of PWM signals include speedometer sensors, IR

temperature sensors, and feedback sensors.

CAN inputs – These are inputs that are connected to out CAN-BUS network. Typically, these will have a power, ground, CAN-Hi, and CAN-Lo

connections. Examples of these connections include: IR temperature sensors.

GLOSSARY OF TERMS

Loading...

Loading...