3–3

5. Do not locate the intake and outlet for the process air too close together. If possible,

allow a distance of at least 5 feet. Allow the same distance between the inlet and

outlet for the reactivation air.

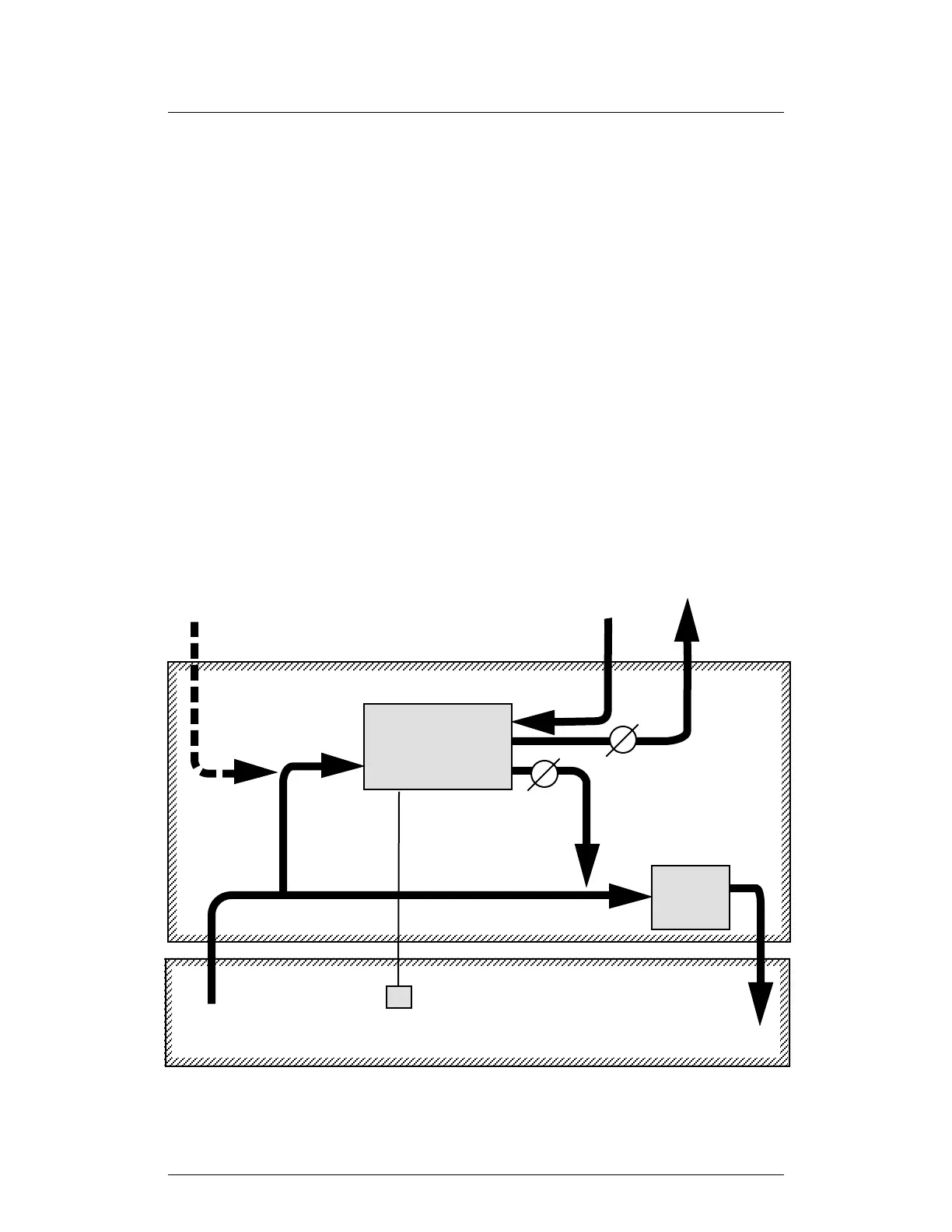

6. Figure 3–3 shows the set-up if you are installing the HC-150 in a system with an

existing air-handling unit. Notice that both sides of the HC-150 are connected

upstream of the air-handling unit.

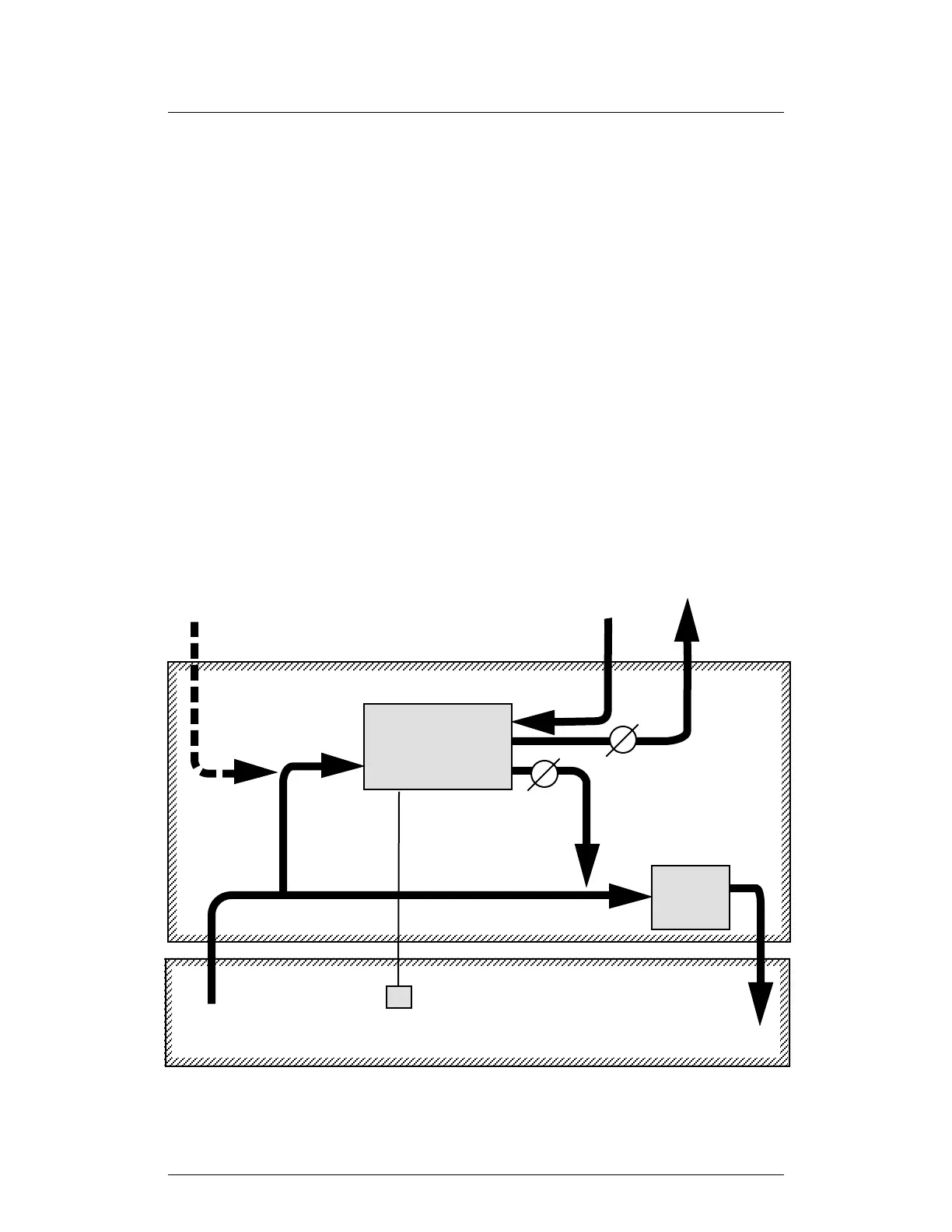

Do not connect the HC-150 so that it bypasses the air-handling unit. See Part A of

Fig. 3–4. If you connect the ductwork this way, some of the air from the air-handling

unit may be forced back through the HC-150, and the HC-150 will not be able to

work correctly.

You may connect both sides of the HC-150 downstream of the air-handling unit, as

shown in Part B of Fig. 3–4. The arrangement shown in Fig. 3–3 is better, however.

This set-up allows the air-handling unit to heat or cool the processed air after it

leaves the HC-150.

7. On some installations, “makeup” air is taken from outside the process space, and

added to the process air stream. Unconditioned makeup air can add a moisture

FIGURE 3–3

HC-150 INSTALLED WITH EXISTING AIR-HANDLING UNIT

Reactivation air IN –

from outdoors

Reactivation air OUT –

to outdoors

Process air

IN

Process air

OUT

Optional makeup air IN –

from outdoors

HUMIDISTAT

(option)

OUTDOORS

PROCESS SPACE (STORAGE AREA)

J138

Damper

Damper

HC-150

DEHUMIDIFIER

Return air IN –

from process space

PROTECTED SPACE

PROTECTED SPACE

AIR

HANDLING

UNIT

Loading...

Loading...