Do you have a question about the Munters HC-300 and is the answer not in the manual?

Explains how the HC-300 removes moisture using the HoneyCombe® wheel and desiccant.

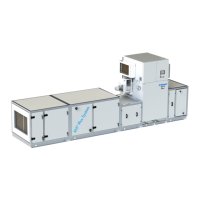

Details the HC-300's components, including the HoneyCombe® wheel, seals, blowers, and sensors.

Describes the unit's control panel, including the Auto/Off/Manual switch, running light, fault light, and time meter.

Explains safety features like temperature switches, fusible links, and motor overload protection.

Instructions for checking the unit for shipping damage and verifying component installation upon arrival.

Details required clearances around the unit for proper operation and access.

Guidelines for connecting process and reactivation air ductwork, including placement and insulation.

Procedures for making electrical connections to the unit, emphasizing safety and proper grounding.

Instructions for wiring and mounting a remote humidistat for automatic control.

Steps for adjusting process and reactivation dampers to achieve optimal operating temperatures.

Steps for cleaning or replacing the process and reactivation air filters.

Guidance on inspecting the HoneyCombe® wheel for correct rotation and signs of wear or contamination.

Instructions for inspecting the air seals that run along the HoneyCombe® wheel for wear.

How to verify the reactivation air outlet temperature is within the specified range.

General advice on preparing the unit for troubleshooting, especially with remote humidistats.

Steps to diagnose why the unit does not start when in automatic mode.

Troubleshooting steps when the fault light is illuminated but the unit should be operating.

Diagnosing and resolving low temperatures at the reactivation air outlet.

Identifying causes for reduced dehumidification, such as dirty filters or incorrect air volumes.

Troubleshooting steps when the HoneyCombe® wheel is not rotating despite the running light being on.

Procedures for testing the resistance and continuity of the heating elements.

Guidance on testing the thermistor that controls heating element operation.

Steps to verify the proper operation and wiring of the humidistat.

Instructions for inspecting and maintaining the drive motor, HoneyCombe® wheel, and seals.

| Brand | Munters |

|---|---|

| Model | HC-300 |

| Category | Dehumidifier |

| Language | English |

Loading...

Loading...