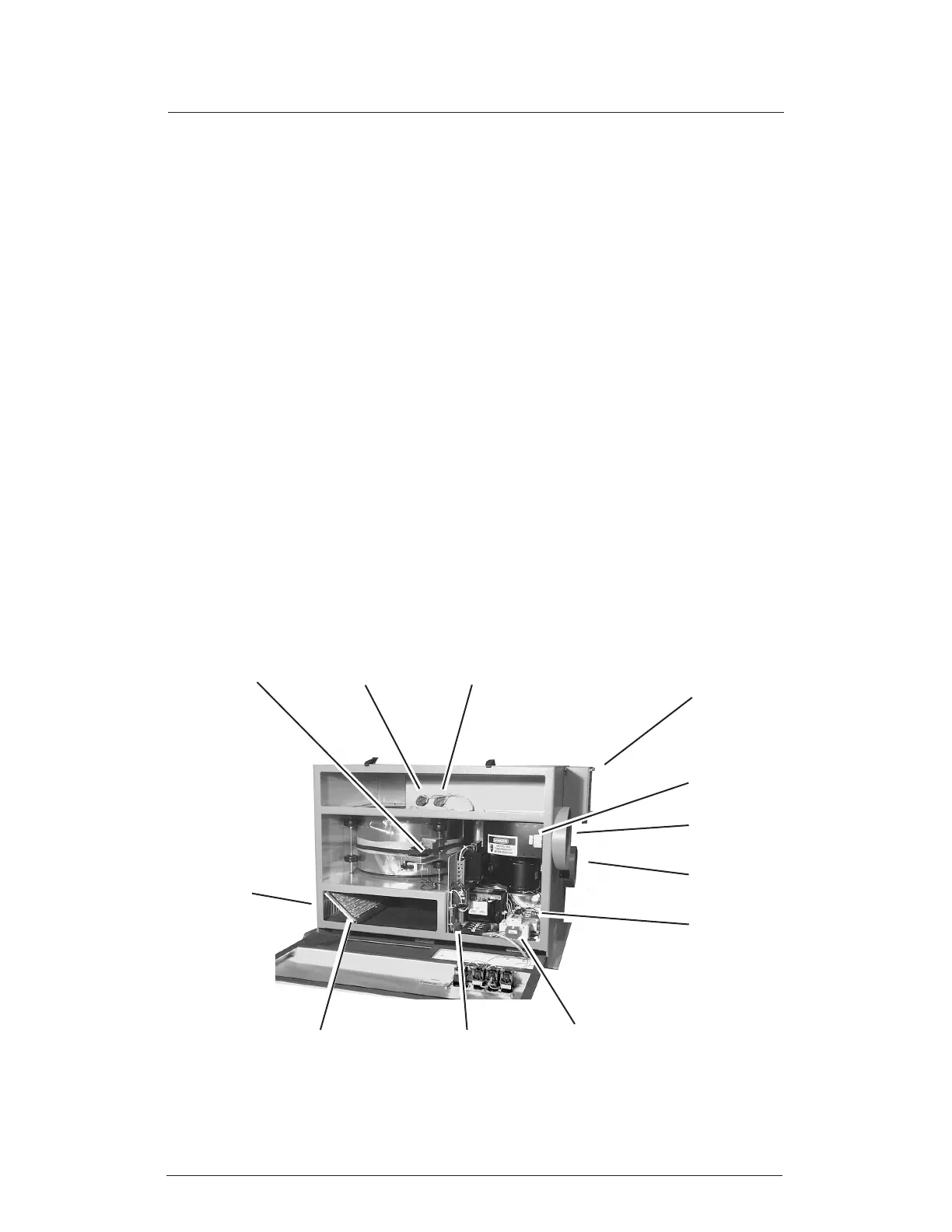

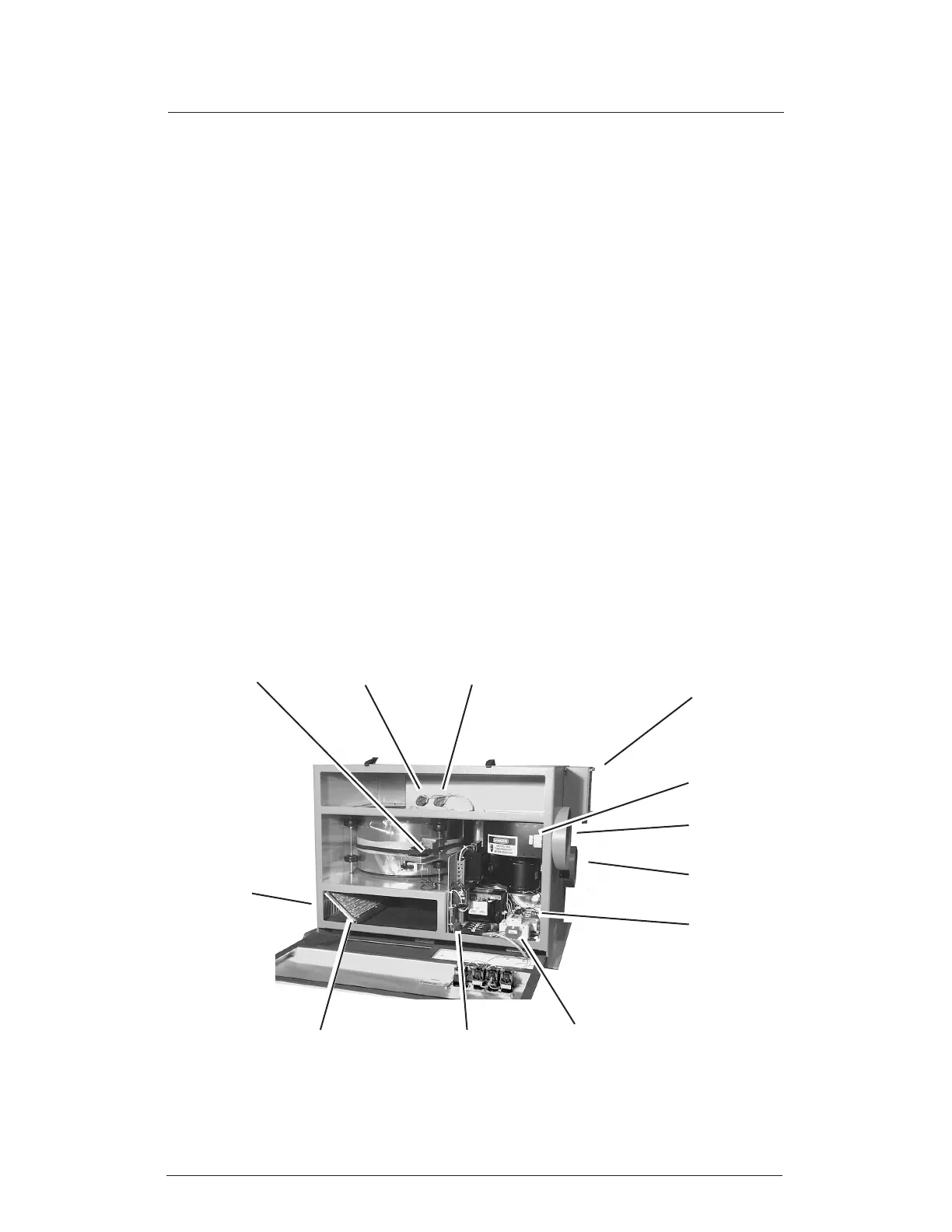

1-4

Circuit breaker

Drive motor and

belt tensioner

Reactivation fan

control board

Process air

inlet

Process

air blower

Process

air outlet

Temperature sensor

(TS01)

Temperature sensor

(TS02)

Solid state

power control

for heaters

(SSP1)

Process

air lter

FIGURE 1-4 - FRONT VIEW, COVER OPEN

located in the reactivation air stream after the wheel. This design allows reduced energy

consumption at low load levels.

The unit continues to run for a few minutes after the Auto/Off/Manual switch is turned off.

This “cool-down” cycle helps to protect the heating elements from overheating. During

the cycle, the reactivation blower continues to operate. The “cool-down” period is con-

trolled by a thermostat switch (TS02).

1.4 PROTECTIVE CIRCUITS

The HC-300 has several sensors and circuits which protect the machine and operator

from possible problems. A temperature switch (TS01) is located just downstream of the

heater. This sensor will tell the control circuits if the elements overheat (temperature

above 320°F). If this happens, the Fault indicator will light and the machine will stop. To

reset the machine, wait until the unit cools to normal temperature. Turn the Auto/Off/

Manual switch off, then on again.

The wiring for each heating element includes a fusible link. This link will open if the

element overheats. If this happens, the HC-300 will continue to operate, but will not

dehumidify the process air. To correct this, nd the cause of the overheat condition and

replace the fusible link.

If a blower motor is jammed, it will start to draw a large amount of electrical current. If

one of the motors detects this condition, that motor will shut itself down. The rest of the

unit will continue to operate, unless an overheat fault is triggered. The affected motor will

reset itself automatically.

Entrance for

power

connection

Reactivation

air inlet and

lter

Reactivation

air outlet

Loading...

Loading...