1-2

The next job is to move this moisture out of the wheel. As we said, the desiccant will give

up moisture when it is heated. When it is heated, and the moisture released, we say it

is “reactivated.” In the HC-300, a stream of “reactivation” air is taken from outside the

controlled space and heated using an electric heater. This heated air is forced through

the channels in the HoneyCombe

®

wheel. The desiccant releases the moisture into the

heated air stream. Finally, the damp reactivation air is vented outside. At this point, the

moisture has been moved from the storage room to the wheel, then from the wheel into

the outside air. The process is complete.

You may have noticed that, at one moment, we’re using the wheel to pick up moisture,

and a moment later, we’re heating the wheel to drive off the moisture. In the HC-300,

both actions are happening at the same time, on different sections of the wheel.

1.2 ABOUT THE HC-300

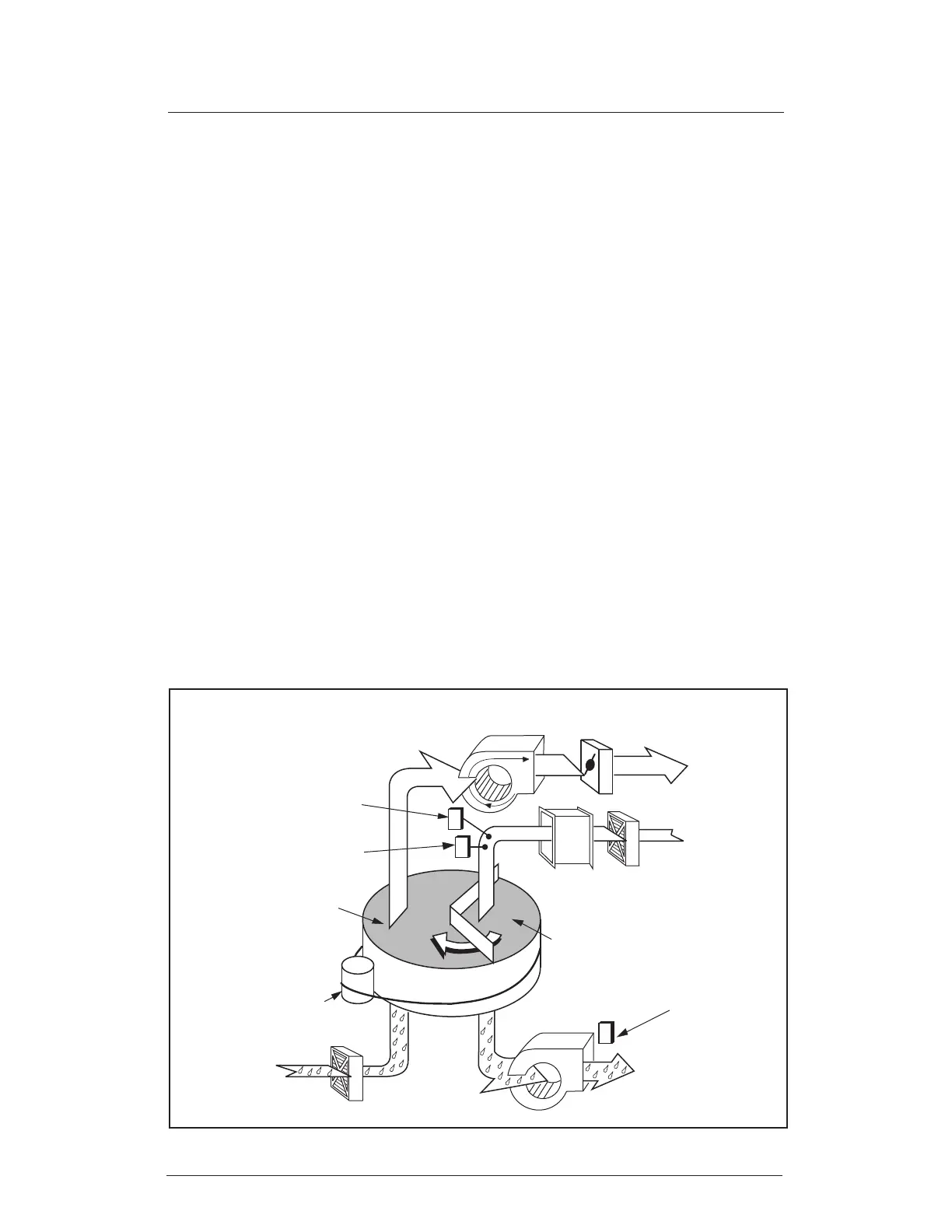

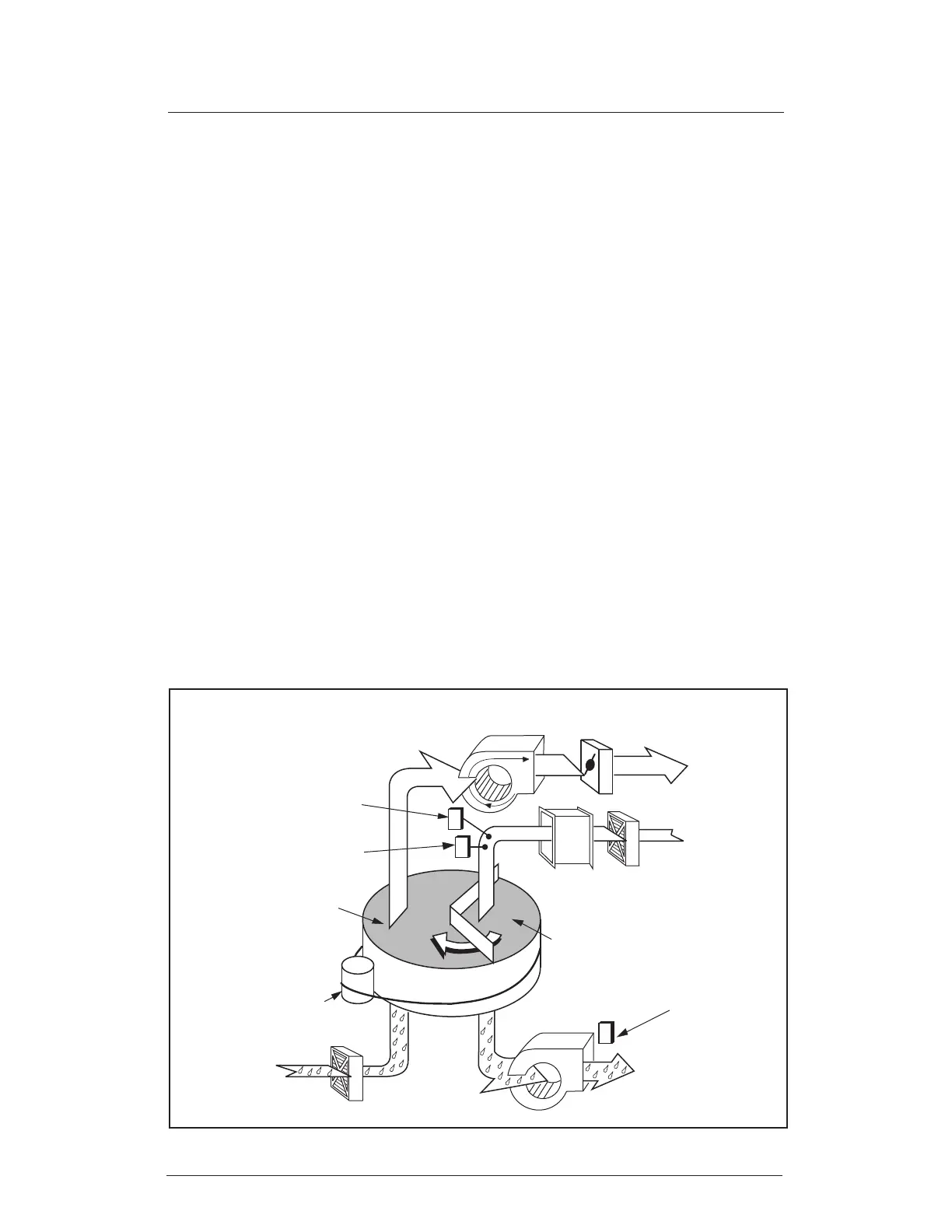

This is a simplied explanation of the operating principle. Figure 1-2 shows how we put

this principle to work in the HC-300. You can still see the parts we discussed in the last

Figure – the HoneyCombe

®

wheel, process air stream and reactivation air stream. We

have also added a number of other parts:

• Two sets of seals to separate the two streams of air (damp process air and the

heated reactivation air)

• Blower, damper and lter for the process air

• Blower and lter for the reactivation air

• Temperature sensors

• Electric heating elements for the reactivation air

FIGURE 1-2 - HC-300 IN OPERATION

Desiccant wheel

Heater

Filter

Process

air outlet

(dry air)

Blower

Drive

motor

Process air inlet

(moist)

Reactivation

blower

Reactivation

air outlet

(moist)

Temperature

sensor

TS02

Reactivation

sector of wheel

Process air

damper

Process

sector of wheel

Filter

Overheating

sensor

TS01

Reactivation air

temperature sensor

TSE1

Loading...

Loading...