AP-76942_Rev 1.0 Page 1/19

Dear customer,

Each ink has its own specific drying speed and drying characteristics, which has an influence on

its periodical maintenance cycle.

To maximise the life-time of all parts which are exposed to ink, it is crucial to carry out some easy

but important maintenance.

The most important maintenance actions are:

Wash away ink remainders from parts which are not (easily) accessible, avoiding that the ink

dries out, possibly causing blockage.

Regularly remove ink remainders from accessible parts.

Hereafter, tailored to each ink type, you will find simple guidelines explaining how you can

maintain excellent print quality and avoid that parts wear untimely.

Overview

When using the VJ-1614 it is important to perform periodic maintenance. This will help you

maintaining excellent output quality and avoid parts to wear untimely. Depending on your current

ink setup, follow the required periodical maintenance scheme.

1) When using Eco ink

2) When using UMS ink

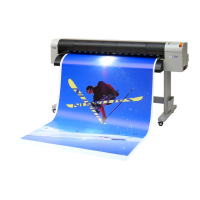

ValueJet 1614

Regular maintenance using Mutoh UMS or Eco-Ultra ink

Loading...

Loading...