2200LZJE-HO-C6-N_2013.12.

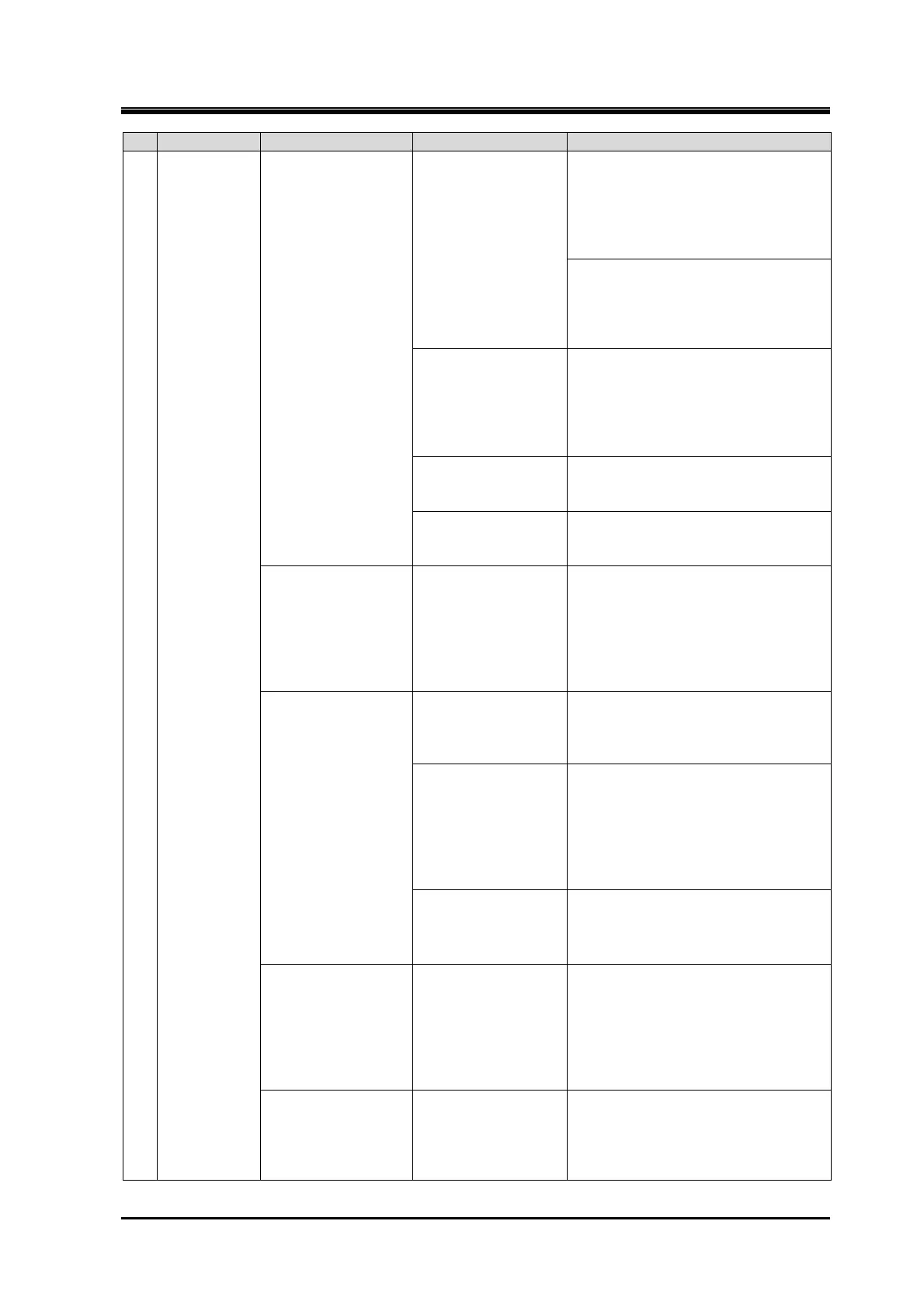

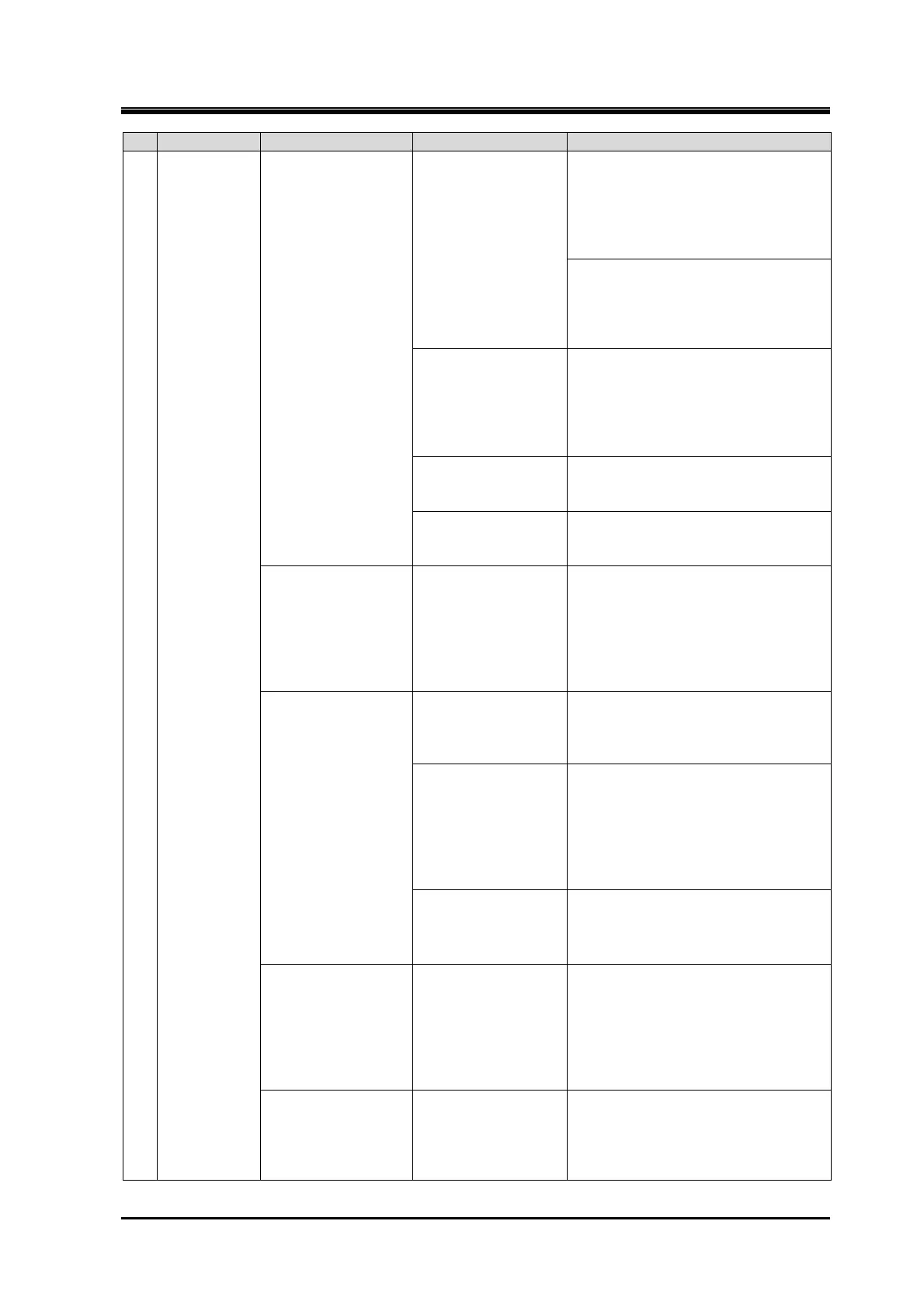

Chapter 6 Troubleshooting

Compound 2-stage Screw Compressor 2016**C

6-6

Symptom Direct cause Root cause Action

08

Leak from

mechanical

seal

Sliding surface is

roughened due to

overheating.

Started and

stopped too many

times.

* In case of

standard

equipment, "four

or more times per

hour" is

considered

"frequent/too

many".

If heat load is less than the level set

by the equipment's design

conditions, review the operating

conditions and set control such that

equipment is started/stopped less

frequently.

In case of capacity control

malfunction, see "Capacity control

malfunction" in item No. 11.

The amount of

lubricant contained

in refrigerant gets

smaller, resulting in

decreased

viscosity.

In case of liquid flow-back, remove

the cause(s).

If oil heater or devices on its control

circuit are defective, replace the

defective part.

Overheated

operation

See the causes in item 02,

"Insufficient refrigerant flow".

Oil supply

temperature is high.

See the causes in item 07, "Oil

supply temperature is high".

Machine is stopped

for a long time.

(No oil film on

sliding surfaces)

User-specific

conditions, such as

intermittent heat

load

If machine is sometimes stopped

longer than a week, take either of

the following measures: (i) Manually

operate oil pump alone and turn the

rotor shaft of the compressor.

(ii) Attach an oil pot for supply oil to

the seal cover.

Deteriorated part(s) Hardened O-ring If deteriorated over time, replace.

For other specific causes, see the

causes/action for symptom

"Overheating of sliding surface".

Swelled O-ring

* This occurs when

the lubricant of

refrigerating

machine contains

large amount of

refrigerant.

In case of liquid flow-back, remove

the cause(s).

If oil heater or devices on its control

circuit are defective, replace the

defective part.

Deteriorated seal

ring/mating ring

If deteriorated over time, replace.

For other specific causes, see the

causes/action for symptom

"Overheating of sliding surface".

Incompatibility of

lubricant and

operating

conditions (such as

working

temperature range

or refrigerant)

Unsuitable lubricant

was selected, or

operating

conditions have

changed after

installation of the

equipment.

If possible, review the operating

conditions.

If not, see "4-1 Lubricant

(Refrigerant Oil)" to select suitable

lubricant and replace the whole

quantity.

Poor contact of

sliding surfaces

Foreign matter

attached to sliding

surfaces, due to

contaminated

lubricant.

Replace the whole quantity of

lubricant.

Install bypass filter to oil supply line.

Loading...

Loading...