W415-3101 / B / 01.09.23

38

IOM

IOM

H18.4.2A

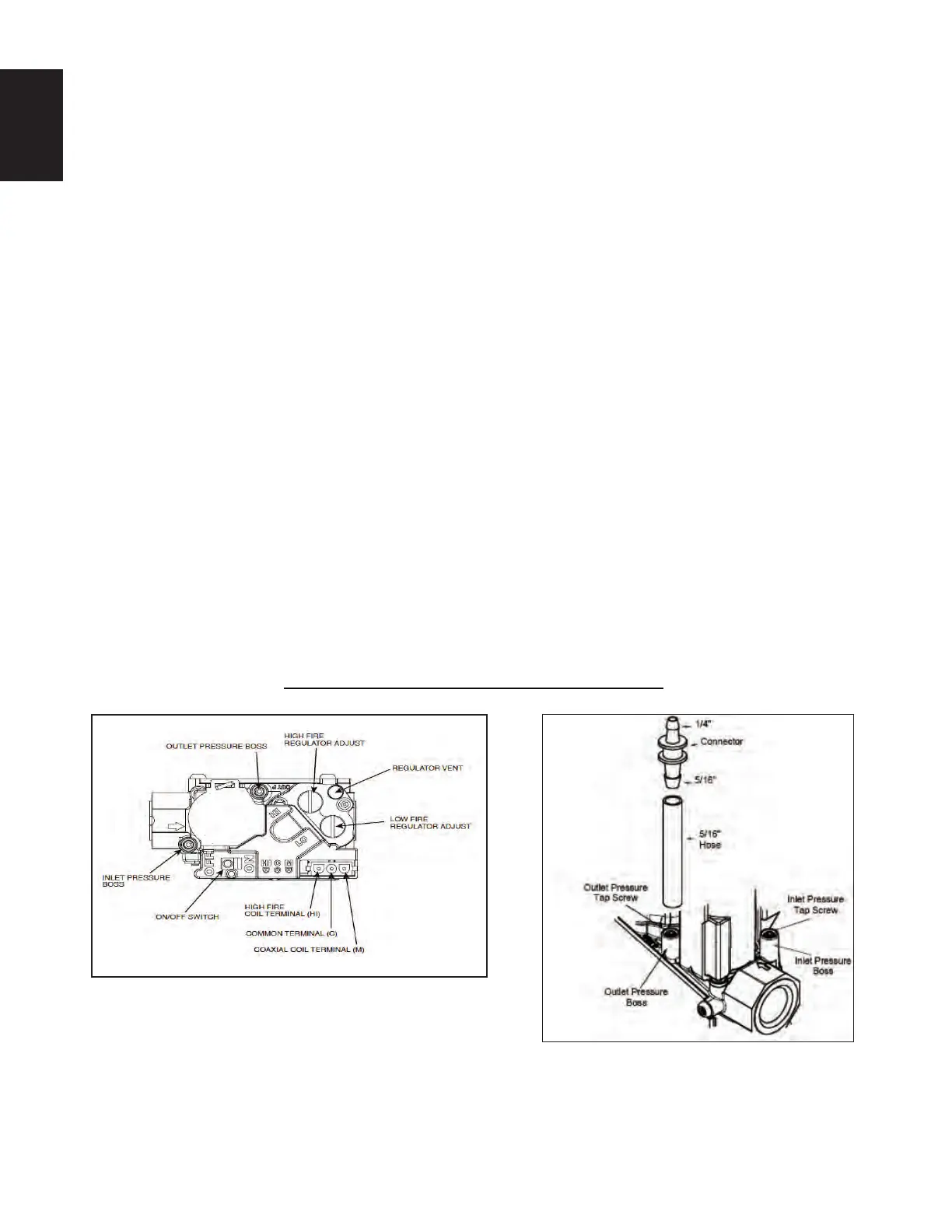

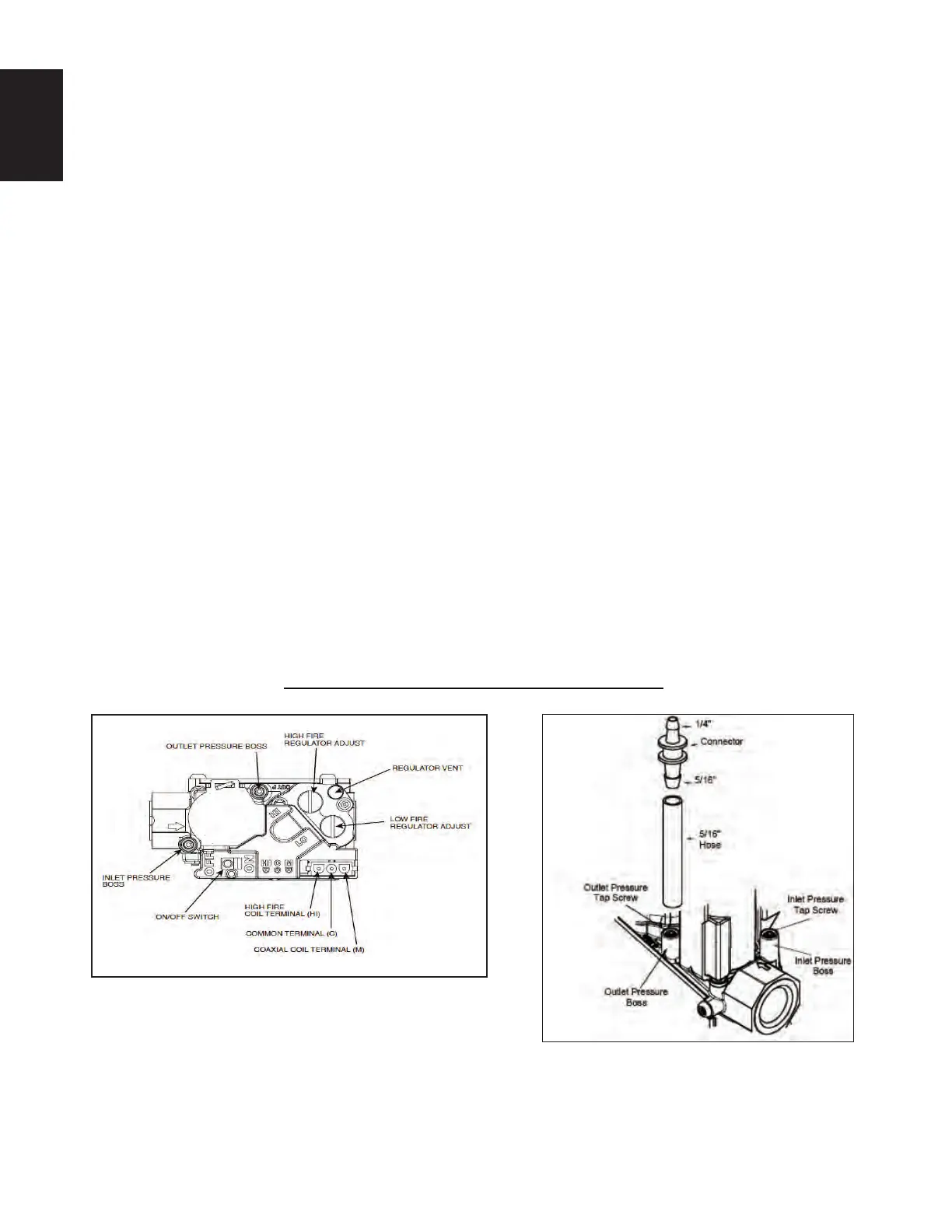

WHITE-RODGERS 36G54 TWO STAGE GAS VALVE

1. Turn off the gas and electrical supply to the furnace.

2. Back inlet pressure test screw (inlet pressure boss, see FIGURE 31) counterclockwise out one turn

maximum, with a 3/32” Allen wrench. Attach a hose and calibrated U-tube or digital manometer to the inlet

pressure boss. Hose should overlap boss 3/8”. The manometer must have a scale range of at least 0” to

15” of water column.

3. Turn ON the gas and electrical supply and operate the furnace and all other gas consuming appliances on

the same gas supply line. Using a leak detection solution, check for leaks around the gas valve/manifold

connection and the burner orifi ces. Repair any leaks before continuing.

4. Measure furnace gas inlet pressure with burners fi ring. Inlet pressure must be within the range specifi ed

on the furnace rating plate. 5-10.5” w.c. (Natural Gas) or 11-13” w.c. (LP).

If the inlet pressure diff ers from the rating plate, make the necessary adjustments to pressure regulator,

gas piping size, etc. and/or consult with local gas utility.

5. Turn off gas and electrical supply to furnace, remove the manometer hose from the inlet pressure tap

boss, and tighten the inlet pressure tap screw using the 3/32” Allen wrench. (Clockwise, 7 in-lb minimum).

6. Turn on the gas supply and electrical power to the furnace.

7. Using a leak detection solution, check for leaks at pressure boss screw. Bubbles forming indicate a leak.

SHUT OFF GAS AND FIX ALL LEAKS IMMEDIATELY!

8. Turn gas back on and test inlet pressure boss with leak detector.

9. If working on a natural gas system, contact the gas utility. They may insist on any service regulator

adjustments being made by their own staff .

If problems were encountered with obtaining enough pressure, fi rst examine the gas piping system to ensure

that it is correctly sized. Pipe sizing is specifi ed in CAN/CSA-B-149.1 & 2, and in NFPA 54 / ANSI Z223.1. Be

sure to check for restrictions, partially closed valves, etc.

In some circumstances, high inlet pressure can be remedied with the use of an in line appliance regulator. If

an in line appliance regulator is used, ensure that it has the capacity to adequately handle the gas volume

required by the furnace and any other appliances receiving gas from the header serving the furnace.

13.4 CHECKING THE INLET GAS PRESSURE

FIGURE 26 - VALVE PRESSURE CHECK KITFIGURE 25 - WHITE RODGERS 36G54 GAS VALVE

Loading...

Loading...