Parameter Default Description

Dig.In.2/3 delay

t = XX [s]

1 Delay of digital inputs 2 and 3.

Digital inputs 1 and 4 have a fixed delay of 1 second.

Change PASSWORD1

Press ENT

By pressing the ENT key it is possible to change the installer level password (level 1) (default 001).

9.10. Connectivity parameters

Parameter Default Description

Language

XXXXXXX

English Language of communication with the user

BTLE connection

ON / OFF

ON Enable BTLE communication

MODBUS address

XXX

1 MODBUS address from 1 to 247

MODBUS baudrate

XXXXX

9600 MODBUS baudrate from 1200 bps to 57600 bps

MB data format

XXXXX

RTU

N81

MODBUS data format: RTU N81, RTU N82, RTU E81, RTU O81

EEPROM writing

ON/OFF

OFF Setting the writing mode of the parameters transmitted via MODBUS:

ON: the datum is saved in EEPROM

OFF: the datum is not saved in EEPROM

Change PASSWORD1

Press ENT

By pressing the ENT key it is possible to change the installer level password (level 1) (default 001).

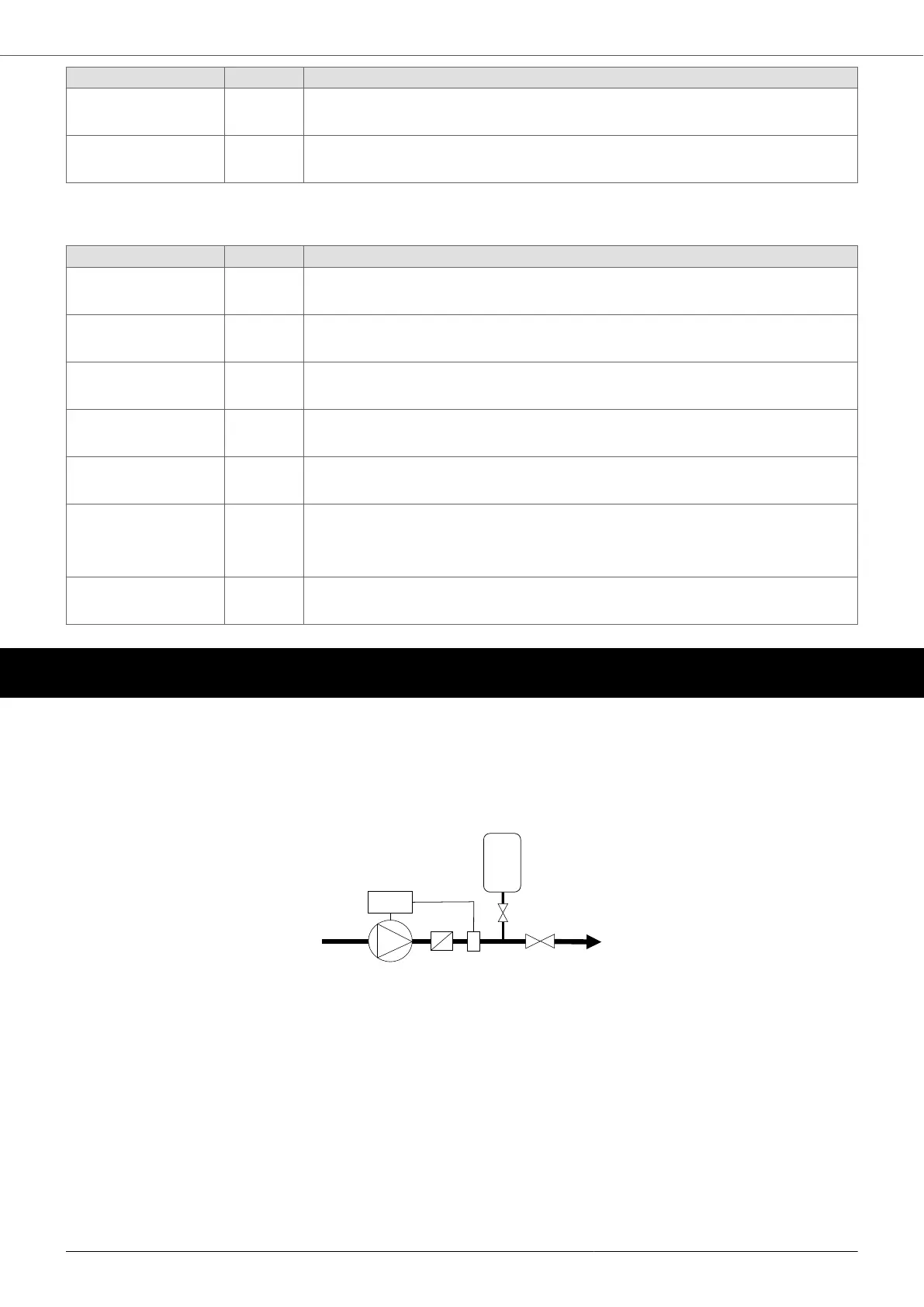

10. Constant pressure operation

10.1. Introduction

TheVASCO - VAriable Speed COntroller can manage the running speed of the pump in such a way as to keep the

pressure constant as the water demand changes. A pressure sensor placed as close as possible to the pump is

used for this purpose.

1: Inverter; 2: Pump; 3: Check valve; 4: Pressure vessel; 5: Gate valve; 6: Gate valve; 7: Pressure sensor

10.2. The pressure vessel

In water systems equipped with inverters, the function of the pressure vessel is to compensate for losses (or

minimum water consumption) and maintain pressure when the pump is stopped, thus avoiding excessively frequent

start/stop cycles. It is of fundamental importance to correctly choose the volume and the pre-charge pressure of the

pressure vessel. Too small volumes do not allow effectively compensating the minimum water consumption or the

losses when the pump is stopped, while too high volumes make it difficult for the inverter to control the pressure.

It is generally sufficient to place a pressure vessel with a volume of about 10% of the maximum flow rate required,

considered in liters/minute.

Example

VASCO - VAriable Speed COntroller

43

Loading...

Loading...