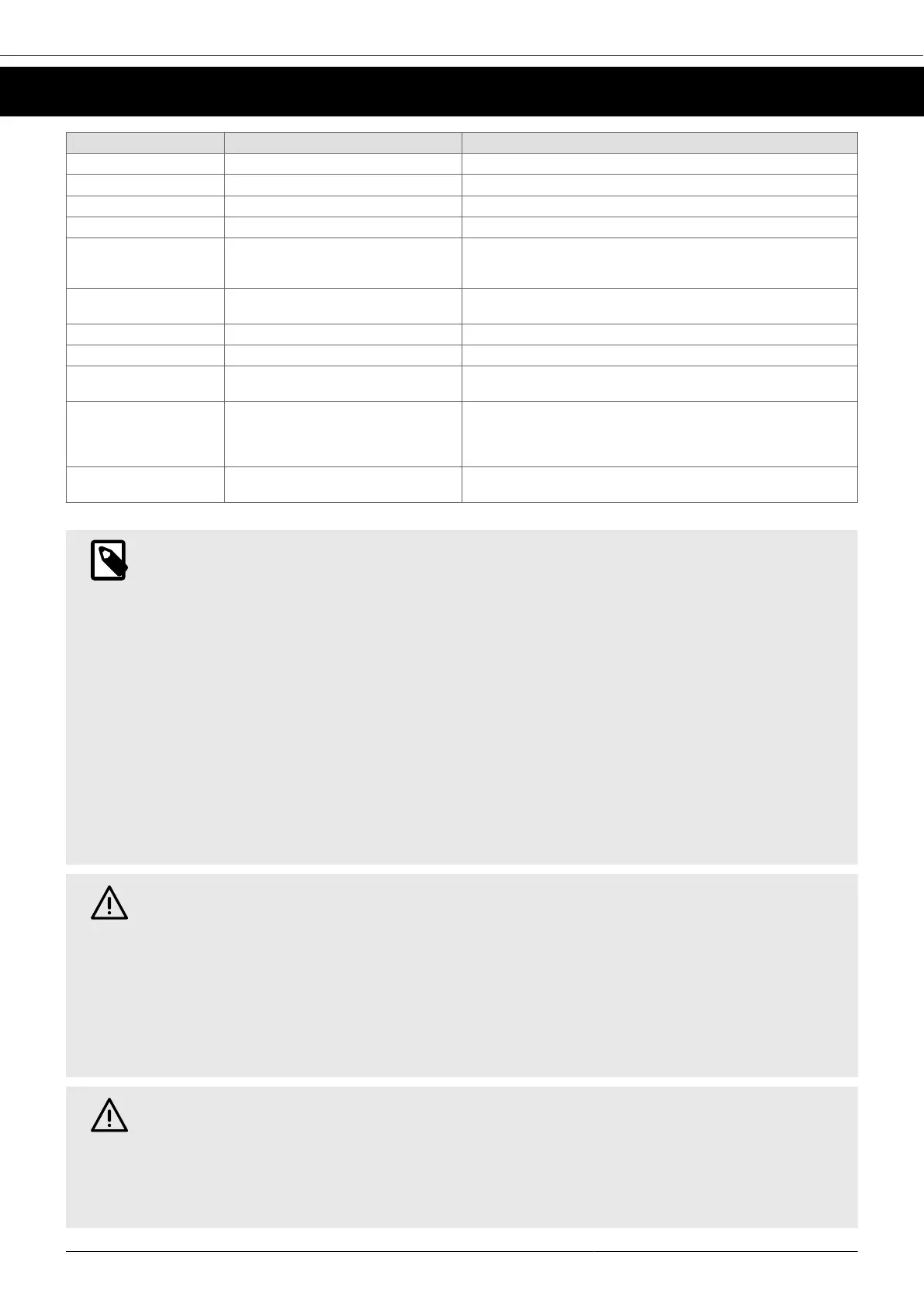

14. Warnings

Warning Description Possible solutions

W01 ACTIVE DIG.IN. 1 Digital input 1 has been activated. • Check the configuration and connections to digital input 1.

W02 ACTIVE DIG.IN. 2 Digital input 2 has been activated. • Check the configuration and connections to digital input 2.

W03 ACTIVE DIG.IN. 3 Digital input 3 has been activated. • Check the configuration and connections to digital input 3.

W04 ACTIVE DIG.IN. 4 Digital input 4 has been activated. • Check the configuration and connections to digital input 4.

W20 TEMP. DERATE The inverter is limiting the maximum

motor frequency to keep the inverter

temperature below the maximum limit.

• Check the possible solutions for the alarm A03 OVER TEMP. INV..

W21 OVERLOAD 15V 15V power supply overload. • Check the absorption of the loads and any short circuits connected

to the 15V power supply

W22 EEPROM COM. No communication with EEPROM • Contact the technical support service.

W23 EEPROM FAULT Failure in EEPROM • Contact the technical support service

W25 ALARM SLAVE X In control mode COMBO, the master

has detected an alarm in the X slave.

• Check the status of the XX slave unit indicated by the master.

W26 NO WATER The power factor (cosphi) of the motor

read by the device is permanently be-

low the value set in the parameter Dry

run cosphi.

• Check that the pump is properly primed.

• Check that the pump is turning in the correct direction.

• Check that the parameter Dry run cosphi is set correctly.

W27 BLOCK START/

STOP

The START/STOP buttons have been

locked.

• Press the START or STOP button for at least 5 seconds to release

the lock.

NOTE

With three-phase asynchronous motors, the correct value to which parameter Dry run cosphi is to be

set depends on:

• The type of motor (construction and winding data). Generally, three-phase surface motors have a

higher rated cosphi than submersible motors having the same power rating.

• The type of pump (hydraulic performance and power consumption curve).

• The power supply characteristics (voltage and frequency).

In general, the parameter Dry run cosphi may be set to 60% of the nominal cosphi shown on the

pump's data plate.

Parameter Dry run cosphi must also be determined empirically at the end of the installation. In the

presence of centrifugal pumps with three-phase asynchronous motor, a simple method consists in

starting the pump at the rated frequency and, paying attention to the sustainability of the system,

completely closing the delivery and then reading the measured cosphi value on the display (or on the

App). Parameter Dry run cosphi must therefore be set to 10% less than the cosphi value read under

closed flow condition.

CAUTION

The electronic water shortage protection based on parameter Dry run cosphi works correctly only

with centrifugal pumps equipped with three-phase asynchronous motors.

In the presence of permanent magnet motors it is not possible to base the water shortage protection

on the cosphi reading; it must be based on the absorbed power, instead.

When parameter Motor type is set to Synchronous PM, parameter Dry run cosphi takes on the

meaning of a percentage of the absorbed power.

In the presence of other types of pumps and motors, it is advisable to contact the technical support

service.

WARNING

If parameter Dry run cosphi is set too low, the electronic water shortage protection may no longer be

effective.

Typically, it is recommended not to go below the value of 0.5 with centrifugal surface pumps and 0.4

with centrifugal submersible pumps equipped with asynchronous three-phase motor.

Setting parameter Dry run cosphi to 0 completely excludes the water shortage protection.

VASCO - VAriable Speed COntroller

54

Loading...

Loading...