SECTION5–MAINTENANCESCHEDULEANDSERVICEPROCEDURES

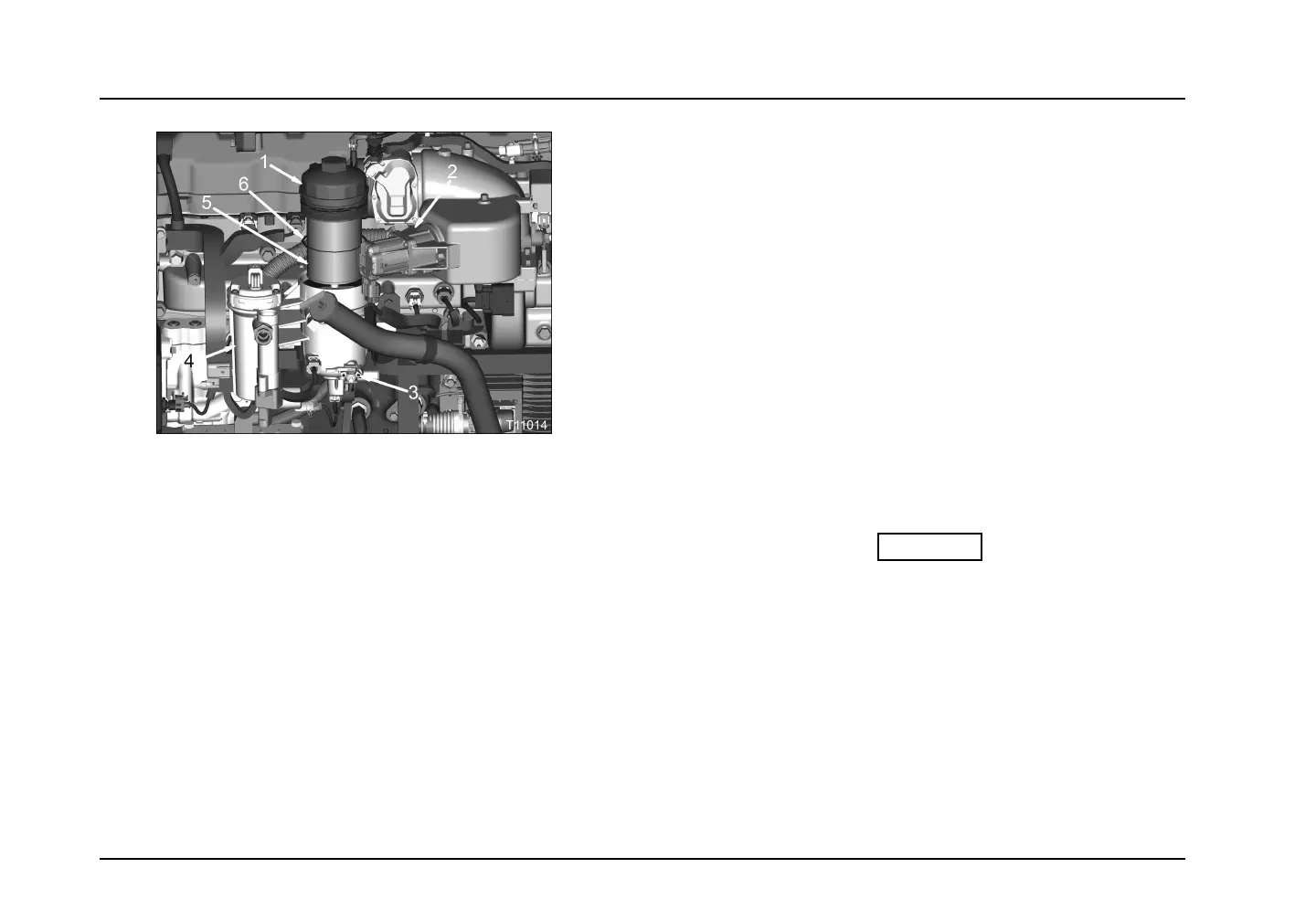

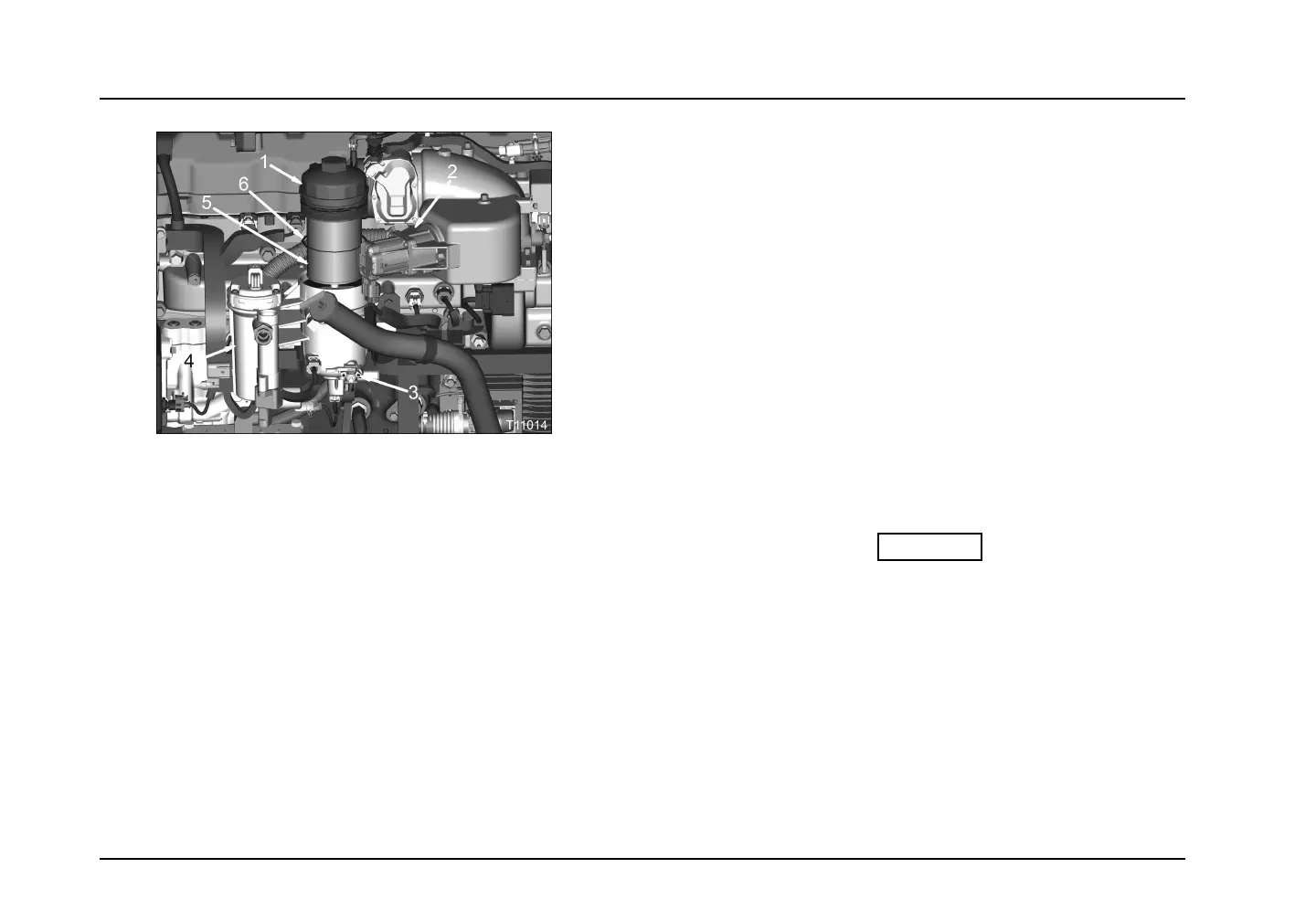

Figure38Fuellterremovalandinstallation

1.Fuelltercover

2.ExhaustGasRecirculation(EGR)valve

3.Waterdrainvalve

4.Fuelpump(fuelstrainerlocation)

5.Fuellterelement

6.FuelltercoverO-ring

10.Continueturningthefuelltercoveruntilloose.Removethe

fuelltercoverandelementfromthefuellterhousing.

11.Removethefuelltercoverfromthefuellterelementby

holdingtheelementverticallyandpushinguponthecover.

Thecoverwillsnapoffthefuellterelement.Disposeofthe

fuellterelementaccordingtoapplicableregulations.

12.RemoveO-ringfromthefuelltercover.DiscardO-ring.

13.CoatanewfuellterO-ringforthefuelltercoverwithclean

dieselfuelandinstallontothefuelltercover.

14.Attachfuelltercovertothefuellterelement.Securethe

fuelltercovertothefuellterelementbypushingthefuel

ltercoverontothefuellterelement.Thefuelltercover

willsnapontothefuellterelement.

15.Coatthreadsoffuelltercoverwithcleandieselfuel.

16.Installafuellterelementwithcoverintothefuellter

housing.Slowlylowerthefuellterelementintothefuel

lterhousing,untilfuelltercoverisreadytobesecuredto

thefuellterhousing.

17.Securethefuelltercoverandelementtothefuellter

housingbyturningthefuelltercoverclockwiseuntil

nger-tight.

CAUTION

Topreventenginedamage,tightenfuelcoveron

fuellterassembly.

18.Usinga23mmwrenchtightenfuelltercoverto30N·m(22

lbf·ft).

19.Depressclutchpedalifequipped.

20.TurntheignitionswitchtoONforapproximately60seconds,

allowingthefuelpumptoprimethefuelsystem.SeePriming

theFuelSystem(page46).

Page78

Loading...

Loading...