SECTION5–MAINTENANCESCHEDULEANDSERVICEPROCEDURES

1.Setparkingbrakeandshifttransmissiontoparkorneutral.

2.Disconnectthewiringharnesstotheelectricfuelpumpby

pushingdownonthetabofthewiringharnessconnector

andpullingawayfromtheelectricfuelpump.

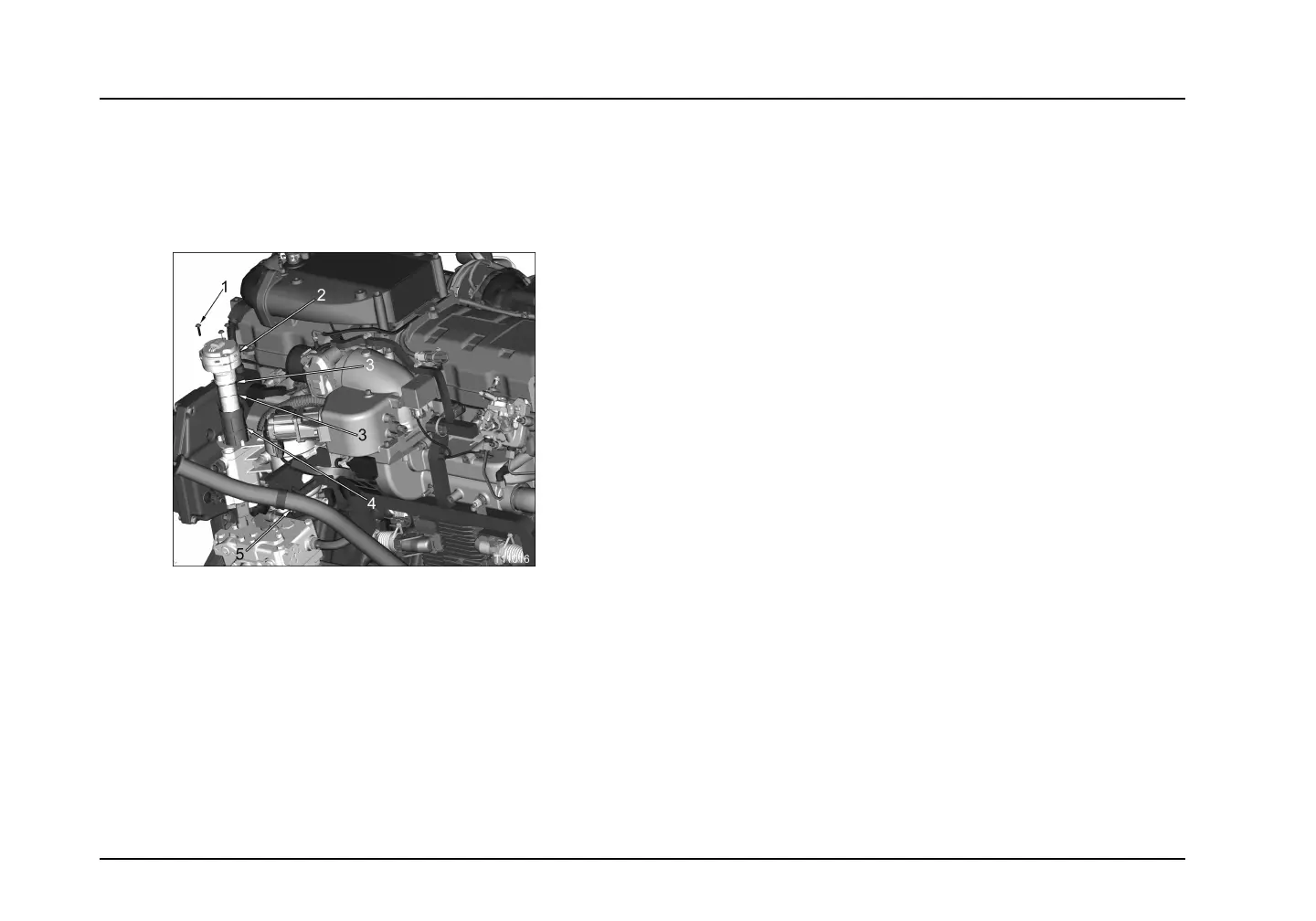

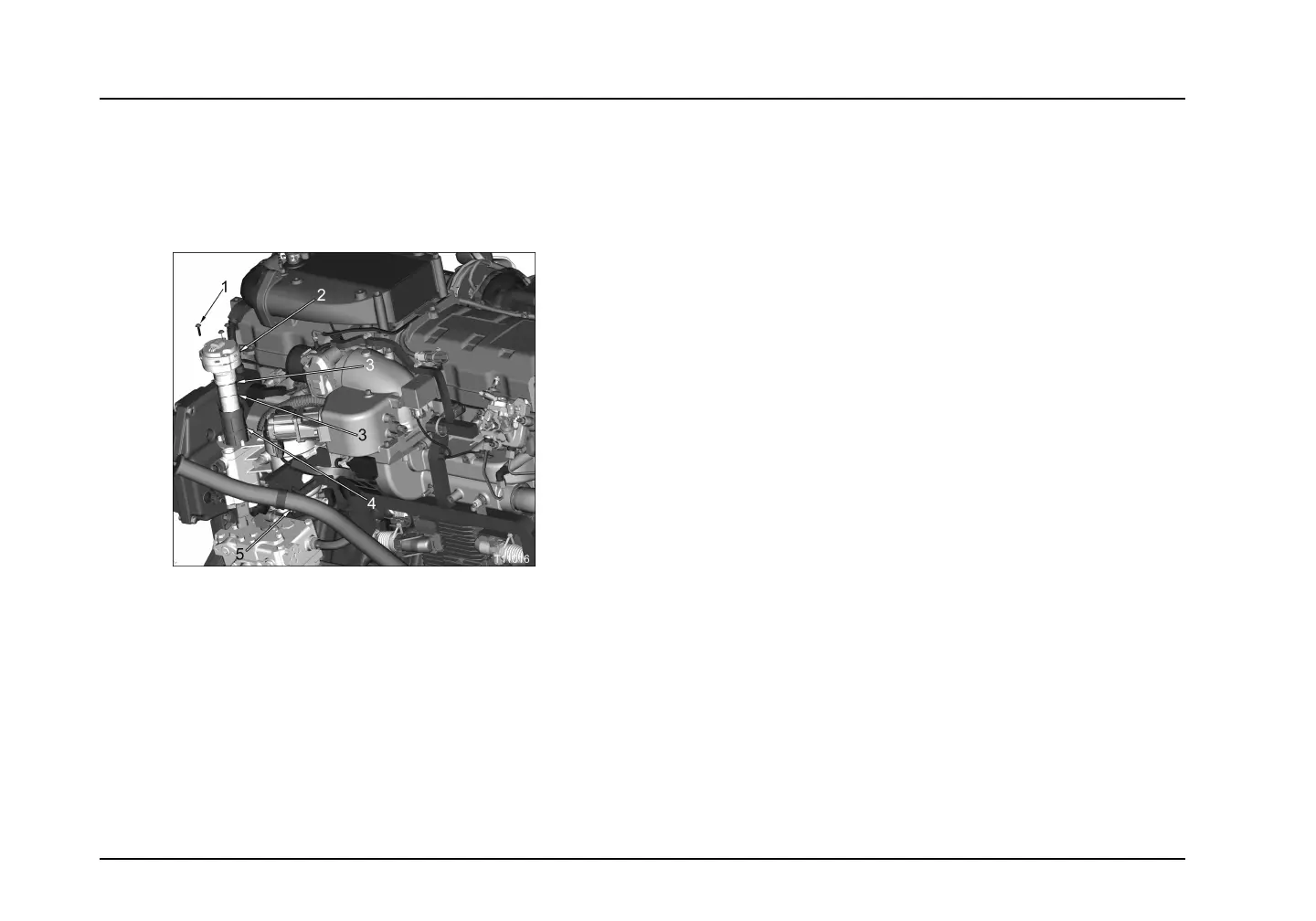

Figure40Fuelstrainer

1.Pumpcoverbolt(3)

2.Electricfuelpump

3.FuelpumpO-ring(2)

4.Fuelstrainer

5.Fuellterhousing

3.Removethreepumpcoverbolts.Donotdiscardbolts,these

willbereusedwheninstallingthefuelpump.

4.Usingaatbladescrewdrivergentlypryupthefuelpump

fromthefuellterhousing.

5.Oncethefuelpumpisloose,pullthefuelpumpoutofthe

fuellterhousing.

6.RemovethefuelstrainerandO-ringsfromthefuelpump.

DiscardtheO-rings.

7.Dooneofthefollowing:

•Iffuelstrainerisnotdamaged-cleanfuelstrainer,

coattwonewO-ringswithcleandieselfuel,andinstall

O-ringsontofuelpump.

•Ifstrainerisdamaged-coattwonewO-ringswith

cleandieselfuel,andinstallO-ringsontofuelpump.

Installanewfuelstrainerontothefuelpump.

8.Lowerfuelpumpassembly(withstrainer)intothefuellter

housing.Alignthethreeboltholesinthefuelpumpcover

withtheboltthreadsofthefuellterhousing.Placepalm

ofhandontopoffuelpumpandpushdownrmly.Thiswill

seatthefuelpumpintothefuellterhousing.

9.Securethefuelpumptothefuellterhousingbyinstalling

andtighteningthethreepumpcoverboltsto5N·m(44lbf·in).

10.Depressclutchpedalifequipped.

11.TurnignitionswitchtoONforapproximately60seconds

allowingfuelpumptoprimethefuelsystem.

Page80

Loading...

Loading...