25

© by NECTA VENDING SOLUTIONS SpA 0012 Colibrì

REGENERATING THE SOFTENER UNIT (OPTIONAL)

Only a 2-litre ion-exchange resin softener unit can be used

on these machines.

The resins should be regenerated at least once a week or

even more frequently depending on the hardness of the

water from the mains used to supply the machine (see

table below).

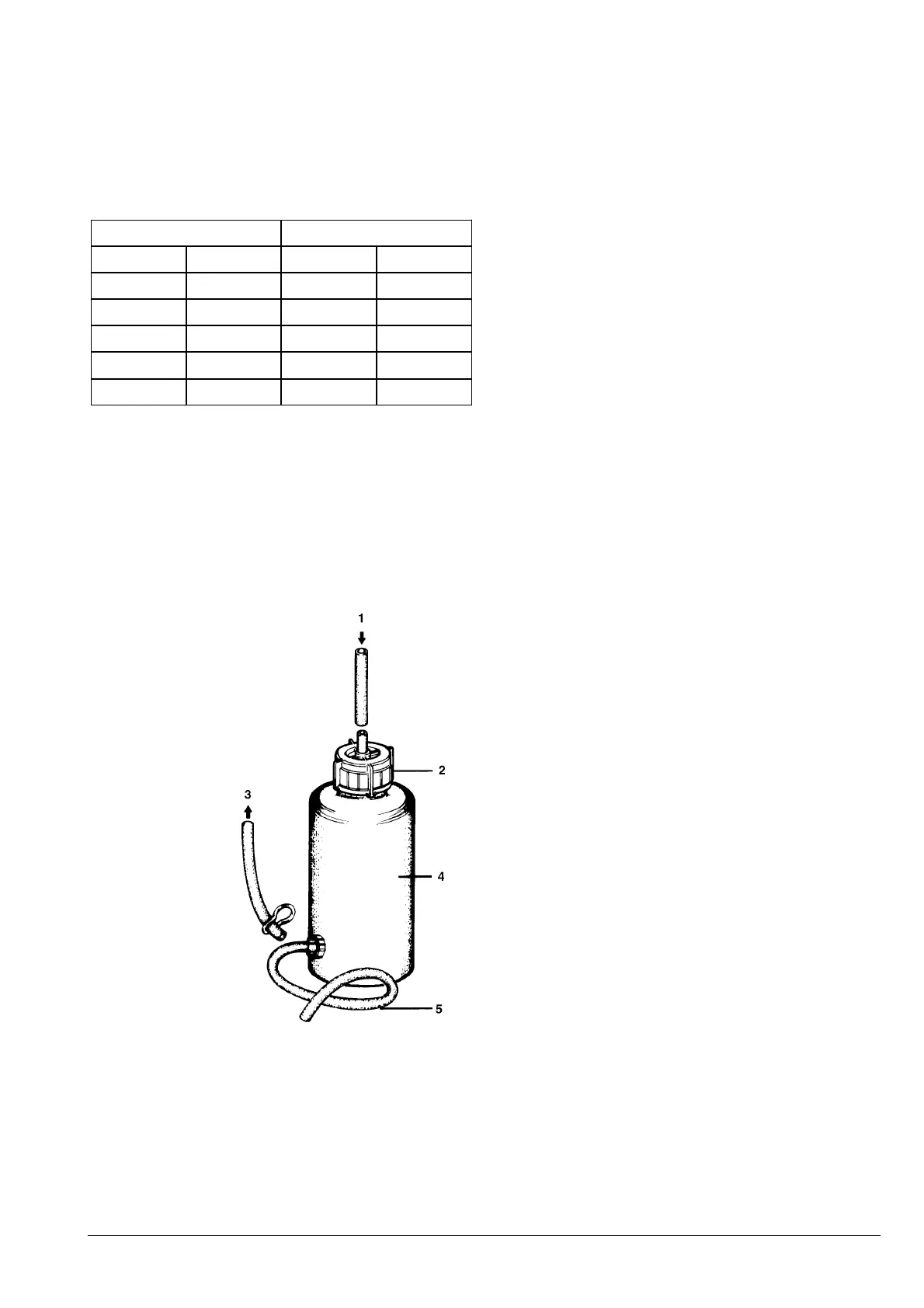

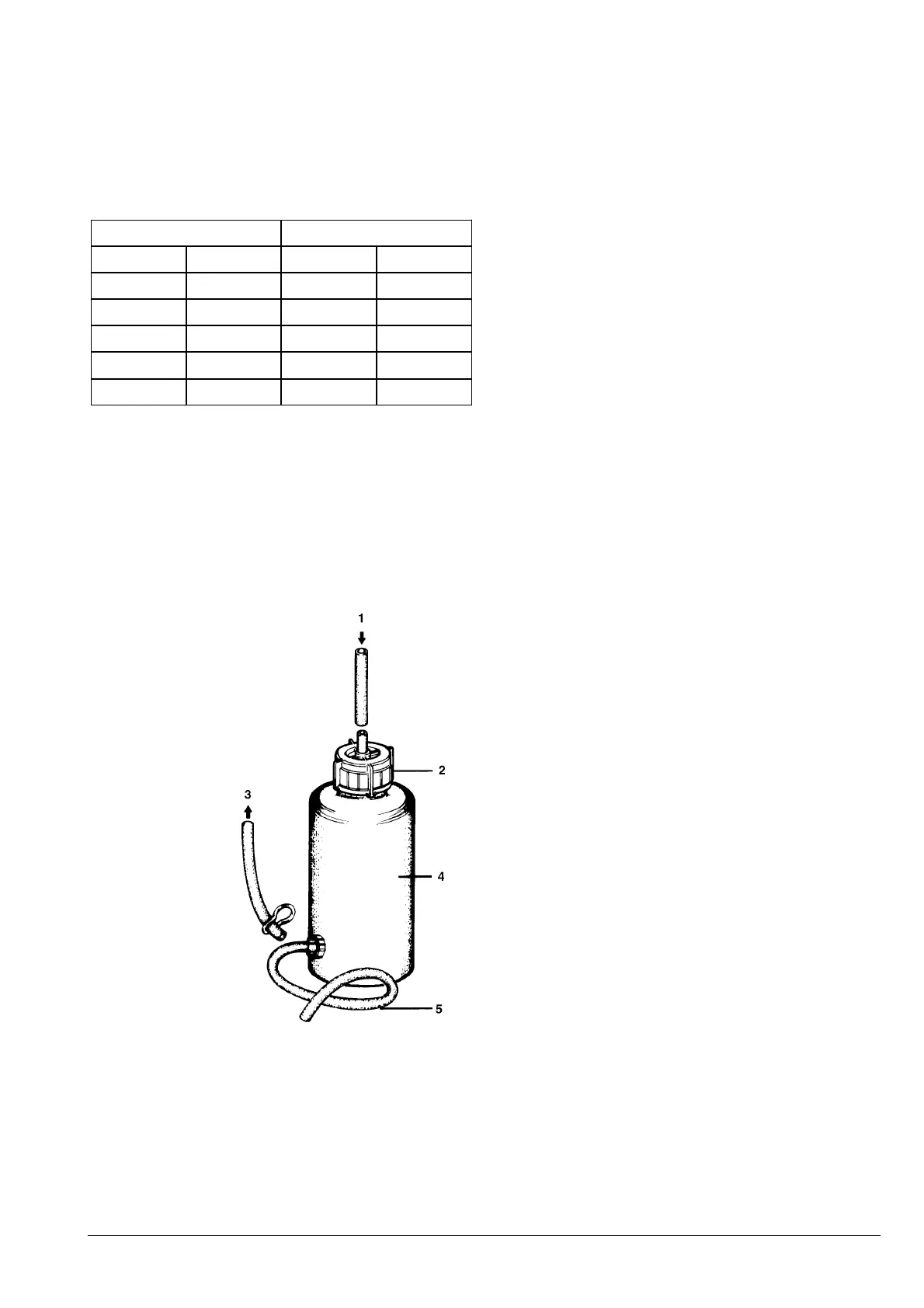

Fig.. 18

1 - From the tap

2 - Cap

3 - To the machine

4 - Softener unit

5 - To the drain

ssendrahretaWsnoitcelesforebmuN

F°G°.cc06.cc031

016,500650082

022,1100820041

038,610091009

044,220041007

050,820011055

To regenerate the resins correctly do as follows:

- remove the softener unit from the cabinet and shake it

vigorously to eliminate any preferential paths which

may have formed;

- fill 0.5 Kg. of sodium chloride (ordinary salt);

- connect the side hose union to a tap and the middle

rubber-holder to a drain point; the direction of the water

flow must be

NECESSARILY

the one shown in the figure 18

ANNUAL SANITISING

At least once a year, or more frequently according to the

use of the machine and the quality of the inlet water, the

entire foodstuff circuit system must be cleaned and

sanitised in the following way:

- all parts of the hydraulic system in contact with food,

including the hoses, must be removed from the unit

and fully disassembled;

- wash all components with detergents, ensuring that all

visible residue and product films are mechanically

removed using brushes or similar tools, if necessary;

- all components must be soaked in a sanitising solution

for at least 20 minutes;

- the unit internal surfaces are to be cleaned with the

same sanitising solution;

- Thoroughly rinse and then reinstall the parts.

Before restarting the unit, the same sanitising pro-

cedure described in section "Sanitising the food-

stuff circuits and the mixers" should be repeated

with the components reassembled.

- adjust the water flow in such a way as to completely

dissolve the salt in 10 litres water within 25 minutes;

- during the regeneration operation, ensure that the sof-

tener unit is always full of water, bleeding any air which

may have entered;

- at the end of this operation ensure that outlet water is no

longer salted; it is advisable to check the hardness of the

water by means of appropriate chemical reagents: the

outlet water hardness should be 0° F.

Loading...

Loading...