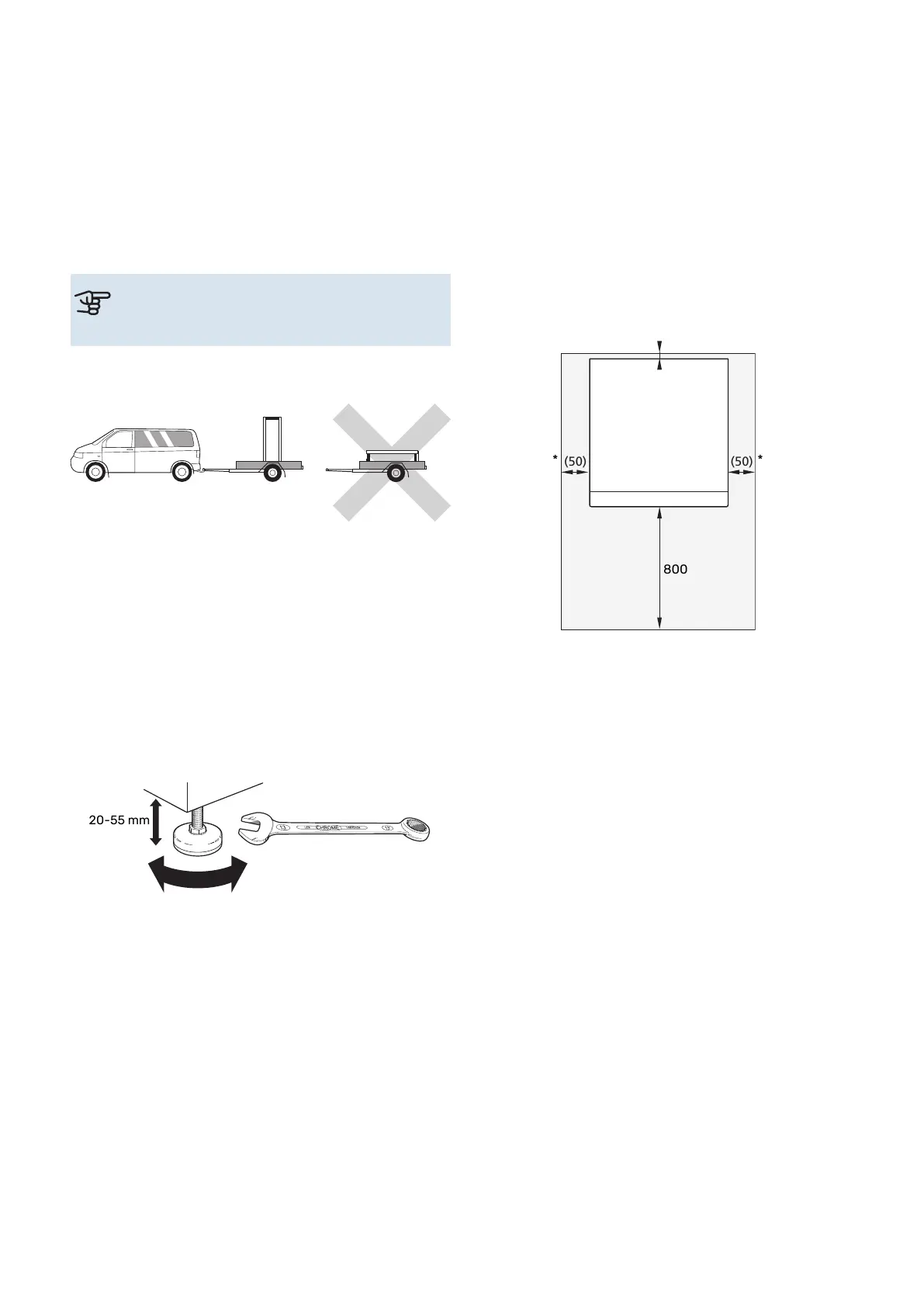

Transport

S1256 should be transported and stored vertically in a dry

place. When being moved into a building, S1256 may be leant

back 45 °.

Ensure that S1256 has not been damaged during transport.

Caution

The product can be tail heavy.

Remove the outer panels in order to protect them when

moving in confined spaces inside buildings.

EXTRACTING THE COOLING MODULE

To simplify transport and service, the heat pump can be

separated by pulling the cooling module out from the cabin-

et.

See page 63 for instructions about the separation.

Assembly

• Position S1256 on a solid foundation indoors that with-

stands water and the weight of the product.

• Use the product’s adjustable feet to attain a horizontal

and stable set-up.

30 - 50 mm

30 - 50 mm

15 - 40 mm

• Since water comes from S1256, the area where S1256 is

located must be equipped with floor drainage.

• Install with its back to an outside wall, ideally in a room

where noise does not matter, in order to eliminate noise

problems. If this is not possible, avoid placing it against a

wall behind a bedroom or other room where noise may be

a problem.

• Wherever the unit is located, walls to sound sensitive

rooms should be fitted with sound insulation.

• Route pipes so they are not fixed to an internal wall that

backs on to a bedroom or living room.

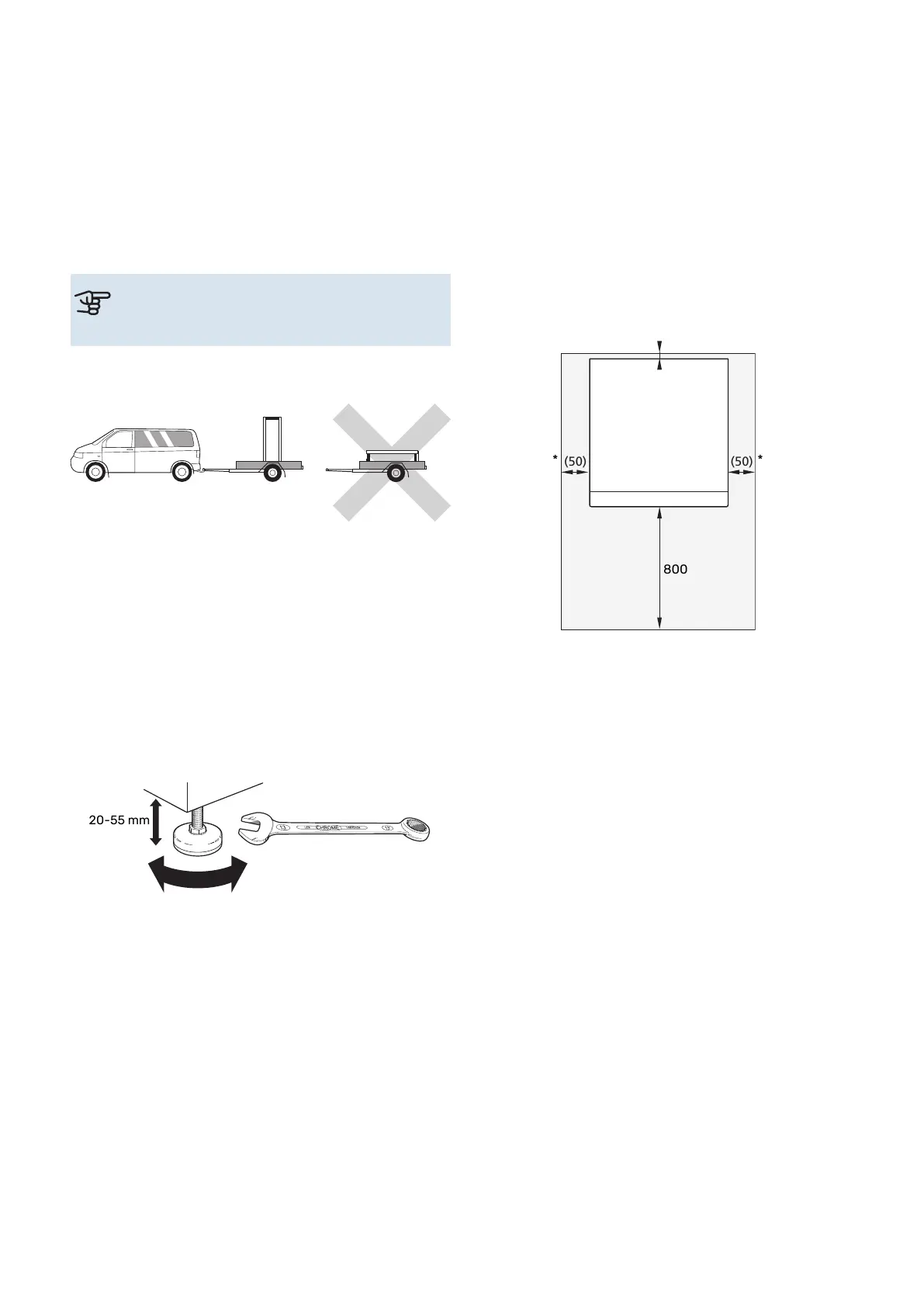

INSTALLATION AREA

Leave a free space of 800 mm in front of the product. Ap-

prox. 50 mm free space is required on each side, to allow

the side panels to be removed (see image). All service on

S1256 can be carried out from the front, however the right-

hand panel may need to be removed. Leave free space

between the heat pump and the wall behind (and any routing

of supply cables and pipes), to reduce the risk of any vibra-

tions being propagated.

* A normal installation needs 300 – 400 mm (any side) for

connection equipment, e.g. level vessel, valves and electrical

equipment.

NIBE S1256Chapter 2 | Delivery and handling6

Delivery and handling

Loading...

Loading...