ENGLISH – 11

EN

4.5 INITIAL START-UP AND ELECTRICAL

CONNECTIONS TEST

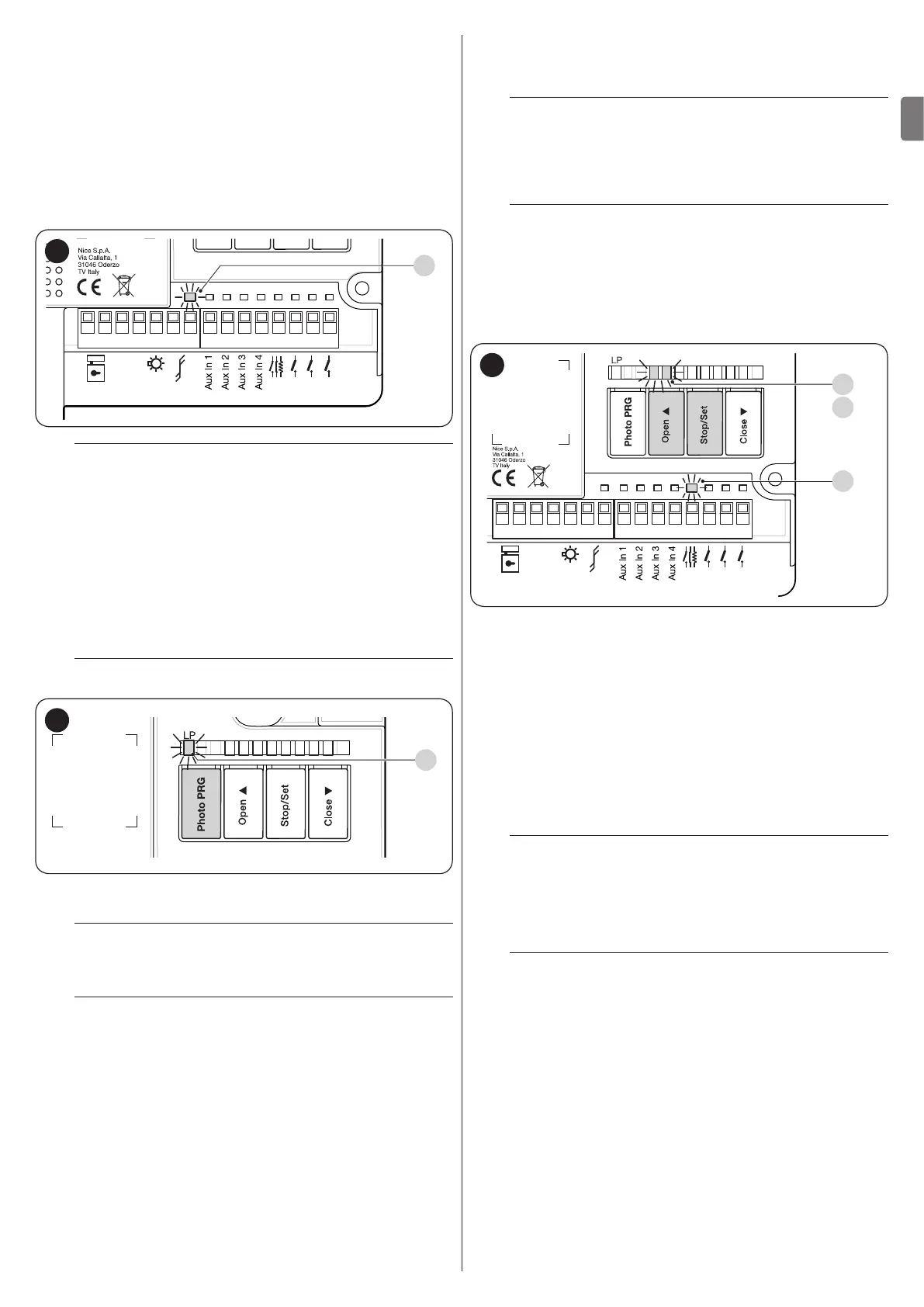

After powering the control unit, carry out the following checks

(“Figure 12”):

1. after a few seconds, check that the “Bluebus” (A) LED

ashes regularly with one ash per second

2. check that the LEDs of the photocells, both TX (transmis-

sion) and RX (reception), ash. The type of ash emitted

in this phase is not signicant

3. check that the warning light connected to the “Flash” out-

put is turned off.

0V

EL

OGI

Bluebus

2

Close

Open

SbS

Stop

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

A

12

a

If any one of these tests fails, disconnect the pow-

er supply to the control unit and check the various

electrical connections made previously.

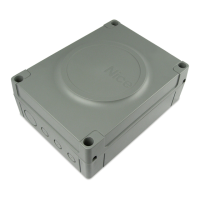

4.5.1 Programming with relay photocells

If relay photocells have been connected to the control unit to

inputs AUX 1 (PHOTO), AUX 2 (PHOTO 1) and AUX 3 (PHOTO

2), the “Photocell programming” function must be activated.

To do this:

– press and hold the Photo PRG button until the “LP” LED

switches on.

l

Any inputs not used must be kept free.

L5 L6 L7 L8L4L3L2L1

LP

13

To deactivate the “Photocell programming” function, press the

Photo PRG button until the “LP” LED switches off.

l

If the “Photocell programming” function is activat-

ed (“LP” LED lit), inputs AuxIn1, AuxIn2, AuxIn3,

AuxIn4 cannot be used as limit switches.

l

For further details on the operation with and without

the phototest, consult the wiring diagrams under

the “Wiring diagram with relay photocells without

phototest” and “Wiring diagram with relay photo-

cells with phototest” paragraphs.

4.6 LEARNING OF CONNECTED DEVICES

After the initial start-up, the control unit must recognise the de-

vices connected to the “Bluebus” and “Stop” inputs.

l

The control unit automatically learns the relay pho-

tocells connected to inputs AUX1, AUX2 and AUX3

only if the operation described under the “Program-

ming with relay photocells” paragraph has been en-

abled.

l

The learning phase must be carried out even if no

device is connected to the control unit.

The control unit can individually recognise the various devices

connected, thanks to the learning procedure, and detect possi-

ble anomalies.

For this to occur, the device learning procedure must be carried

out whenever a device is added or removed.

L5 L6 L7 L8L4L3L2L1

0V

EL

OGI

2

SbS

Stop

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

S

L1

L2

14

LEDs “L1” and “L2” on the control unit (“Figure 14”) emit some

slow ashes to signal that the learning procedure must be car-

ried out.

To do this:

1. simultaneously press and hold the

f

and

g

buttons

2. release the buttons when LEDs “L1” and “L2” start ash-

ing quickly (after roughly 3 seconds)

3. wait a few seconds until the control unit has completed the

device learning phase

4. once this phase terminates, the “Stop” (S) LED must be lit

and LEDs “L1” and “L2” must switch off (LEDs “L3” and

“L4” could start ashing).

l

If the AUX In 1-2-3 inputs are used to connect the

relay photocells, leave any inputs not used free.

4.7 SELECTING THE TYPE OF MOTOR (FOR

HYDRAULIC MOTORS ONLY)

m

This phase must only be carried out if hydraulic mo-

tors are connected to the control unit.

In hydraulic actuators, the thrust to keep the gate closed is gen-

erated within a hydraulic circuit that remains constantly under

pressure. When time and wear reduce the hydraulic circuit’s

tightness, after a few hours it may occur that the internal pres-

sure decreases, potentially causing the gate leaves to open

slightly. To overcome this problem, the control unit has a “Pres-

sure maintenance” function that, if activated, every 4 hours that

the gate has been closed triggers a brief “close” command in

order to fully close the leaves and reload the pressure of the

hydraulic circuit. To activate the function, refer to the “Level 1

programming (ON-OFF) - Function L8” paragraph.

Loading...

Loading...